Client profile

Our client is a US-based machine manufacturing company with multiple production facilities across the globe. They specialize in producing industrial machinery and replacement parts for sectors such as construction, logistics, and heavy engineering. Operating across multiple regions, they manage a vast network of customers and vendors, many of whom transact on credit terms requiring efficient coordination and operational agility.

Technical challenges

For years, the client relied on traditional, manual quality inspection systems. While these systems were effective in the past, they struggled to keep pace with the growing need for speed, precision, and scalability. Several pressing issues surfaced:

- Traditional quality control systems: They lacked automated inspection processes, making it difficult to detect quality issues in real time.

- High production waste and rework costs: Defects were identified too late in the cycle, leading to unnecessary waste and increased costs.

- Operational inefficiencies: Their processes were slow and manually intensive, causing delays and reduced throughput.

- Global competition and market volatility: They lacked the ability to respond to fast-changing market conditions and technological advancements.

- Data overload: They did not have a system to manage or analyze the growing volume of quality and safety data effectively.

- Delayed responses: There was no mechanism to alert teams in real-time, leading to slower incident response.

- Integration complexity: They struggled to connect legacy systems with modern safety and quality tools.

- Connectivity issues: Network disruptions affected their ability to perform real-time monitoring across production lines.

- User adoption: Field teams were not equipped or trained to fully utilize digital solutions.

Our solution

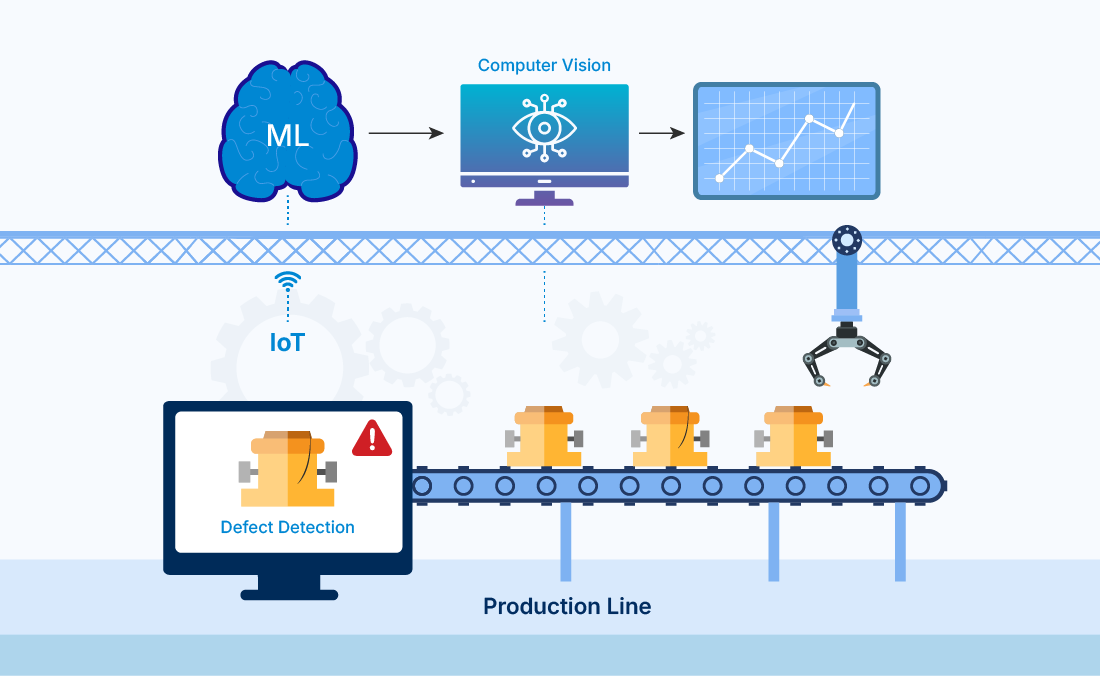

To resolve the client’s ongoing challenges, we developed and implemented an end-to-end solution rooted in AI, machine learning, and IoT technologies. The aim was to create a smart, scalable infrastructure that modernizes how the client manages quality control, safety, and operational efficiency across all production facilities. Our solution transformed not only their data systems but also empowered their workforce to act faster and more accurately. By modernizing their systems and workflows, we helped the client detect and prevent quality defects early, reduce waste, and improve safety compliance. This implementation also allowed seamless integration across platforms and provided stakeholders with real-time access to business-critical insights.

Key capabilities provided include:

- Defect detection: Integrated cameras and AI models using computer vision to inspect products in real-time, flagging defects instantly.

- Predictive maintenance: Machine learning algorithms predict equipment failures and notify teams ahead of time.

- Automated data pipelines: Data is collected, staged, transformed, and made analytics-ready without manual intervention.

- Smart safety compliance monitoring: Used AI and sensors to automatically identify safety hazards like missing PPE, unsafe motion paths, and alert supervisors in real time.

- Energy optimization: Deployed IoT sensors to monitor energy consumption and recommended load balancing and peak-hour adjustments to reduce energy costs.

- Sensor-integrated production line monitoring: Installed IoT sensors across key production nodes to continuously track temperature, vibration, load, and speed, providing live equipment health metrics to operational teams.

-

Industry

-

Technologies / Platforms / Frameworks

AI, Machine learning, Computer vision, IoT platforms

-

Benefits

- Reduction in production waste: Early-stage defect detection led to a measurable drop in rework and material loss.

- Stronger safety compliance framework: Real-time visibility helped teams stay ahead of violations.

- Improved incident response times: Enhanced monitoring allowed faster reaction to on-floor incidents.

- Insight-driven operations: Unified data allowed leadership to act on trends and hidden inefficiencies.

- Higher productivity through automation: Manual steps were eliminated with automation, minimizing delays and errors.

- Elevated workforce protection: IoT and sensors ensured more accurate tracking of people and asset.

Decades of Trust & Experience

1630+

Projects

545+

Technocrats

26+

Products and Solutions

1020+

Customers

Similar Case Studies

Consolidated acquired product catalogs into a unified PIM for a global semiconductor leader

Automatic defect detection on semiconductor wafer surfaces using deep learning

Streamlined invoice reminder processes with RPA for a leading manufacturing company

Connect Now

Our experts would be eager to hear you.