Data connects manufacturers with their production lines and customers in a powerful way. And analytics turns the connection into efficiency, productivity, and innovation.

For instance, sensors on machines can collect real-time data during production. They can monitor equipment performance, production schedules, and workflow management. Analytics tools can process the collected data to identify opportunities, streamline operations, and improve throughput.

Ultimately, data analytics helps run manufacturing facilities more efficiently, provide better products to customers and innovate at a faster pace.

Therefore, in this blog post, we are going to cover the role of data analytics in manufacturing, its benefits, and use cases so that you can apply data analytics with a complete understanding and maximize its value.

Let’s learn.

What is the role of data analytics in manufacturing?

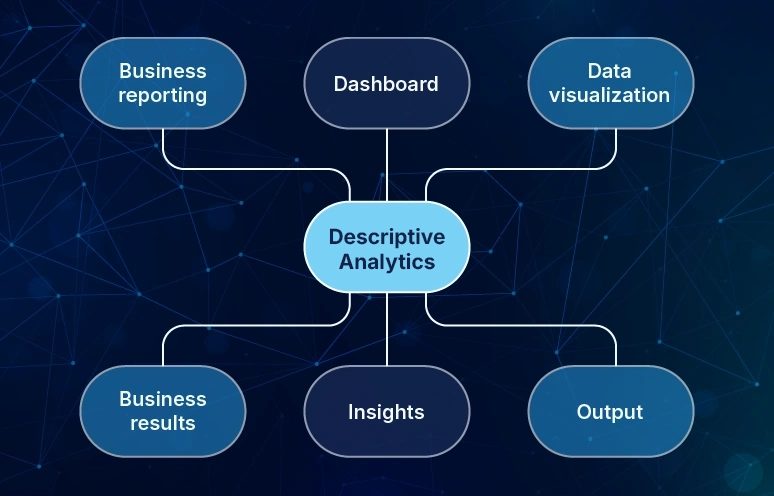

Data analytics brings real-time awareness for manufacturers. It provides insights into production, operations, supply chains, customers, market, and much more. The purpose of data analytics is to have an explanation for every event so that manufacturing teams can make data-driven business decisions.

The most deployed technology use case in manufacturing is data and analytics for process improvement. 72% of manufacturing companies are currently deploying or have fully deployed data and analytics.

Source: Gartner research (Manufacturing emerging technology priorities and progress by use case)

A few data analytics technologies are IoT, big data, predictive analytics, AI and ML. They help manufacturers collect and analyze data about machine health, products, quality, inventory, workflows, customer satisfaction, market, etc. And the insights can help them make informed business decisions to increase productivity, develop new customer experiences, and improve environmental impact.

How to streamline production with data analytics?

Data analytics can help you track how each step in your production system performs. Starting from data collection, it captures data in real-time from machines, sensors, workflows, and systems on the floor. It can include:

- Equipment health

- Production speed

- Downtime

- Product quality

Then, analytics tools process data to find patterns and highlight inefficiencies. For example, they can:

- Detect machines that are underperforming

- Find workflows that cause delays

- Identify production steps that lead to quality issues

With real-time production insights, you can take targeted actions. For example, you can remove unnecessary production steps, schedule maintenance before breakdowns and adjust production as per the demand.

And to achieve consistent improvement, your production teams can track the results of changes, measure performance, and refine the processes.

How to optimize supply chains with data analytics?

Supply chains are complex. And data analytics brings structure and clarity. It can provide data about suppliers, warehouses, transport, and external sources. For example, weather forecasts.

Next, with data analytics tools, you can monitor supplier reliability, inventory levels, delivery timelines, and transportation efficiency. And then, using the gathered insights, you can make timely decisions to avoid delays, product shortages, and excess inventory.

Additionally, you can use predictive analytics to increase overall efficiency. It can help you forecast potential disruptions such as delivery failures and sudden demand shifts. Using such insights, it supports proactive planning and reduces operational uncertainty.

How to achieve operational excellence with data analytics?

Data analytics provides visibility into every part of manufacturing operations, from the shop floor to logistics, resource management, and customer delivery. Here’s how:

-

Proactive equipment management

Data analytics helps monitor machine performance. Using predictive models, it helps identify early signs of equipment failure such as temperature changes. As a result, you can schedule maintenance before downtime.

-

Real-time quality control

Analytics helps track quality data in real time as products move through each stage of production. It can detect deviations and find their root causes so that you can adjust your processes efficiently. And ultimately, ensure consistent product quality with minimum defects.

-

Workforce and resource optimization

Data analytics tools can track labor efficiency, materials usage, and time spent throughout operations. They provide information about lost time, overused or underused resources, and overall shift performance. And its analytical insights help manufacturing teams plan shifts better, reduce overtime, and avoid material shortages.

-

Faster decision-making

A few data visualization tools such as live dashboards and alerts keep teams informed without having to wait for reports. Therefore, when something changes, such as a delay, a drop in output, or a sudden spike in demand, your manufacturing teams can find out early. Then, they can respond quickly and take actions with more confidence.

Key business benefits of manufacturing analytics

When processes improve, operations scale. And when operations scale, business grows. Here are a few meaningful ways data analytics impacts the bottom line.

-

Reduces time from lead to fulfillment

With analysis of order patterns, production schedules, and real-time floor performance, manufacturers can shorten the time from order to delivery. And faster cycle times lead to improved customer satisfaction.

-

Increases asset ROI

Every machine is a capital investment. Analytics helps ensure those assets are working at optimal capacity and are not sitting idle, overused, or underperforming. It improves throughput per asset and extends equipment life, ultimately, helping businesses maximize return on capital expenditure.

-

Reduces Cost of Poor Quality (COPQ)

Data analytics can reduce hidden costs associated with quality failures. They include scrap, rework, warranty claims, and lost customers. By detecting early quality signals, manufacturers can correct processes before problems escalate to save time and money.

-

Lowers energy and utility spend

Analytics helps track and optimize energy use down to individual machines or zones. By identifying peak load periods, idle power drain, or inefficient systems, manufacturers can cut energy costs and support sustainability targets with clear metrics.

-

Improves margin per product line

Not all products deliver the same return. Therefore, by connecting production data with costing and sales, analytics helps learn which product lines are truly profitable and which are driving up waste, downtime, or excess resource use.

-

Increases forecasting accuracy for financial planning

Financial performance in manufacturing is tied closely to operations. With better data from the shop floor and supply chain, finance teams can build more accurate revenue, cost, and margin forecasts and improve planning and investment decisions.

5 use cases of data analytics in manufacturing

There are many ways data analytics can be applied in a manufacturing facility. To start with, we have listed the five high-impact use cases where data analytics can make a measurable difference.

-

Predictive maintenance

Manufacturers use data analytics to reduce equipment failures. They track real-time machine signals such as vibrations, temperature, and noise. And then, applying predictive models, they identify early signs of wear and schedule maintenance. Ultimately, the insights help them avoid costly downtime and improve technician productivity.

-

Demand forecasting

Data analytics helps manufacturers align production with real market demand. They can analyze historical sales, seasonal trends, promotions, and even macroeconomic signals to understand the demand. With better forecasting accuracy, companies can reduce stockouts and overproduction, avoid excess inventory costs, and improve order fulfillment and contribute to healthier margins and happier customers.

-

Inventory management

Analytics brings real-time visibility into raw materials, WIP, and finished goods inventory. Therefore, manufacturers now can track stock movement, identify slow-moving and excess items, and most importantly, set data-driven reorder points. An absolute level of control helps reduce holding costs, prevent stockouts that halt production, and streamline procurement planning.

-

Quality control

Real-time quality monitoring powered by data analytics allows manufacturers to detect defects and deviations as they take place on the production line. Using inspection data, sensor readings, and AI-based image recognition, teams can act on quality risks earlier. This minimizes rework and waste, improves customer satisfaction, and helps maintain regulatory compliance at a scale.

-

Energy management

Data analytics tools and technologies help track energy consumption across equipment, lines, and facilities. They identify patterns like peak usage, idle-time energy drain, and inefficient systems. And using the insights, manufacturers can optimize energy consumption and reduce energy spending. It helps them cut utility costs and support their ECG goals while creating opportunities for sustainability-driven innovation.

Next: Start small, but start with data

To make the most of data analytics across your operations, you can start by identifying one area with room for improvement such as production downtime, quality issues, or excess inventory excess. Then, bring in data: What are you already tracking? What is missing?

You don’t need a full digital overhaul to get value. Even small wins like spotting a recurring delay, finding a cost-saving in energy, or improving forecast accuracy can build momentum.

Over time, as teams see the impact, data analytics will become part of how decisions are made, and business goals are achieved.