If a label is wrong, the product, the shipment, and the brand pay the price. On high-speed lines, manual label inspection cannot match the pace or consistency required for packaging label quality control. Human eyes process around 10–12 images per second. On the other hand, an automated inspection system powered by machine vision and computer vision can process thousands of images per second.

Thus, it can deliver real-time defect detection across every pack, catching misprints, missing allergens, skewed barcodes, and unreadable date codes. The result is inline quality control that protects compliance and delivery schedules while keeping throughput intact.

In 2024, 45.5% of U.S. food recalls were caused by label errors, costing an estimated $1.92B. – New Food Magazine

That recall risk is why teams replace subjective checks with AI-based verification aligned to FDA label requirements and GS1 barcode standards. An experienced AI defect detection service provider can design sensors, lighting, and models, and integrate with PLCs and MES, and validate results against production targets that meet your requirements.

In this blog post, we will explore the capabilities of AI-powered label inspection and highlight common failure modes and costs, and outline rollout steps with reference architecture. We will also discuss its use cases in major industries where precise label inspection matters most.

What is AI-powered label inspection?

AI-powered label inspection is a process that uses calibrated cameras, controlled lighting, and trained vision models to check every label for content accuracy and print quality in real time. An AI-powered label inspection system captures each frame at line speed, locates the label, and runs a sequenced toolchain:

- OCR to read printed text

- OCV to confirm expected characters

- Barcode decode with ANSI/ISO grading

- Data verification against SKU, lot, expiry, and GS1 barcode standards

The result is inline quality control and real-time defect detection, with a clear pass or fail signal that can trigger an automatic reject.

Ther are two functions that work together here. An AI label verification system confirms the printed data is correct and machine readable. A machine vision label inspection system assesses how it is printed, including alignment, contrast, smears, voids, and skew. AI models learn normal variation across printers and materials, which stabilizes performance across shifts and SKUs and reduces false rejects. Architecture patterns and model choices for AI vision systems for packaging lines are addressed under industrial computer vision for packaging lines.

Types of label inspection defects and how to detect them

Label defects fall into four groups: placement errors, incorrect or unreadable content, print-quality issues, and security gaps. Each requires a defined inspection technique. Mapping each defect to the right method ensures issues are detected and corrected at line speed. Each defect below is paired with the method used to detect it.

-

Positioning and orientation

Pattern matching and edge detection locate the label, measure rotation, and flag skew before it advances. This step keeps placement consistent across shifts and materials by measuring rotation and offset on every unit.

-

Text and codes (dates and lots)

OCR reads the string, OCV checks it against the expected format, and rules confirm lot number and expiry date verification. AI models adapt to font and substrate changes, which reduces false rejects.

-

Barcode and QR quality

Decoding with ISO/ANSI grading validates print quality as well as readability. Tools grade to ISO/IEC 15416 for 1D and ISO/IEC 15415 and QR Code ISO/IEC 18004 for 2D, which catches incorrect barcode encodings early.

-

Print defects

Blob analysis and contrast checks detect smudged print, pinholes, banding, and faded ink. Adaptive thresholds maintain accuracy when ink density or carton tone changes.

-

Color and brand compliance

Delta-E targets compare measured color to approved references for brand panels and warning labels. Defined color tolerances hold brand targets across printers and suppliers.

-

Missing label detection

Presence sensors and region-of-interest checks confirm the label is present at the expected location. Partial peels and missing labels are treated as defects and automatically diverted off the line.

-

Tamper-evident features

Seal and perforation checks use edge profiles and template matching to verify security elements. Any break or misapplication triggers a fail decision.

-

Variable data label inspection

Schema rules validate GS1 AIs, serials, and batch fields against master data. This combines barcode and text inspection with AI to block labels that look correct but carry the wrong data.

-

Alignment and placement

Virtual calipers measure top, bottom, and lateral offsets to features or cutouts. Misalignment outside tolerance triggers a reject or line stop, depending on policy.

-

Multi-language OCR

Models tuned for Latin, Cyrillic, Arabic, and Asian scripts support global SKUs. Language-aware dictionaries improve recognition on small fonts.

Together, these methods deliver inline label defect detection that covers appearance and data integrity. For frequent changeovers, variable data label inspection maintains accuracy as SKUs, languages, and formats change.

Benefits of automating label and code inspection

Automating label inspection turns QC from an end-of-line check into inline quality control that protects compliance and margin. AI-powered print inspection software verifies content and print quality at line speed, so real-time defect detection stops defective units before they move downstream.

-

Fewer recalls and chargebacks

Data verification blocks wrong SKUs, lots, or allergens from reaching customers. Label issues drove 45.5% of U.S. food recalls in 2024, and the average direct cost per recall is about $10M, so preventing mislabeled units from reaching customers lowers financial risk.

-

Reduced scrap and rework

Catching issues at the station prevents further processing on defective units and improves first-pass yield. Field deployments report nearly 30% defect-rate reduction after AI vision is added.

-

Higher throughput and faster product switches

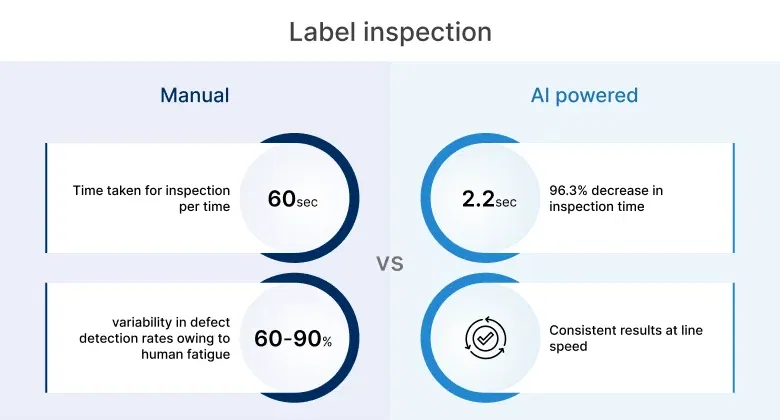

Inspection profiles update automatically when the SKU changes, keeping checks aligned without slowing the line. Documented results include a 27X inspection-speed gain – from 60 seconds to 2.2 seconds – and 6X output with 1/4th the amount of manual inspection labor.

-

Audit-ready compliance and traceability

The system logs every read, grade, decision, and timestamp for FDA and ISO reviews. This helps prevent common failure modes such as undeclared allergens, which accounted for ~84% of label-related food recalls in a 2024 analysis.

-

Stronger data verification

OCR, OCV, and code grading validate text, 1D, and 2D symbols against master data and GS1 rules. Because labeling mistakes are a leading recall driver in food and pharma, closing this gap reduces recall risk.

-

Digital label inspection analytics

Dashboards show top defect types by line, shift, and supplier. Teams act on the data to remove root causes and keep results steady across SKUs and substrates.

-

Labor efficiency and safer work

One operator can supervise multiple cameras instead of manual checks at high speed. Deployments report up to 75% less manual inspection, and a typical QC inspector salary near $89,000 per year highlights the labor impact.

-

Lower total Cost of Quality (COQ)

Fewer shipped errors, reduced scrap, and less rework lower the total cost of quality. Case studies show up to a 30× reduction in inspection costs and payback in under two years from efficiency and defect-reduction gains.

-

Scalable across lines and SKUs

Models learn normal variation across printers and materials, which keeps accuracy stable across shifts and SKUs and reduces false rejects. This makes it easier to roll out the same checks to new products and sites.

How to automate label quality checks and defect detection

To automate label inspection at scale, plan it as an engineered quality program that integrates industrial label inspection equipment, print quality inspection solutions, and production controls. This sequence shows how computer vision moves from clear standards to reliable daily operation.

Source: Assembly Magazine

-

Define critical-to-quality items and standards

List what must be correct: SKU text, lot number check, expiry date verification, barcode grading to ISO/IEC 15416 and 15415, color tolerance targets, and placement limits. Then, set acceptance limits, reject rules, and sampling so results are objective and auditable.

-

Select optics and lighting for the target features

Choose lenses that provide the field of view and pixel resolution to resolve the smallest character, code module, or print defect. You can match lighting to the substrate and finish, for example ring or dome for glossy stock, coaxial for reflective inks, backlight for edges, and use polarizers to control glare.

-

Choose the inspection tool stack

Pick an automated inspection system that supports OCR, OCV, 1D and 2D code grading, and rule-based print checks, then add AI models where classical tools struggle with warped text or variable substrates. Confirm the stack meets line speed and integrates cleanly with PLC or SCADA.

-

Build golden masters and a defect library

Capture approved labels and real nonconformities such as smears, voids, skew, wrong lots, unreadable codes, and low contrast. Use this dataset to train models, tune thresholds, and lock baselines before pilots move to production.

-

Integrate PLC reject and hold logic

Connect pass or fail to the PLC to actuate air knives, diverters, holds, or controlled stops. Add confirmation sensors and short buffers so rejected units are removed reliably without affecting throughput.

-

Deploy Statistical Process Control (SPC) dashboards and alerts

Log every read, grade, and decision with timestamps and shift or line context. Trend defect types and trigger alerts when rates cross control limits so teams intervene before issues accumulate.

-

Manage versions and change control

Maintain versioned inspection profiles per SKU with regions of interest, expected strings, barcode types, and tolerances. Require approvals, record release notes, and distribute centrally so stations remain consistent after updates.

-

Test on line, then prove at full production

Run challenge tests with seeded defects, verify false-reject and false-accept rates, and confirm first-pass yield meets targets. When the metrics are in range, increase to full speed and roll the setup to additional lines.

-

Optimize with production data

Review weekly trends to refine thresholds, retrain models as materials or printers change, and adjust lighting as equipment ages. Use these computer vision insights with suppliers and operations to remove root causes and sustain performance.

Technology and framework for label defect detection and inspection

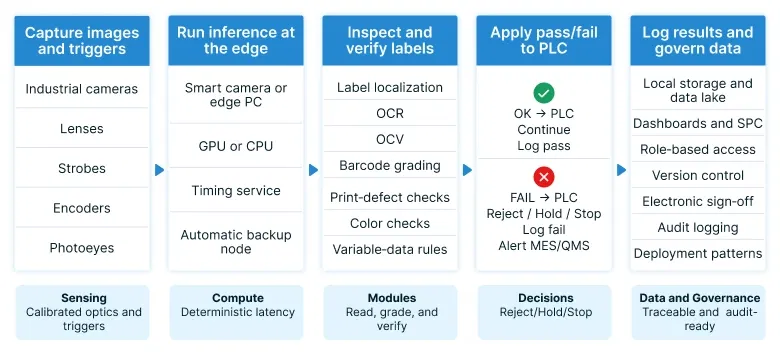

A robust label inspection architecture aligns optics, timing, inference, and plant controls so checks run at line speed. The stack combines a machine vision label inspection system with rule-based vision tools and deep learning for computer vision to read, grade, and verify data, then log every result for audit and improvement. This is the baseline for AI vision systems for packaging lines that require consistent, real-time defect detection.

- Cameras and strobes

- Encoder triggers and timing

- Inference node (DL + rules)

- Barcode grading

- OCR and OCV

- Data verification

- Reject logic and PLC integration

- Analytics store

- Dashboards and SPC

- Security and change control

- Deployment choices

Industrial area or line-scan cameras with the right lens capture full label fields, while strobes provide even, repeatable lighting that manages glare and shadows.

Line encoders or photoeyes issue hardware triggers so each frame is acquired at a precise position. Deterministic timing keeps inspections in sync with conveyor speed.

A smart camera or edge PC runs trained models and rule tools together. Choose GPU for higher throughput or CPU for lighter loads, and target stable latency with a backup node that takes over automatically.

1D and 2D symbols are decoded and graded to ISO/IEC 15416, ISO/IEC 15415, and ANSI barcode standards. Low contrast, quiet-zone issues, or damage are flagged before shipment.

OCR reads dates, lots, and text across fonts and substrates. OCV confirms expected characters and placements so copy errors are caught early.

Decoded fields are matched to the order master or MES record, including GS1 application identifiers. Any mismatch triggers a fail with an image and payload saved to the log.

Pass or fail signals drive the PLC to actuate an air jet or diverter at the correct offset. If communications fail or the node reports a health issue, the system pauses or diverts products to a safe state.

Results, images, grades, and timestamps are stored in a local repository and a central data lake with retention and access controls. This creates a traceable history for compliance and root-cause work.

Quality dashboards report first-pass yield, defect Pareto, and trend alerts. Teams review shifts and SKUs to refine settings and prevent repeat issues.

Role-based profiles, versioned inspection profiles, and electronic sign-off protect configurations. All changes are recorded with user and timestamp, which simplifies audits.

Single-node systems suit one line. Multi-camera cells feed a shared edge server for higher volumes, with mirrored nodes for failover and low-latency processing close to the line.

Industry-specific label inspection use cases

There are many label inspection use cases across regulated industries. The goal is consistent product label compliance inspection with accurate data verification, barcode grading, and clear print quality. The examples below show what to check and which standards apply, so teams can prevent recalls while keeping throughput high.

-

Healthcare

In healthcare, labels must communicate identity, dosage, and traceability without ambiguity because regulators audit every lot, and patient safety depends on it.

-

Pharmaceuticals

-

Medical devices

Multiple strengths often share artwork, which raises the risk of carton–vial mix-ups. Vision reads Global Trade Item Number (GTIN), lot, and expiry, grades 1D/2D codes to ISO/IEC 15416/15415, and matches claims text to the master and GS1 rules. The line packs the correct SKU and each batch leaves with proof images and logs for FDA and EMA reviews.

Pouches and trays must carry a durable Unique Device Identification (UDI) and required symbols. Inspection verifies DI and PI fields, checks MDR and FDA symbols and print contrast on curved films, and stores evidence by lot. Devices ship with traceable labels that pass audits and survive handling.

-

-

FMCG

Frequent changeovers and many variants in FMCG raise misprint risk, and consistent checks protect brand standards and retailer compliance.

-

Food and beverage

-

Cosmetics and personal care

Frequent changeovers increase the chance of a wrong allergen or a stale date. OCR and OCV confirm allergens, nutrition panels, lot, and expiry, while barcode and QR grades meet GS1 targets for scan quality. Lines run at speed with fewer relabels and cleaner tracebacks, which is critical on high-mix packaging lines.

Shade or variant mislabels create returns and chargebacks. Color and layout checks hold brand targets, while OCR confirms International Nomenclature of Cosmetic Ingredients (INCI) lists, batch codes, and period-after-opening symbols. Shelves stay consistent and retailers receive scan-ready units.

-

-

Electronics

Electronics require dense data and small codes to remain readable from assembly through service to preserve genealogy, warranty, and safety records.

-

Semiconductors

-

Consumer electronics and devices

A misread DataMatrix or the wrong moisture-sensitivity level can halt your SMT line. You validate lot and date codes, confirm Moisture Sensitivity Level (MSL) icons, grade barcodes to ANSI/ISO, and verify caution markings on reels and trays in one pass. With these checks in place, feeders set up correctly and genealogy stays intact.

Wrong region labels or serials break activation and warranty flows. The system verifies serial, IMEI or MAC against the build record and confirms regional text and power marks. Orders ship right the first time, and support teams see fewer units arriving non-functional.

-

-

Automotive

Automotive programs follow strict customer and regulatory label formats from inbound parts to finished vehicles, so verifiable compliance is required at each step.

-

Auto parts suppliers

-

OEM vehicle assembly

When an AIAG shipping label is hard to scan, receiving slows and fines follow. You grade AIAG formats on cases and pallets, verify part, lot, and date, and validate customer fields before ship. As a result, you hit on-time receipts and reduce chargebacks.

VIN, emissions, and safety labels must remain readable for years. Vision checks placement, text accuracy, and print contrast, then stores evidence by VIN. Vehicles clear end-of-line with a complete label record for service.

-

-

Logistics and warehousing

Logistics and warehousing rely on scan-ready Serial Shipping Container Code (SSCC) and accurate case-to-pallet mapping to maintain throughput and avoid ASN disputes.

-

Pallet traceability

Relabeling at docks slows loading and causes ASN disputes. Inspection verifies GS1-128 and SSCC, confirms case-to-pallet linkage, and grades codes before ship. Loads scan on arrival and claims fall.

-

-

Retail and e-commerce

Retail and e-commerce control order accuracy and returns cost through correct variants and scannable labels at pick, pack, and ship.

-

Order accuracy

Size and color mistakes create avoidable returns. The system validates UPC or EAN, marketplace IDs, and variant text against the pick list and packing slip. Customers receive the right item and return rates drop.

-

-

Chemicals and hazardous goods

Chemicals and hazardous goods need clear, durable hazard information to meet transport rules and workplace safety standards.

-

GHS compliance

Missing pictograms or H and P statements risk penalties and unsafe handling. Vision confirms pictograms, UN numbers, signal words, and supplier details on chemical-resistant media. Shipments meet GHS requirements and teams handle containers safely.

-

-

Agriculture

Agriculture maintains seed identity and field to fork traceability with precise variable data that survives handling across the supply chain.

-

Seed packaging

-

Fresh produce and cold chain

Wrong variety or missing treatment markers cause costly claims. Inspection verifies variety, lot, treatment icons, and germination date, then grades GS1 barcodes for case and pallet. Distributors and growers receive correctly identified seed.

Recalls demand exact origin and pack details. The line checks Produce Traceability Initiative (PTI) fields, GS1 DataBar or QR, country of origin, and pack date at speed. Retailers can trace lots quickly without relabeling.

-

Standardize label inspection with AI accuracy

Modern label inspection removes the two risks manual checks cannot: speed limits and human variability. Mislabels drive costly recalls and chargebacks, while line speeds outpace what a human can reliably verify. AI-powered label inspection delivers real-time defect detection, inline quality control, and consistent data verification against FDA and GS1 requirements, so every unit meets compliance.

If you are dealing with frequent changeovers, variable substrates, or recurring barcode and expiry errors, a professional implementation team can calibrate optics, train models, and connect results to your PLC and QA systems. You will gain audit-ready logs, stable first-pass yield, and fewer stops for rework. Connect with an experienced AI defect detection partner to assess one packaging line, define the inspection rules and optics, and outline a phased rollout that meets your standards and budget.

FAQs

1. What is an AI-powered label inspection system and how does it work?

An AI-powered label inspection system is a machine vision setup that checks every label for content accuracy and print quality in real time. It uses cameras and controlled lighting to capture images, then applies OCR to read text, OCV to confirm expected characters, barcode grading to ANSI/ISO, and data verification against master data such as SKU, lot, expiry, and GS1 rules. The system issues pass or fail results and signals the line to reject nonconforming items.

2. What is the difference between label verification and label inspection?

Label verification is the process that confirms the printed data is correct and machine-readable, such as the right lot number, expiry date, or barcode content and grade. Label inspection is the process that checks how the information is printed, including alignment, contrast, smears, voids, skew, color consistency, and presence. Both work together to ensure compliant, readable, and high-quality labels.

3. Is it possible to integrate AI label inspection into existing production lines?

Yes, it is possible to integrate AI label inspection into existing production lines by selecting cameras, lenses, and lighting that fit current conveyors and by connecting triggers, encoders, and reject mechanisms to the PLC. Most systems run at the edge with low latency and share results to Manufacturing Execution System (MES), Quality Management System (QMS), or data warehouses for reporting and audits.

4. Why does label inspection matter across different industries?

Label inspection matters across industries because labels carry identity, safety, and regulatory information that must be correct and readable. Food, pharma, medical devices, chemicals, and consumer goods all rely on accurate text and barcodes to prevent recalls, meet standards, and guide safe use.

5. What are the most common labeling challenges in various sectors?

The most common labeling challenges are misprints and smears, incorrect or missing variable data, low barcode grades, wrong artwork versions, misplacement or skew, and unreadable dates. Regulated sectors also face strict rules on allergens, ingredients, dosage, warnings, and traceability, which require consistent verification on every unit.

6. How does AI-powered label quality inspection work in any production environment?

AI-powered label quality inspection works by combining trained models with rule-based tools so the system adapts to printer variation, materials, and lighting. The models detect label regions and defects, while OCR, OCV, and barcode graders provide structured checks that align with standards, giving reliable results across lines and shifts.

7. What are label check vision inspection systems and how do they ensure accuracy and compliance?

Label check vision inspection systems are computer vision solutions that read and grade codes, verify text, and assess print quality at line speed. They ensure accuracy and compliance by comparing live reads to master data, applying ISO/IEC barcode grading, logging results for audits, and triggering rejects when a unit falls outside defined limits.

8. How can businesses automate label and code inspection at scale?

Businesses can automate label and code inspection at scale by standardizing critical-to-quality criteria, selecting optics and lighting for each package size, and deploying a repeatable toolset that covers OCR, OCV, barcode grading, and print-quality checks. They should connect results to PLC reject logic, stream data to SPC dashboards, and manage change control so recipes, tolerances, and artwork versions stay current.

Talk to us to find out how a phased rollout plan can start on one pilot line, prove ROI, and scale across plants with shared models and governance.

9. Why is label inspection and verification important for packaging operations?

Label inspection and verification are important for packaging operations because they prevent mislabels from reaching customers, reduce rework, and support on-time shipping. They also create traceable, audit-ready records that help teams answer compliance questions quickly.

10. How does a label inspection system improve print quality and data verification?

A label inspection system improves print quality by measuring contrast, defects, and alignment and by rejecting units that fall below defined thresholds. It improves data verification by reading text and codes, comparing them to the production order, and grading barcodes to ISO/ANSI so every unit is both correct and scannable.

11. What business benefits does label inspection provide beyond quality control?

Label inspection provides benefits beyond quality control by reducing recalls and chargebacks, cutting scrap and rework, and improving first-pass yield. It also speeds changeovers with recipe control and gives operations reliable data for continuous improvement and customer audits.