The client is a large-scale manufacturer and distributor of wafers used in the production of electronic devices like desktops, laptops, smartphones, televisions, washing machines, digital cameras, and refrigerators. They also offer diagnostic services and wafer customization services. They serve clients in the electronics, biotech, and nanotechnology industries. The company is operational since more than five decades and has its head office in the USA, and registered offices in China and Japan.

Semiconductor wafers are crucial in the electronic world because they serve as the base material for creating electronic components like transistors, resistors, and capacitors. Our client, being a leading provider of wafers, had to manufacture wafers in huge volumes. Defect detection is an important part of production as wafers must be checked for quality before rolling out. Our client struggled with:

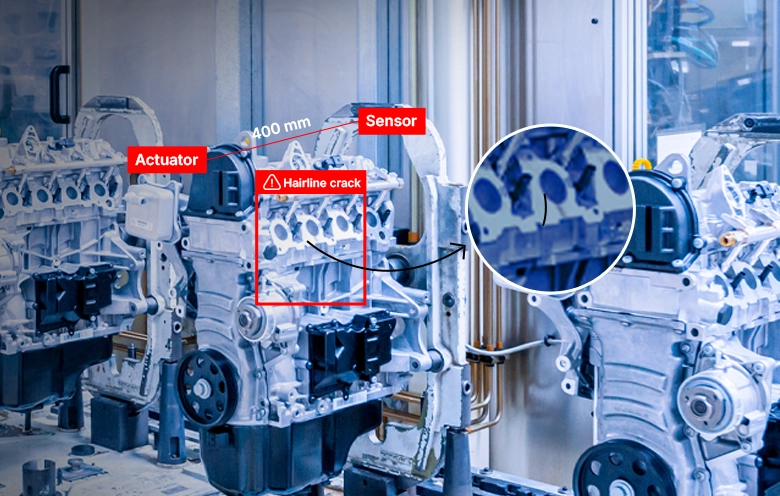

Manual defect detection process - Their manual defect detection process was tedious, time-consuming, and prone to errors. This led to delays in production and affected order delivery ETAs.

Inefficient system – Their old system was not accurate in distinguishing relevant and irrelevant images. This resulted in poor quality production which slowed down their operational efficiency.

Inability to fulfill orders – As production was affected due to the above reasons, they were not able to fulfil the demands of their distributors and suppliers in time.

Our team conducted thorough consultations with the client’s team. We proposed developing a backend solution using deep learning technology to identify defect patterns and perform image classification effectively. Our solution development process included:

Python, TensorFlow, Keras, Azure Blob Storage

Projects

Technocrats

Products and Solutions

Customers

Connect Now

Our experts would be eager to hear you.