Automotive

Real-time inspection of paint, panels, engines, and parts to achieve zero-defect assembly.

Our Clients

Manual inspection struggles to keep pace with today’s high-speed production lines, allowing defects to go unnoticed. By pairing computer vision with machine learning, AI defect-detection solutions scan every frame in milliseconds, flag anomalies the instant they appear, and give operators immediate insight to intervene before problems spread, so that you can protect throughput and product quality.

Softweb Solutions is focused on using AI for defect detection into a practical shop-floor solution. We build custom inspection suites that integrate seamlessly with your workflow. Our team maps inspection points, tunes deep-learning models, and streams results to your existing systems used for scheduling and reporting. With our AI defect detection services, you gain instant visual proof of quality, and the data needed for faster, more confident decisions.

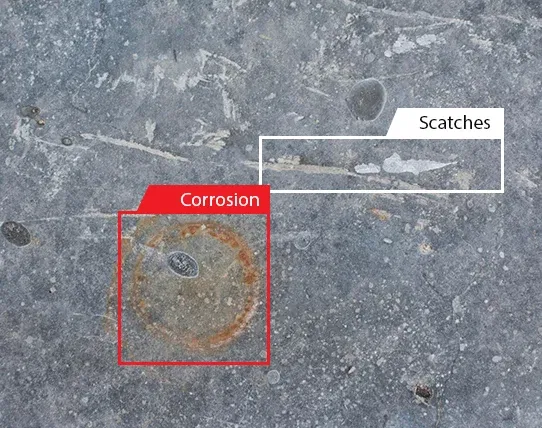

Surface scratches and corrosion

Surface defects include scratches, dents, corrosion, and discoloration that compromise appearance and sometimes performance by exposing materials to abrasion or rust. We apply high-resolution vision and texture analysis to spot even hairline marks early, so adjustments are made before parts move downstream.

Structural cracks and deformations

Structural anomalies such as cracks, holes, deformations, and missing components weaken product integrity and may cause failure under load. We use deep learning geometry models to detect breaks, voids, and shape deviations in real time, allowing teams to reject or repair parts before assembly continues.

Dimensional misalignments warping

Dimensional defects appear when parts are misaligned, warped, or made over or undersized, causing poor fit, leaks, or vibration. We capture calibrated images and apply subpixel measurements that flag out-of-tolerance dimensions instantly, so operators adjust tooling without stopping the line in real time.

Cosmetic paint smudges and stains

Cosmetic flaws such as paint drips, smudges, stains, and irregular finishes hurt brand perception even when function remains intact. We deploy color and texture analytics to detect subtle finish inconsistencies, alerting crews immediately so aesthetic standards stay high and costly rework is avoided.

Functional weld and solder defects

Functional defects arise from weak welds, poor solder joints, and loose connections that jeopardize product performance or safety. We combine thermal clues with vision AI to flag incomplete bonds and micro voids, so that your engineers can repair joints promptly and prevent downstream failures or costly recalls.

Contamination dust oil on surfaces

Contamination defects include dust, fibers, oil, or other foreign objects that cling to surfaces and cause blemishes, shorts, or hygiene risk. We apply high-contrast lighting and particle detection algorithms to spot contaminants in motion, triggering clean routines before affected units leave the line.

Labeling and packaging inaccuracies

Labeling and packaging errors like misprints, unreadable barcodes, or missing labels cause returns, compliance fines, and lost traceability. We use OCR and shape matching to verify text clarity, code accuracy, and label placement instantly, ensuring every package meets regulatory and customer rules.

Assembly misplacements loose joints

Assembly issues can arise when components are misplaced, oriented wrongly, or left loose, leading to failures and warranty claims. We track position, orientation, and torque using vision and sensor fusion, catching assembly errors instantly so teams can correct issues early without disrupting production schedules.

Contact our experts to implement AI defect detection and start reducing defects, cutting costs, and improving output.

Get started now

AI inspects every unit at line speed to move toward zero-defect production. These systems identify surface, dimensional, and assembly issues and feed trends back to process control for fewer downstream defects and less rework. Applications:

AI image analysis rapidly triages studies and identifies early signs of disease across X-ray, CT, and MRI. Beyond diagnostics, computer vision verifies instrument condition in sterile processing to reduce risk before procedures. Applications:

Vision AI combines thermal imagery with acoustic and ultrasonic readings to detect leaks and early corrosion in pipelines, tanks, and steam systems. This non-destructive approach reduces downtime and environmental risk while keeping crews out of hazardous zones. Applications:

High-resolution cameras and deep learning detect microscopic defects at production speed and feed clear pass/fail decisions to the line. Systems run before and after soldering, integrate with SPI and 3D imaging, and link to MES for hold and reject. Applications:

We apply real-time AI vision to scan every unit as it leaves the station, eliminating queues and freeing operators for higher-value tasks while throughput stays high.

Using AI-powered machine vision, we catch defects at the first touchpoint, preventing faulty parts from moving downstream and sharply reducing material waste.

We help you shorten release cycles by flagging quality issues the instant they appear, so your team can address root causes quickly and launch new products sooner.

Our centralized AI models enforce identical pass/fail rules across plants, shifts, and lines, removing human variability and delivering consistent product quality.

We apply automated image logging and decision tracking to create tamper-proof audit trails for every part so that you can avoid penalties and recalls.

Our data engineering frameworks link defects to machines, batches, and operators in real time, giving engineers clear insight to fix problems fast.

Using edge-ready AI deployments, you can add new lines or products without extra inspectors. Compute capacity scales automatically while maintaining high accuracy.

Below are the key features that use AI vision and analytics to detect defects. Each key feature streamlines quality checks, reduces waste, and ensures consistent product excellence.

High-resolution images are inspected frame by frame as products move along the line, ensuring fine defects are caught immediately. The system also analyzes live video streams with equal accuracy. When it detects an anomaly, it sends an instant alert so operators can take corrective action right away.

Utilize deep learning models trained on comprehensive defect datasets to recognize subtle anomalies across products. These deep-learning models continuously learn from new inspection data, adjusting thresholds and parameters to stay accurate as production conditions change.

Our AI system identifies scratches, dents, cracks, and contamination early in production. Computer vision detects dimensional deviations, cosmetic flaws, and functional faults in real time. Adaptable models ensure full coverage across manufacturing environments.

Our solution adapts to varying product specifications and volumes, scaling from single lines to facilities without performance loss. Modular design maintains detection accuracy across products, preserving quality standards even as diversity and throughput increase.

Deploy AI inference at the edge to minimize latency and network dependency. Local processing analyzes images on-site, ensuring inspections continue even with limited connectivity. This empowers teams to catch defects instantly, maintain uptime, and secure data.

We evaluate your current camera setup, including lighting, angles, and sensors, and reuse it whenever specs suffice. This minimizes new equipment costs while maintaining inspection accuracy and performance.

When you introduce new equipment of the same category, only the AI model requires retraining. Our streamlined process adapts parameters quickly, reducing downtime and preserving inspection reliability.

Initial model training covers your first line end-to-end. Retraining for additional lines or similar equipment builds on that foundation at a fraction of the original effort, delivering fast ROI on new inspections.

Our computer vision solution ranges from pinpointing sub-micron defects on semiconductor wafers and electronics to identifying major structural issues like leaks or cracks in industrial vessels. This end-to-end approach provides a single solution for every inspection challenge.

Faster inspection cycles

AI checks each item instantly, removing manual delays and keeping production flow steady. Automated checks at every stage allow your team to focus on more valuable work.

Better product quality

AI identifies even the smallest issues to ensure only high-quality products reach your customers. It learns from different defect types to help maintain consistent output.

Lower operating costs

Early detection helps reduce waste, repair work, and returns. With fewer manual checks needed, your labor and material costs go down over time.

Stronger customer trust

Reliable products help you build long-term customer relationships. Accurate inspection records also support internal audits and better service delivery.

Flexible quality control

The AI solution can grow with your production needs. It connects smoothly with your current setup and supports expansion without adding more staff.

Smarter decisions in real time

Get a clear view of your production in real time, , so your team can step in early, fix issues fast, and keep production on track.

Every project begins with a deep dive into your production goals and quality challenges. We map inspection requirements, collect defect samples, and define success metrics to guide the AI roadmap. From there, our structured six-step process deploys the solution and maintains peak performance.

We start by understanding your production goals and quality challenges. We map inspection requirements, collect defect samples, and define success metrics to guide the AI roadmap.

Once samples are collected, we label images of good and defective parts and train AI models. We refine hyperparameters rigorously until precision and recall meet stringent production targets.

With models tuned, we deploy AI inspection on a single line. We track detection accuracy, false positives, and operator feedback to fine-tune thresholds, validate performance, and ensure readiness for full-scale rollout.

After a successful pilot, we integrate AI inspection with your factory control systems and dashboards for real-time alerts. Our modular setup lets you replicate configurations across additional lines and plants without downtime.

Once integration is in place, we train operators and quality teams on dashboards, alert handling, and maintenance. Ongoing support and quick-start guides ensure rapid adoption and confident use of AI-driven inspections.

After launch, we monitor model accuracy, hardware health, and defect trends. Regular retraining, threshold adjustments, and performance reports keep the system precise as product lines and factory conditions evolve.

Our AI vision and analytics adapt to diverse sectors, catching defects early, improving yield, and protecting safety. From automotive paint lines to telecom device assembly, we tailor inspections to each production environment.

Real-time inspection of paint, panels, engines, and parts to achieve zero-defect assembly.

Micron-level PCB, chip, and wafer analysis improves yield and cuts scrap.

Detect flaws in metals, plastics, packaging, and assembly processes to reduce downtime.

Check patterns, weaves, and stitching for consistent finish and fewer returns.

Ensure packaging, labeling, and surface cleanliness meet safety standards at speed.

Assess packaging and seal integrity to prevent transit damage and optimize shelf space use for efficient storage.

Detect assembly defects in POS terminals and banking hardware, and flag visual anomalies that could compromise secure, reliable transactions.

Inspect router, switch, and network equipment assembly to ensure uninterrupted service and minimize downtime.

Backed by 21 years of analytics and automation expertise and experience in AI since its inception

Proven 100% detection accuracy across trained defect types

Deep expertise from data labeling to edge deployment and MES integration

Expertise in leading vision models such as YOLOv8, Faster R-CNN, DETR, and U-Net

Certified partnerships with NVIDIA, Azure, AWS, and other leading tech platforms

Defect detection is an AI-driven visual inspection process that uses computer vision and deep learning to automatically identify flaws in products. Cameras capture images or video of items on the production line, and trained AI models analyze that visual data in real time. Any anomaly, such as a scratch, crack, or misalignment, is flagged instantly for review or automated rejection.

At minimum, you need high-resolution industrial cameras or vision sensors, consistent lighting, and an edge or server-based processing unit to run AI inference. Additional enclosures, specialized lenses, or factory-grade compute devices may be necessary depending on your environment. Proper network connectivity or local edge compute ensures that inspection data flows seamlessly into your quality-management system.

Implementation typically spans 4 to 12 weeks, depending on data availability, integration complexity, and the number of lines. A pilot deployment on a single production line can be completed in 2 to 4 weeks, including data collection, model training, and initial testing. Expanding to a full-scale rollout, with system integration and operator training, usually takes up to 4 months.

We gather representative images of both good and defective parts, then label them to build a high-quality training dataset. Data scientists train deep learning models, often convolutional neural networks, on this dataset, optimizing for precision and recall. Models are validated on a separate test set and refined iteratively until they meet your specific production accuracy targets.

Costs vary based on hardware selection, the number of inspection points, and the level of customization required. A typical turnkey solution includes cameras, compute devices, software licenses, and integration. We work with you to calculate ROI by quantifying scrap reduction, labor savings, and improved throughput to ensure a justified investment.

By catching defects early, before products advance through the line, AI detection prevents rework, scrap, and costly recalls. Automated inspections ensure consistent quality checks on every item and eliminate human variability. This leads to fewer returns, higher yields, and lower labor expenses, directly boosting your profit margins.

Yes. Our solution automatically logs defect data, inspection timestamps, and images for every batch, creating a complete audit trail. You can generate customized reports on demand, export data to CSV or BI tools, and maintain detailed records that satisfy regulatory requirements without manual record-keeping.

We offer 24/7 technical support, regular software updates, and prioritized troubleshooting to keep your system running smoothly. Model retraining services ensure accuracy as new defect patterns emerge, and periodic health checks monitor device performance. Our service contracts can be tailored with SLAs that match your operational needs and uptime requirements.

Yes. Our solution plugs into your current workflows and records all inspection results and images on your on-premise servers. When integrated with PLC and SCADA, our platform sends real-time signals to diverters or actuators that automatically separate defective units on the line, ensuring only quality parts continue downstream.

Vision-based systems detect a wide range of visual defects at the EOL stage to maintain product quality and compliance. Common issues include surface cracks, dents, scratches, contamination, misalignments, missing components, labelling errors, and packaging defects. The systems analyze products in real time, flagging anomalies so only items meeting quality standards move downstream. A computer vision-based EOL stage check is applicable across industries such as automotive, electronics, manufacturing, and pharmaceuticals.

Vision-based EOL defect detection improves manufacturing efficiency by making inspections faster, more accurate, and more consistent. This reduces waste, cuts costs, improves product quality, and lowers return rates. Using computer vision and AI, it can even detect micro-defects and subtle anomalies that human inspectors may miss, improving reliability, reducing rework, and increasing throughput.

Automated visual inspection systems powered by machine vision are widely used across industries like automotive, electronics, healthcare, and food processing. Typical tasks include defect detection, dimensional measurement, assembly verification, label and code checks, and packaging inspection. By improving quality control and boosting efficiency, these systems play a vital role in building smarter factories.

Innovative AI defect detection solutions, delivering results at the edge

Take the next step towards AI innovation