Customer background

Our client is a chip manufacturer with facilities across the globe. Headquartered in the United States of America, they provide chips and other semiconductor devices to 1500+ companies including OEMs, electronics manufacturers, and distributors, located in 10+ countries. Their products are used in consumer automotive systems, consumer electronics, and telecommunication.

Challenges

Semiconductors chips are used in all electronic devices, from smartphones and televisions to automobiles. Therefore, accuracy in its inspection is important and critical.

Our client wanted massive improvement in their fab performance and had higher goals. Therefore, they wanted to solve inspection challenges—both from a business and an operational standpoint. Let’s take a look.

Business challenges

- Quality assurance at scale: The client faced difficulties in maintaining consistent chip quality while scaling production. As product complexity increased, the need for more advanced quality control methods became essential.

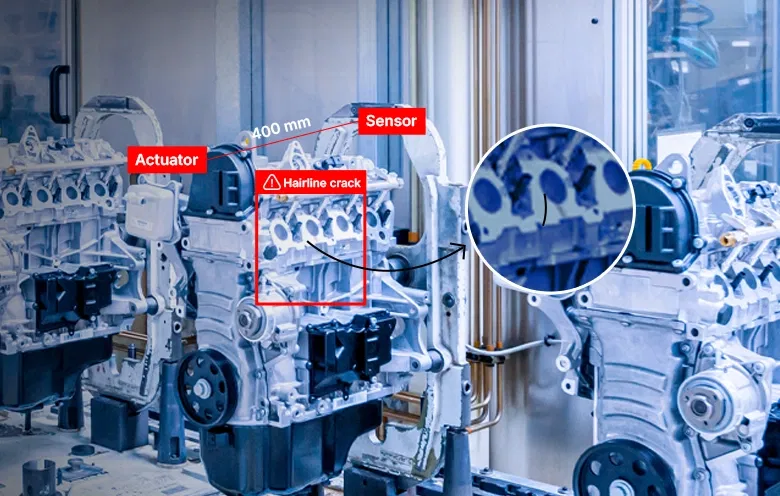

- Defect management: Defects identified late in the process—or after deployment—could lead to expensive rework, warranty claims, and potential damage to brand reputation. They could include scratches, cracks, peeling, missing components, and edge defects.

- Innovation pressure: The client needed to continuously improve and innovate inspection technologies to stay competitive in their market.

Operational challenges

- Inefficiencies in manual inspection: Manual inspection processes were time-consuming, labor-intensive, and lacked the precision needed to detect micro-level defects consistently.

- Limitations of traditional machine vision: Rule-based vision systems were unable to accurately detect the increasing range and complexity of defects, especially as integrated circuits became smaller and more intricate.

- Layer-by-layer complexity: Each wafer layer required individual inspection, and undetected defects at early stages often led to compounding failures in subsequent layers.

- Data labeling bottlenecks: Supervised deep learning requires large volumes of accurately labeled images, which was a time-intensive and laborious process.

Our solution

Our team of AI developers worked closely with the client to understand their inspection workflow and identify root causes of recurring issues.

We proposed an AI-driven solution integrating machine learning, deep learning, and computer vision to enhance defect detection accuracy, automate the inspection process, and significantly reduce reliance on manual reviews.

Data collection and preprocessing from chip manufacturing processes

In this first phase, we gathered and preprocessed various types of data from semiconductor manufacturing processes systematically.

- Types of data collected: The data includes defect logs, production parameters, equipment performance metrics, environmental situations, and maintenance history.

- Data sources and preprocessing: Here, we collected data from diverse sources including sensors, production databases, and historical maintenance logs.

Application of AI and deep learning techniques for predictive analytics

In this phase, we outlined the specific AI techniques and their basis for use in predictive analytics within semiconductor manufacturing.

- Overview of algorithms: We utilized a variety of machine learning and deep learning algorithms such as decision trees, random forests, support vector machines, Convolutional Neural Networks (CNNs), and Recurrent Neural Networks (RNNs).

- Purpose of using AI techniques: Our team of AI experts utilized machine learning as its algorithms had the capability to handle large, complex datasets and find complex patterns. Deep learning models like CNNs and RNNs perform remarkably where image recognition was required to detect defects, and sequential data analysis was imperative for predictive maintenance.

Predictive model development and evaluation using deep learning frameworks

Then, we developed predictive models and trained, validated, and tested them.

- Model development process: We used frameworks like TensorFlow and PyTorch to build the models. We began by defining model architectures, followed by selecting appropriate loss functions, and finally used optimization algorithms to train them.

- Training, validation, and testing: We split data into three sets: training, validation, and testing to ensure the models generalize well. Then, we employed cross-validation techniques to fine-tune hyperparameters and avoid overfitting.

AI model implementation and integration into workflows

In the final phase, we focused on the practical steps required to integrate AI models into semiconductor manufacturing workflows.

- Integration steps: We deployed AI models within existing manufacturing systems. This included real-time data ingestion, model inference, and integration with control systems for automated decision making.

- Tools and platforms: We used tools like Python for scripting, and cloud-based platforms for scalable deployment.

-

Industry

-

Technologies / Platforms / Frameworks

AI, ML, Deep learning, TensorFlow, PyTorch, and Python

-

Benefits

- Improved accuracy: Our deep learning models enhanced defect detection and quality control for our client’s fab performance.

- Reduced development times: Our solution automated the complex tasks and streamlined chip production times.

- Increased revenue: Our client enhanced production processes which resulted in higher efficiency, profitability, and revenue.

Decades of Trust & Experience

1630+

Projects

545+

Experts

26+

Products and Solutions

1020+

Customers

Similar Case Studies

Consolidated acquired product catalogs into a unified PIM for a global semiconductor leader

Enhanced quality control system for a manufacturing company with machine learning

Automatic defect detection on semiconductor wafer surfaces using deep learning

Connect Now

Our experts would be eager to hear you.