Customer background

Ingersoll Rand is a diversified industrial company with manufacturing facilities in over 99 countries. The company manufactures products that are used extensively in the construction, mining, industrial and commercial markets. Some of its popular products are HVAC equipment, pumps, golf cars, compressed air solutions, air compressors, and material handling devices.

Challenges

Compressors are an essential part of Ingersoll Rand. Their manufacturing process relies on compressors. Hence, it is crucial to run them effectively without failure. The company was unable to constantly monitor them to understand their performance.

It was difficult for the client to gain insights into key parameters of the machines and predict failure beforehand. Running diagnostics and deciding on important aspects like changing damaged parts or forecasting maintenance were a few of the challenges faced by Ingersoll Rand.

Solutions

Softweb Solutions leveraged the benefits of IoT solutions to address these issues. Our data analytics experts thoroughly analyzed each problem statements and suggested Avnet’s IoT platform, /IOTCONNECT®. The platform offers the required infrastructure and smart solutions that help Ingersoll Rand address their business challenges efficiently.

Remote monitoring

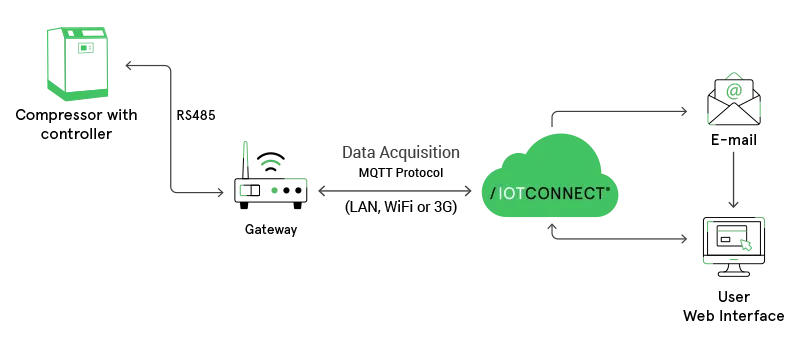

Our data scientists worked to gain insights from their data. The /IOTCONNECT® platform has connectors to gather data from disparate sources. The compressors continuously report the operating status of their internal parameters (oil temperature, oil pressure, stage 1 temperature, motor current, system pressure, etc.) over a secure internet connection. With sensors in place, the IoT platform gets all the data in one place. If any anomaly is detected in the given parameters, maintenance workers are alerted via email notifications for decision-making.

Predictive analysis

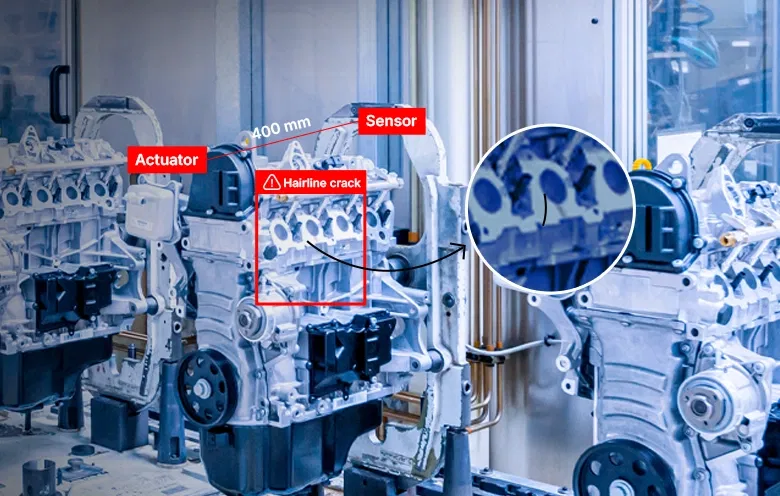

With predictive analytics, Ingersoll Rand can promptly identify the onset of equipment failure and take proactive measures. Equipment issues are detected by threshold values and the operations managers are sent a notification alert with the anomaly details. With information about the repair or maintenance work handy, the company can save on shipping costs, rather than having to bring all the possible components to the customer site.

- Gain insights into compressor operation by analyzing real-time data and trend charts.

- Prevent unexpected downtime and achieve “worry-free operation” with easy access to unique equipment information, such as maintenance consumables and contract details.

- Reduce on-site maintenance time by monitoring the operating status of compressors and reprocessing equipment deployed across regions and factories – anytime, anywhere.

- Initiate urgent repairs immediately by detecting unusual operating conditions like pressure, temperature, etc.

- Send email notifications to service centers, thus minimizing equipment downtime.

Transforming business

-

Industry

-

Technologies / Platforms / Frameworks

Node.js, AngularJS, MySQL, /IOTCONNECT™ platform, Java

-

Benefits

- Get insights-driven analysis

- Predictive analytics for preventive maintenance

- Smart rule configuration

- Anomaly detection

- Reduced unscheduled downtime

Decades of Trust & Experience

1630+

Projects

545+

Technocrats

26+

Products and Solutions

1020+

Customers

Similar Case Studies

Enhanced quality control system for a manufacturing company with machine learning

Streamlined invoice reminder processes with RPA for a leading manufacturing company

Digital health & remote patient monitoring for Primsphera with IoTConnect

Connect Now

Our experts would be eager to hear you.