Computer vision services

Automate your monitoring and reporting applications to recognize, capture and generate insights from images and videos.

Get project insights from expertsOur Clients

Softweb Solutions creates cutting-edge applications by integrating computer vision services with other systems such as ERP, POS, CCTV and diagnostic software to detect anomalies in production lines, analyze medical images, and identify products and people on social media, among other possibilities. It can also be integrated with machine learning operations to build a wide range of enterprise applications and cloud services. To meet the constraints of diverse industries, our team has designed artificial intelligence and computer vision-based applications with advanced components such as object classification, feature recognition, segmentation, pattern recognition, object detection, filtering, and so on. We can assist you in achieving such prototypes using minimal resources and no additional hardware support.

AI-powered defect detection ensures high-quality products. Our computer vision models deliver precision in manufacturing, construction, and inspection through real-time analysis, instantly capturing defects. Automate inspections, optimize maintenance, enhance quality control, and reduce costs.

Transform raw images into insights with AI-driven classification. Our models categorize images into predefined labels for automated tagging, quality assessment, and smart decisions. Ideal for retail, healthcare, security, and industrial applications, our solutions streamline workflows and extract valuable data.

Detect and extract objects from video based on trained AI models. then classify each object to enable intelligent video analysis to empower users with granular search, smart alerting and comprehensive reporting.

OCR services convert data into machine-editable text. It is the most-effective solution to capture data from printed or written text from a scanned document or image file. OCR ensures high-quality data conversion that is fast, accurate and efficient.

Label your images and take control of your training data while powering your computer vision apps with large data sets. Our image annotation services support image classification, object detection and recognition using tools like bounding box, polygon, polyline and key point annotation.

Identify multiple objects in an image and receive information about the location of the object in the image. Empower your enterprise-level apps with custom models that are capable of detecting individual objects in a given image along with their bounding box and label using our object detection service.

Images from cameras placed on the assembly line of 7 factories helped detect and prevent 112 component failures. No human skill/experience can match CV’s ability to achieve cent percent uptime, zero defect manufacturing and a consistent product line.

Ensure accurate package counting by utilizing automated counting systems. This eliminates manual counting and boosts accuracy and efficiency.

Verify package counts now ›

Verify proper closure of packet seals that prevents leakage or tampering, ensuring protection against contamination to maintain product freshness and quality.

Detect package defects ›Categorize product packaging by their size, volume, and dimensions. Ensure compatibility with product requirements such as protection from environmental sustainability and impact.

Classify your packages ›

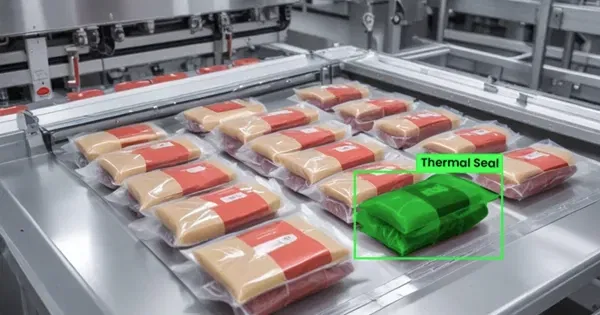

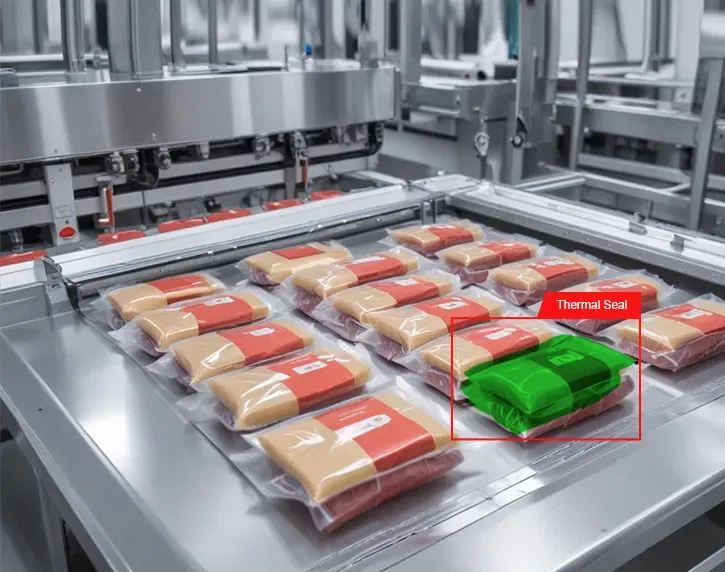

Evaluate the strength and durability of thermal seal, resistance to environmental factor, and width and consistency. This ensures secure closure, product freshness, and quality.

Check thermal seals ›Claim your free 1-hour AI vision strategy call and start building smarter, faster solutions

Talk to our experts!Cap closure inspection

Identify missing, misaligned, or damaged caps on bottles or containers. This ensures proper sealing and prevents leaks or contamination.

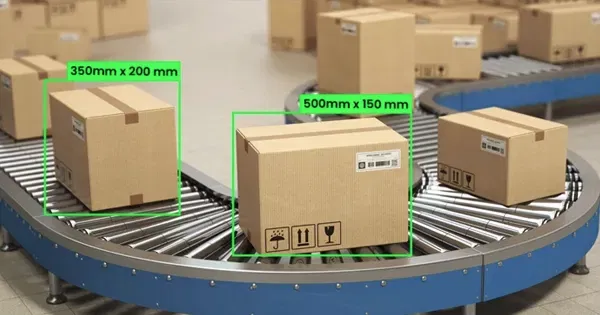

Dimension detection

Precisely measure product dimensions, ensuring consistency and adherence to specifications. This helps catch irregularities and potential packaging flaws.

Foreign object detection

Detect any foreign objects, like debris or insects, inside packaging during production. This safeguards product quality and consumer safety.

Product counting

Accurately count products on a conveyor belt or in a storage area, eliminating manual counting errors and streamlining inventory management.

Tamper detection

Identify signs of tampering on packaging, such as tears, punctures, or resealing marks. This helps prevent compromised products from reaching consumers.

Thermal seal inspection

Detect inconsistencies in heat seals on food packaging. This ensures proper sealing and extends product shelf life.

Computer vision allows fast and precise medical images analysis. It helps in diagnostics and improved patient care. AI for cancer detection allows in healthcare professionals to detect malignancies early, leading to better treatment. Machine vision for healthcare offers doctors data-driven insights, making treatments more efficient and decision-making easier. It helps in the following ways:

Constant monitoring and maintenance make the best use of remote assets. Factors like outside force, corrosion, operator error, weld defects and aging trigger leaks in water, petroleum and process plants’ pipelines. CV continuously tracks flow rate, pressure and temperature for leak detection.

Tired of manual inspections missing subtle defects on your PCBs? Stop hidden defects from hindering your production. Our AI-powered computer vision solutions meticulously inspect PCBs, ensuring consistent quality and maximizing yield. Computer vision with AI could really help you with:

The best technique depends on your use case and accuracy needs. For fast, lightweight tasks, like counting items, traditional approaches like edge detection or Histogram of Oriented Gradients (HOG) work well. For high-accuracy tasks, like defect detection, deep learning methods offer better results. Traditional methods are faster and cost-efficient, while deep learning requires more infrastructure but handles complexity better. Many production systems use a hybrid approach for optimal performance.

Leading solutions for implementing computer vision in retail are those that improve store operations, reduce loss, and enhance customer experience. Key examples are automated checkout systems, shelf and inventory monitoring, planogram compliance, footfall and queue analytics, and video-based loss-prevention systems. These solutions help retailers maintain availability, boost conversion rates, and improve in-store efficiency.

Detection accuracy in supervised models improves through a combination of data quality, model design, and optimization strategies. High-quality labeled datasets, balanced classes, and strong data-augmentation practices help models generalize better. Using modern architectures, transfer learning, and optimized thresholds further sharpens final detection performance.

The best tools for implementing computer vision in quality control include OpenCV, TensorFlow, and PyTorch for model development. Industrial-grade platforms like Cognex, Keyence, and NVIDIA’s ecosystem support reliable deployment on the production line. These tools help automate defect detection, increase inspection speed, and ensure consistent product quality on the line.

Deep learning improves computer vision applications by learning complex patterns directly from large datasets, resulting in more accurate and adaptable models. Convolutional neural networks extract multi-level features that outperform traditional methods in classification, detection, and segmentation tasks. Architectures such as U-Net, ResNet, and Vision Transformers handle noise and variation better than classical methods, which leads to higher accuracy and stable performance in production environments.

Recent advancements in computer vision focus on deeper learning, faster inference, and broader real-world use. Vision Transformers improve accuracy across complex images. Edge vision enables real-time analysis on devices. Multimodal models combine vision with text and data, which improves contextual understanding and decision-making.

The primary benefits businesses gain from implementing computer vision include automation, accuracy, and scalability. Computer vision replaces manual inspections with automated visual analysis, improving quality control and safety. It also enables real-time insights from images and videos, helping organizations optimize operations and make faster, data-driven decisions.

Ethical concerns with facial recognition technology include privacy, bias, and misuse of personal data. Facial recognition can enable surveillance without consent. Bias in training data may lead to unfair outcomes. Responsible use requires transparency, strong governance, and compliance with data protection regulations.

Leverage our custom-built computer vision solutions and services to optimize business insights.

Computer vision is among the promising AI segments and we hold the expertise to extrapolate real-time data from images and videos.