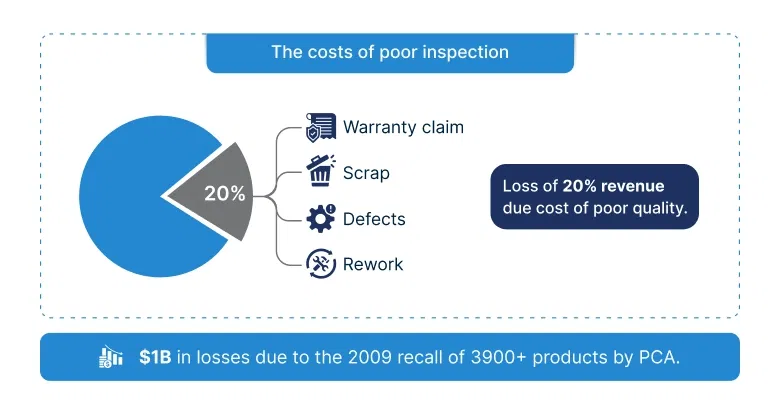

Defects that pass inspection end up costing you. From missed defects that disrupt production to recalls that weaken customer trust, companies need to hold a near-zero-defect bar while scaling output.

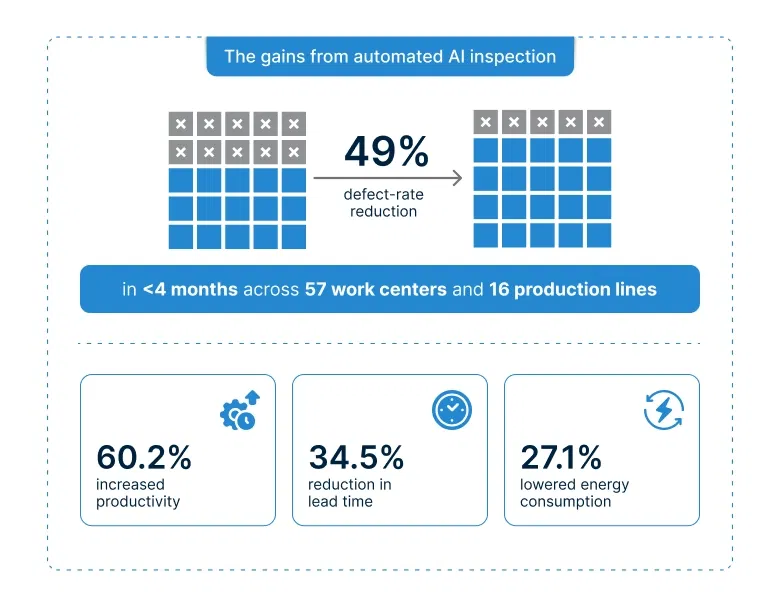

Deloitte reports that AI-driven quality control can cut defect rates by up to 90%, turning inspection into a reliable way to increase yield and strengthen customer trust.

That potential is why leaders across manufacturing, pharma, food, automotive, and semiconductors are rethinking inspection. Automation and AI offer not only consistency but also measurable financial relief. Professional solution providers design AI defect detection visual inspection systems that accelerate quality checks, improve compliance, and give teams confidence that every unit meets the required specifications.

This blog post will explain what automated visual inspection is, the technologies that make it possible, industry use cases, benefits, and future trends shaping next-generation inspection strategies.

What is automated visual inspection?

Automated visual inspection is a real-time quality process that uses cameras, lighting, and AI to detect defects as products move through the line. It replaces variable manual checks with consistent, data-backed decisions and creates a traceable record for every unit. A modern visual inspection system reduces missed defects, stabilizes throughput, and gives teams the confidence to scale.

How does automated visual inspection work?

From image capture to automated action, here is how a visual inspection system operates on the line.

-

Image capture

Cameras, lenses, and lighting are matched to part material and line speed to produce repeatable frames. Triggers and encoders lock exposure to position so each required feature is in view without blur.

-

Image analysis

Captured frames run through computer vision that normalizes brightness, enhances contrast, and isolates regions of interest. Trained models then classify surface flaws, dimensional drift, and assembly errors, returning precise scores and locations.

-

Quality response

Model scores and rule thresholds produce a pass/fail decision aligned to risk and spec. That decision drives ejectors, diverters, or safe stops immediately, while operators receive targeted alerts.

-

Process feedback

Results and images post to MES/SPC to track yield, false rejects, and drift. Teams adjust thresholds and upstream steps, and curate new examples to keep models accurate over time.

With an automated visual inspection system in place, you get consistent outcomes at speed and audit-ready traceability.

Key components of an automated visual inspection system

Choosing the right building blocks de-risks deployment and keeps decisions consistent at line speed. Modern automated visual inspection systems combine precise imaging, smart software, and clean integration so quality scales predictably. Use these components as your checklist when evaluating a vision system for quality inspection.

-

Imaging hardware

An automated inspection camera, the right sensor, lens, and standoff capture crisp features at your line speed. Stable mounts and enclosures protect alignment so images remain repeatable across shifts.

-

Lighting and optics

Diffuse, coaxial, backlight, or structured light exposes contrast where defects hide. Matched optics control glare and depth of field so the vision stack sees the same truth every cycle.

-

Part presentation and motion

Conveyors, fixtures, or robots present each feature to the camera at a consistent angle and gap. Encoders, photo-eyes, and strobes synchronize capture to motion to avoid blur.

-

Computer vision and deep learning

Classical CV handles geometry and measurement; deep learning classifies hard-to-code defect patterns. Versioned models and recipes keep outcomes stable through product changeovers.

-

HMI, UI, and reporting

Operators set tolerances, review images, and manage changeovers through a clear interface. Built-in reporting shortens investigations and gives teams immediate visibility into rejects and trends.

-

Integration: PLC, MES, ERP

PLC I/O links pass/fail outcomes to ejectors, diverters, and safe stops. APIs feed MES, SPC, and ERP with images and metadata for traceability, compliance, and closed-loop improvement.

Need a clear plan for your automated visual inspection pilot?

Core technologies behind automated visual inspection

High-confidence inspection comes from how you combine methods, where you run them, and how you keep them current. The right automated visual inspection AI stack lifts detection, reduces false rejects, speeds changeovers, and leaves a clean audit trail that stands up in regulated environments. Here’s the stack that delivers those outcomes at production rate.

-

Traditional CV vs deep learning

Classical CV excels at geometry, gauging, and alignment with fast, deterministic rules. Deep learning handles variable textures and subtle flaws; a hybrid approach keeps measurements stable as products and lots change.

-

Anomaly detection

When labeled defect images are scarce, models learn “normal” and flag departures in real time. Anomaly detection reduces labeling effort and surfaces new failure modes before they turn into trends.

-

3D vision and robotics

Depth cameras and laser profilers reveal height, flatness, and surface topography that 2D can miss. Robot-guided views hold pose and angle, improving cycle time and making each feature equally inspectable.

-

Edge and cloud

Inference runs at the edge for low-latency AI inspection; training, experiment tracking, and fleet analytics run in the cloud. Secure rollout and rollback keep updates safe across stations and sites.

-

Digital twins

Virtual cells let you test camera positions, lighting, and reject logic before hardware lands. Synthetic defect data accelerates model readiness and links inspection signals to upstream process tuning.

Good execution starts with operational discipline. To scale, you need dependable MLOps for data curation, versioning, deployment, and monitoring so each line runs the same trusted setup. Reliable automated inspection solutions bring both together, from pilot to plant-wide rollouts.

Business applications and industry use cases

Every industry faces distinct defect patterns, speeds, and compliance needs. The following use cases show how automated visual inspection delivers measurable outcomes, helping teams scope AI visual inspection for defect detection and plan automated quality inspection with confidence.

-

Electronics and semiconductors

Inline vision screens sub-micron defects that drive scrap and RMAs before value adds up. Linking images with SPC tightens process windows across tools and lots without slowing material handling. Saved inspection profiles control keeps outcomes stable through product and mask changes at high mix.

Yield impact: According to API4.ai, a leading fab reported a two-three percentage point yield increase and 50% fewer returns after deploying AI vision to catch micro-flaws before shipment.

-

Manufacturing

Mixed-model lines need fast, stable checks for surfaces, assemblies, and dimensions at cycle time. CAD-assisted gauging and golden images keep measurements consistent through changeovers. Cells scale from single-station pilots to multi-camera layouts without disrupting flow.

Precision gains: According to a Harvard Business School case study, Bridgestone achieved over 15% better quality precision with AI-based inspections, improving consistency across batches.

-

Pharma and food

Quality and compliance move together on these lines. Vision validates particulates, fill, closure integrity, seals, and GS1/label accuracy at production speed, then proves it with audit-ready records. IQ/OQ/PQ with challenge sets shortens investigations and supports faster release.

Risk and payoff: As found in a Gallup study, 53% of Americans say they’ve avoided buying certain brands or types of food because of a recall or advisory; AVI lowers this exposure by catching issues before goods ship.

-

Automotive

Safety and finish quality rely on repeatable checks for weld seams, adhesive beads, torque markers, and paint surfaces. Robot-guided views hold pose and lighting so small defects are visible at cycle time. Results tie to build records for traceability and faster root cause analysis.

Finish quality results: Painting lines using vision saw a 35% reduction in paint-related rework alongside higher first-pass yield and better finish quality.

-

Healthcare and medical devices

Small batches and tight tolerances demand 100% inspection with controlled access to records. High-mag imaging and UDI verification log evidence into the device history record to support ISO 13485 audits. Operator-assist cells handle exceptions without slowing release.

-

Consumer packaged goods

High-volume packaging needs speed and accuracy in lockstep. Vision verifies caps, seals, fills, and codes in sync with fillers and cappers, with reject confirmation to prevent re-entry. Variation libraries keep accuracy high across SKUs and artwork changes.

Line-speed results: As reported by Vision Systems Design, AI vision has sustained 1,200 cap inspections per minute (≈72,000/hour) on bottling lines and helps improve first-pass yield.

Top 6 benefits of automated inspection systems

The value of automated quality inspection shows up in stable quality, faster lines, and fewer surprises. Here’s how automated inspection delivers value and how to reduce implementation risk.

Sources: Reuters, McKinsey, World Economic Forum, KatanaMRP

-

Consistency and accuracy

AI removes shift-to-shift variability and applies the same criteria to every part. With a stable visual inspection system, teams spend less time debating borderline calls and first-pass yield stays steady across changeovers.

-

Throughput at quality

Edge inference keeps inspection off the critical path so lines run at cycle time without bottlenecks. Cells expand from single to multi-camera stations without lengthening cycle time because decision latency stays in milliseconds.

-

Scrap and rework reduction

Catching issues at the source cuts waste and shortens rework loops. A technical case published by API4.ai reported a 20% scrap reduction in textiles after deploying automated vision, with more consistent quality across batches.

-

Lower recall risk

Better detection upstream reduces downstream field failures and warranty exposure. As discussed at the Society of Automotive Analysts’ Recall Summit, WardsAuto reported 382 U.S. auto recalls in 2023 and about $10B in warranty and recall costs among leading OEMs, underscoring the value of preventing defects at the line.

-

Audit-ready data and compliance

Images and metadata create a traceable record for SPC, MES, and audits. In a published industry example, combining optical and X-ray checks delivered 25% less defect-related rework while meeting IEC and UL safety requirements.

-

ROI and payback

Plants often see payback inside a year as errors fall and labor redeploys. Food Industry Executive highlighted manufacturers achieving ROI within 12 months from AI vision through fewer errors, lower waste, and steadier staffing.

Implementation roadmap and validation

Use this step-by-step list to reduce adoption risk and keep your rollout on track. Tick each box before moving to the next stage.

-

Discovery and scoping

- Document parts, defect types, production rate, constraints, and business goals.

- Select the visual inspection method; shortlist types of automated inspection systems with rationale.

- Define success criteria and draft a data plan (what to collect, where, how often).

-

Data capture and labeling

- Capture image sets across variants, materials, and lighting conditions.

- Label defects using metrology measurements as ground truth.

- Establish dataset governance (balance, versioning, access, retention).

-

Proof of concept (off-line)

- Validate optics and lighting on the bench with sample parts.

- Set and meet targets for detection, false rejects, and decision time.

- Produce a baseline specification the line can run.

-

Pilot cell (at line speed)

- Integrate PLC/MES and HMI; test operator workflow.

- Validate inspection settings across changeovers.

- Monitor performance; record and approve adjustments.

-

Scale up

- Standardize cell design, wiring, and settings in a build pack.

- Implement MLOps for model/data versioning, rollout, monitoring, and feedback.

- Define the update process for stations and sites (owners, triggers, steps).

-

Acceptance criteria and Governance

- Define approval stages with owners and sign-off rules.

- Align KPIs: precision, recall, decision time, First Pass Yield (FPY), and Gage Repeatability & Reproducibility (GR&R).

- Agree on required documentation (change control, test records, reports).

-

Change management

- Train roles; update SOPs and work instructions.

- Set the communication schedule (standups, metric reviews, issue escalation).

- Define the support model (ownership, response times).

-

Validation (IQ/OQ/PQ)

- Complete Installation Qualification (IQ) with as-built records.

- Run Operational Qualification (OQ) with defined challenge sets.

- Pass Performance Qualification (PQ) at production rate with a full audit trail.

Plan a focused pilot

If a pilot is your next step, request a PoC scoping session to align parts, metrics, and timeline, and leave with a clear go or no-go plan.

Future trends in automated inspection

The next wave moves beyond “detect and reject” to “predict and prevent.” Expect AI visual inspection to fuse richer data, smarter automation, and stronger governance so quality improves continuously, not only at final inspection.

-

Synthetic defect data

Generative and physics-based engines will create rare, parameterized defect families with uncertainty labels, filling coverage gaps without halting production. Active learning will target the next best examples, while digital twins score “scenario coverage” before a model sees the line.

-

Multimodal sensors

Future cells will fuse vision with acoustics, vibration, and thermal streams so models catch precursors before defects are visible. Event cameras and hyperspectral options will join RGB feeds, with foundation models learning cross-sensor patterns for earlier, surer calls.

-

Edge-cloud orchestration

Model placement will become policy-driven: low-latency inference at the edge, with cloud bursts for retraining, drift analysis, and fleet A/B tests. Federated learning will share improvements across sites without moving sensitive data, keeping AI-based visual inspection automation compliant and current.

-

Autonomous cells

Self-calibrating optics and auto-tuned lighting will maintain image quality as parts and environments change. Robots will re-aim views on the fly, and closed loops will propose safe process corrections (with human approval), shifting inspection from a checkpoint to a source of continuous control.

Turn AI inspection into a quality, speed, and compliance advantage

Manual checks struggle to keep pace as products diversify and lines speed up. The result is variability at critical points, rising investigation effort, and pressure to prove compliance without slowing output. A well-tuned imaging setup delivers clear frames, and AI interprets them to issue consistent pass/fail decisions at line speed while maintaining accurate records for audits and root cause analysis.

Reduce adoption risk and move quickly, talk to an experienced automated visual inspection partner to design a small pilot with clear acceptance criteria. Scale with MLOps so every station runs the same trusted setup and quality becomes a measurable advantage.

FAQs

1. What is automated visual inspection?

Automated visual inspection is the use of cameras, lighting, computer vision, and AI to detect defects and verify features automatically as products move on the line. It replaces variable manual checks with consistent, data-backed decisions and creates a traceable record for every unit.

2. Which industries benefit the most from automated visual inspection?

Industries that benefit the most are electronics and semiconductors, automotive, pharmaceuticals and medical devices, food and beverage/CPG, and discrete manufacturing. These sectors run high volumes or tight tolerances where consistent, at-speed quality checks and audit trails are essential.

3. How is AI changing the future of visual inspection systems?

AI is changing visual inspection by learning subtle, variable defect patterns that rules alone miss and by enabling anomaly detection when labeled defects are scarce. It also supports faster model updates via MLOps and, increasingly, synthetic data and multimodal sensing for earlier, more reliable calls.

4. What challenges do companies face when implementing automated visual inspection?

Companies face challenges in getting stable imaging (lighting, lenses, part presentation), assembling quality datasets and labels, and integrating with PLC/MES at line speed. They also must manage change, define clear acceptance criteria, and maintain models over time to prevent drift.

5. Can automated visual inspection handle complex defects or only surface-level issues?

Automated visual inspection can handle both surface and complex defects when the imaging is designed appropriately. 3D profilers, X-ray/CT, thermal or hyperspectral sensors, and deep learning enable detection of dimensional errors, internal flaws, or material anomalies beyond simple surface checks. Talk to us about your use case and we’ll assess imaging options and feasibility.

6. What role does computer vision play in Industry 4.0 and smart factories?

Computer vision plays the role of a high-fidelity sensor for quality and traceability in smart factories. It feeds MES/SPC and digital twins with image evidence and metrics, enabling closed-loop adjustments that stabilize processes and reduce waste.

7. How cost-effective is automated visual inspection in the long run?

Automated visual inspection is cost-effective by lifting first-pass yield and cutting scrap, rework, and warranty exposure, while letting teams redeploy labor to higher-value tasks. A practical way to estimate value is to model fewer escapes and rework against cost of poor quality and line downtime.

8. Is automated visual inspection suitable for Small and Medium Businesses (SMBs)?

Automated visual inspection is suitable for SMBs when scoped as a focused pilot on a critical part or station. Modular hardware, edge inference, and managed model services let teams start small, prove value, and expand without heavy upfront complexity.

9. What are the techniques of machine vision in automated inspection?

The techniques of machine vision in automated inspection include lighting design and optics, image preprocessing and normalization, segmentation and region-of-interest extraction, feature measurement and gauging, template and pattern matching, edge/blob analysis, OCR/OCV, and 3D profiling. Deep learning adds classification, detection, and segmentation of complex defects, plus anomaly detection for “unknown” faults.