Automate quality control and inspection with AI

Accelerate defect detection, boost uptime with 24/7 real-time monitoring, and maintain consistent product standards

Talk to our AI inspection expertsOur Clients

Manual inspection follows the 1:10:100 rule. $1 in prevention costs $10 in detection, and $100 to fix if a faulty product reaches customers. Large, organized, and customer-oriented companies prioritize faster, smarter inspections to avoid compliance issues, customer safety consequences, and save time and money.

Our AI-powered quality inspection system enables smarter and faster quality check by codifying the logic of what constitutes a ‘defect’ through detailed categories, rules, and examples. Using this annotated data, our AI engineers train ML models to detect defects and develop a machine vision quality inspection system. The system learns and adapts continuously to your new product designs, material variations, and emerging defect types. Whether you are in manufacturing, energy and utilities, oil and gas, telecom, or other industries, Softweb Solutions can embed the power of automated visual inspection with AI into your production workflows.

An error can cost 100X more once it reaches consumers. With smart quality inspection using AI, you can stop it at 1X. We can help.

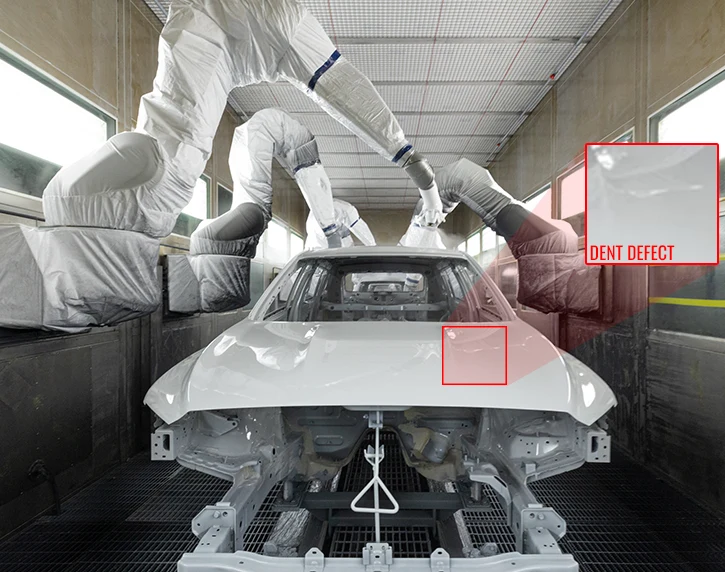

Let's talkSurface defects

Easily identify scratches, dents, cracks, and stains across all product surfaces. Our AI-powered computer vision for quality control solution analyzes surface topology, texture patterns, and reflectance properties to identify surface defects. It can identify defects as small as 0.1mm on metals, plastics, glass, and composite materials.

Dimensional accuracy

Accurately measure hole spacing in circuit boards, out of tolerance specification, and alignments in mechanical assemblies. Our computer vision AI capabilities verify dimensional data in milliseconds. It uses laser scanning, structured light projection, and high-resolution imaging for precise engineering requirements validation.

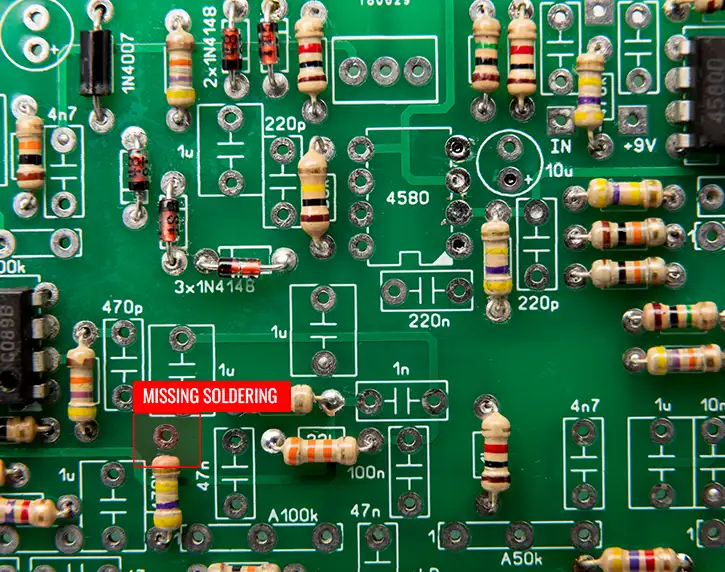

Assembly verification

Quickly identify missing components and misaligned parts before they advance to packaging or shipping. AI-powered quality inspection system learns from thousands of assembly examples to detect missing, reversed, or orientation issues instantly. These automated workflows improve assembly quality and reduce field failures.

Color and shade consistency

Precisely detect color variations and shade differences across product lines and packaging materials. Our computer vision for quality control analyzes wavelengths across visible and near-infrared ranges to detect variations that are not visible to the human eye. It ensures brand consistency and reduces customer complaints.

Text, barcode, and label accuracy

Accurately verify text, serial numbers, and barcode readability across product packaging. We train OCR systems on your diverse fonts and printing materials to verify content against product databases in real-time. This confirms every printed item meets industry-specific guidelines for pharmaceuticals, food products, and regulated materials.

Welds and joints

Fully examine porosity in aluminum welds, incomplete penetration in steel joints, and oxidation in titanium seams. AI-powered quality inspection uses metallurgical databases to identify incomplete fusion, crack initiation, and material inclusions. Automated seam verification adjusts parameters in real time, ensuring consistent joint quality.

Packaging quality

Efficiently inspect package seals, fill levels, and tamper-evident features. Our high-speed vision systems use infrared thermal analysis and ultrasonic inspection to assess package integrity and fill accuracy. The system removes defective items while maintaining production speed and meeting safety and compliance standards.

Counting and quantity verification

Accurately count components in kits, hardware, and assemblies to meet customer specs and industry standards. Automated visual inspection with AI separates overlapping items, distinguishes similar components, and adjusts for varying orientations in packaging containers. It assures correct quantities in every packaged product.

Verify hole diameters, slot dimensions, and aperture positioning to fractions of a millimeter. The machine vision quality inspection system checks if holes are round, slots are the right depth, and everything lines up where it should be for proper function.

Assess product edges for tiny chips, rough spots, and uneven shapes. High-resolution sensors detect the smallest edge deformations that could affect how parts fit together. The system confirms smooth finishes and proper geometric specifications.

Detect dust specks, oil residues, and foreign particles that stick to product surfaces. Automated visual inspection with AI uses textural analysis, specialized lighting, thermal imaging, and CNN models for contamination detection and classification.

Ensure containers hold the correct amount of liquid, powder, or other materials inside. An AI-powered quality inspection system uses various sensory inputs and machine learning algorithms to detect overfill and underfill conditions in containers.

Find sharp edges, metal fragments, and hazardous protrusions with computer vision. Automated inspection applies deep learning, gradient-based methods, Grey Level Co-occurrence Matrix (GLCM) technique, and more to identify safety hazards.

Validate brand logos, designs, and printed patterns look right and appear in the correct spots. Computer vision for quality control captures images, applies YOLO and R-CNN, compares images with the golden template, and verifies logos, designs, and patterns.

Identify misaligned components, crooked labels, and off-center assemblies. Smart quality inspection using AI combines machine vision and deep learning for positional and angular analysis and to perform precise alignment checks.

Recognize incorrectly positioned parts, upside-down components, and rotational errors. AI-based quality control solution sees, interprets, and compares parts against a set of standards to identify any misplacement or rotational issues.

Transform your quality control capabilities with customized AI-based quality control solutions designed for specific use cases.

Talk to our experts

Defect classification

Identifies and categorizes multiple defect types

Real-time processing

Performs high-speed inspection without slowing production

Automated decisions

Provides pass/fail classification with instant alerts

Adaptive learning

AI learns and improves as new defects appear

System integration

Works with ERP, MES, and production systems

Analytics dashboard

Delivers insights into defect trends and process optimization

Multi-modal imaging

Supports video, X-ray, thermal, or microscopic imaging

Alert management

Sends notifications when quality thresholds are exceeded

Data export

Exports inspection results to external quality systems

Custom workflows

Creates specific inspection processes for different products

Self-calibration

Adjusts sensors and cameras based on reference materials

Traceability integration

Provides traceable records of each product’s quality data

Automated quality checks replace costly manual work, reduce rework expenses, and lower overall inspection spending.

AI-driven inspections identify even the smallest flaws, reduce human error, and deliver more consistent quality results.

Detect defects before products ship, prevent costly recalls, and protect customer trust with reliable automated inspection.

Inspections run at production speed, minimizing downtime, improving throughput, and enabling higher overall equipment use.

Expand inspections across new lines and facilities quickly by adding cameras and models, without major workforce growth.

Reduce scrap and material waste through accurate detection, supporting greener production methods and lower resource use.

Generate audit-ready quality records in real time, simplify regulatory reporting, and meet compliance deadlines with ease.

Access instant quality metrics on the line, detect deviations early, and make faster data-driven production corrections.

We deliver AI-based quality control solutions worldwide, helping manufacturers to detect defects earlier, reduce recalls, and meet compliance without slowing production.

We train AI models with domain-specific datasets, apply multi-angle imaging, and validate results against ground truth benchmarks to deliver 99% precision in defect detection.

No two lines are the same. That’s why we customize CNNs, object detection, and anomaly detection models to match your products, workflows, and inspection priorities.

Our automated inspection solutions connect with PLCs, MES, and ERP systems, providing real-time defect data, automated alerts, and audit-ready reports for compliance.

By reducing rework, waste, and recalls, our solutions help your company achieve sustainable production goals while enhancing customer trust.

We do not stop at implementation. From integration to ongoing support, we work alongside your team to make sure the solution delivers lasting value.

AI-powered quality inspection uses machine vision and deep learning to analyze images and detect defects automatically. It processes visual data in real time, classifying products as pass or fail. The system improves accuracy with every inspection by learning from new data.

It detects surface scratches, cracks, and deformations as well as micro-defects invisible to the human eye. AI also identifies contamination, misalignment, missing components, and seal integrity issues. Multi-modal imaging allows detection across metals, electronics, plastics, and packaging.

It replaces slow manual checks with fast, consistent inspections at production speed. AI ensures higher accuracy, fewer recalls, and real-time defect data for process improvement. Manufacturers gain both efficiency and confidence in meeting compliance standards.

Yes. AI systems connect with PLCs, MES, and ERP without disrupting operations. They integrate with cameras, sensors, and conveyors, delivering real-time results directly into existing workflows.

Yes. With high-resolution imaging and advanced algorithms, AI detects defects smaller than human vision can identify. This ensures precision in industries like semiconductors, aerospace, and healthcare.

AI models retrain quickly with new image data, allowing fast adaptation to design updates. This reduces downtime during product changes. Manufacturers can update inspection rules without reprogramming the system.

AI learns from feedback loops, comparing predictions with actual outcomes. This continuous refinement reduces false alarms and missed defects. Over time, accuracy improves while unnecessary rejections drop.

Yes. Computer vision runs alongside human inspectors, catching defects they may miss. It provides a second layer of assurance, boosting accuracy and consistency.

AI inspection detects defects caused by equipment wear, while predictive maintenance anticipates machine failures. Together, they reduce unplanned downtime and prevent defective output. The result is smoother, more reliable production.

It lowers inspection costs, reduces rework, and prevents recalls. Operations run faster with fewer stoppages, improving throughput. Companies also gain real-time insights for process optimization.

Begin with a pilot project on one production line. Collect defective images, train AI models, and validate accuracy against current inspection methods. Once proven, scale across facilities for maximum impact.

Bring AI-powered quality inspection to your production line

Book a consultation with our machine vision experts to see how your organization can benefit from automated quality control and inspection with AI.