The development of recent crises, such as COVID-19 and the Middle Eastern crisis (nine crises are ongoing at 11 locations since October 2023), natural disasters, and disruptive technologies like Artificial Intelligence (AI) have transformed supply chain management and business in general. These disruptions have an effect on the (re)definition of performance and decision-making processes.

70% of companies have experienced significant supply chain disruptions over the past five years, resulting in substantial financial losses and decreased customer satisfaction.

Source: The Business Continuity Institute (BCI) in an annual supply chain resilience report

Thus, supply chain executives across production, delivery, distribution, and procurement operations are embracing AI technologies to mitigate these risks. Among these AI technologies, Generative AI (GenAI) is a force multiplier. It can make supply chains more resilient, flexible, and intelligent so that they can withstand shocks and recover rapidly.

In this blog post, we will discuss how companies using generative AI in supply chain management can gain significant operational gains, such as better customer satisfaction, cost reduction, and increased process efficiencies. We will cover key benefits, practical use cases, and real-world examples of AI-based supply chain management to illustrate this point.

What is generative AI in the supply chain?

Generative AI in the supply chain refers to the use of algorithms that can create new content – whether text, images, videos, code, or three-dimensional representations – to predict outcomes and optimize processes. The main difference between GenAI and traditional AI is that the former can generate novel, contextually relevant content rather than analyzing and acting on existing data.

Unlike traditional AI systems that require explicit programming for task execution, GenAI operates through human-machine conversations. Generative AI systems learn from interactions to produce increasingly relevant outputs. This conversational approach makes it more intuitive and accessible for supply chain professionals who may not have deep technical backgrounds.

GenAI is built on AI technologies such as neural networks and deep learning algorithms. For example, ChatGPT utilizes Large Language Models (LLMs) trained on massive parameters to understand the relationships between data and generate predictions about what content should be generated. Many generative AI companies in USA are leading the development of these foundational technologies that enable supply chains to handle complex scenarios with unprecedented accuracy and speed.

What are the benefits of generative AI in supply chains?

Generative AI offers numerous benefits in supply chain management, including improved forecasting of demand, better inventory management, and logistics. Generative AI does this by making supply chains more resilient, flexible, and intelligent.

Resilience refers to the capacity of a supply chain to forecast, prepare for, respond to, and recover from disruptions.

Flexibility refers to the ability of a supply chain to respond to shifting demand and supply circumstances without runaway cost build-up and delay.

Intelligence provides analytical richness to the supply chain in that it enables systems to analyze vast volumes of information, identify patterns, and enable decisions in real-time. It empowers predictive analysis, scenario modeling, and autonomous reaction.

There are primarily four benefits of employing generative AI in supply chain management:

- Enhanced sourcing evaluation and supplier collaboration

- Greater resilience through active risk mitigation

- Better coordination among logistics, distribution, and transportation

- More accurate procurement and optimized inventory management

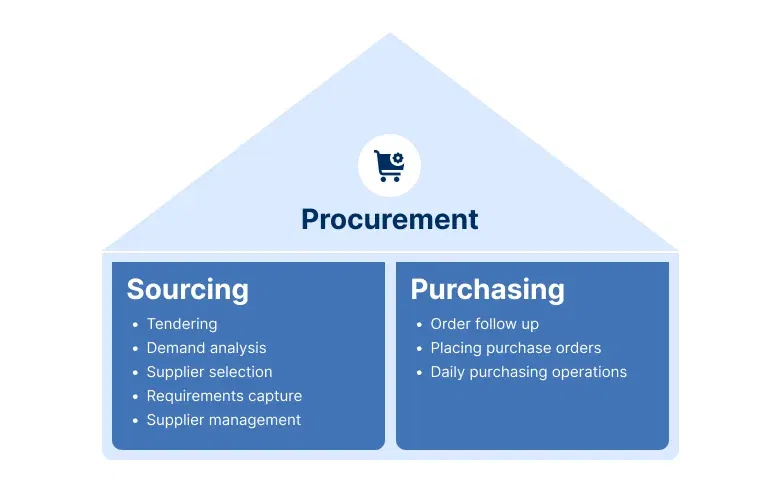

Enhanced sourcing evaluation and supplier collaboration

GenAI technology can swiftly sift through extensive data from numerous potential suppliers. It can consider parameters like cost-effectiveness, product quality, reliability, operational efficiency, sustainability, and more to craft an optimal supplier portfolio. In addition, using its text generation capabilities, GenAI provides details with each supplier’s strengths and weaknesses.

In addition, the technology also helps create varied negotiation strategies and contractual terms from historical data and expected supplier actions. Generative AI processes huge sets of data quickly and comprehensively. Thus, it revolutionizes the sourcing and procurement arena by assisting you in the supplier selection process.

Greater resilience through active risk mitigation

The use of generative AI in supply chain management analyzes historical data, trending patterns, and external factors. It creates scenario-based risk analyses that include occurrences such as supplier insolvency, labor strikes, natural disasters, pandemics, and other possible risks. Supply chain managers can plan strategies and take preventive measures in case of future disruptions.

Companies like Unilever, Johnson & Johnson, Amazon, Walmart, and several others have implemented generative AI-powered supply chain management. Their supply chain managers are leveraging this technology to create bespoke backup strategies for various categories of risks. They then verify these plans through simulations to make sure that they have the capacity to address disruptions effectively while keeping operations running uninterrupted.

Better coordination among logistics, distribution, and transportation

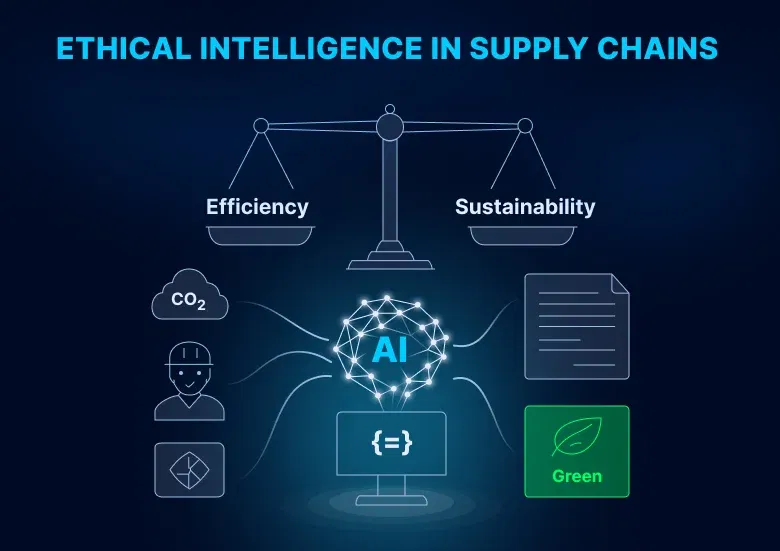

Generative AI is particularly effective at creating complex plans that optimize logistical and distribution routes while managing a variety of goals and constraints. These include reducing costs, optimizing service levels, minimizing routing disruptions, considering weather conditions, and incorporating environmental factors. Efficiency, not at the cost of sustainability. Such coordination enables you to maintain the balance as you see in the following image. That’s how AI-based supply chain management plays a crucial role in ethical decision-making.

AI algorithms intelligently optimize the best routes for transportation using real-time parameters, such as weather conditions, vehicle specs, traffic flow, and fuel prices. Generative AI can make written descriptions available for specific routes enhances its value. This aspect offers logistics managers ample route choices, allowing them to make informed decisions.

More accurate procurement and optimized inventory management

Generative AI technology, with its predictive capabilities, provides precise projections of sales and demand, enabling firms to schedule supplier quantities and orders for optimal scheduling. This accuracy makes it easier to apply lean management techniques, which significantly cuts waste and increases process and resource efficiency.

Generative AI can also generate plans for just-in-time inventory management, which is a method that can save storage costs and improve cash flow. Generative AI also forecasts changes in consumer patterns and market trends, along with demands, using predictive analytics. Thus, companies can adapt rapidly and optimize excess stocks while equating shifting demands with optimal inventory levels.

Top 10 Use Cases of Generative AI in Supply Chain

If you’re looking to elevate your supply chain, the real question isn’t whether to use AI, but how rapidly you can implement it to achieve transformative outcomes. Generative AI empowers smarter planning, risk management, and optimization—here’s how:

-

Demand Forecasting

Generative AI algorithms process large volumes of past sales data, including seasonality, promotions, and economic conditions. Trained using detailed datasets, businesses can produce more precise demand projections that enable the optimization of inventory control, resource planning, and market trend forecasting. Real-world impact: Amazon’s GenAI algorithms predict demand and pre-optimize inventory throughout its massive network of warehouses. They scan enormous data sets containing historical sales, customer patterns, and external influences like holidays and promotions.

-

Supply Chain Optimization

Generative AI models have the ability to examine various sources of visual or textual information, including traffic updates, prices of fuel, and weather forecasts, to identify the most efficient routes and schedules for transport. Generative AI generates various scenario options and, based on your optimization criteria, it suggests the most appropriate solutions for cost minimization, lead-time minimization, and optimized operational efficiency.

-

Supplier Risk Assessment

Through the examination of big volumes of data, including historical supplier performance, accounting reports, and news articles, generative AI supply chain models can identify trends and patterns related to the risks of suppliers. Through these patterns and trends, companies can evaluate supplier reliability, predict potential disruptions, and respond by imposing proactive risk avoidance strategies.

-

Anomaly Detection

Through the analysis of information on all sides of the supply chain, generative AI supply chain models can detect anomalies or deviations from the norm. This feature allows companies to rapidly detect impending problems, such as bottlenecks, quality issues, or unforeseen demand shifts before they become serious problems.

-

Product Development

Generative AI can take market data, customer inputs, and competitor data as input and produce insights regarding possible gaps or opportunities in the market. The analysis shortens innovation cycles and enhances product-market fit by detecting nascent trends and unserved customer needs.

-

Sales & Operations Planning

Generative AI solutions can combine sales, marketing, production, and distribution data to create more precise and accurate plans. This combination enables companies to align strategies within departments, streamline the allocation of resources, and react better to the changing market.

-

Price Optimization

Generative AI supply chain models are able to examine variables like market conditions, customer demand, and competitor price to produce best-practice pricing strategies. Such strategies help businesses optimize revenue and profit margins and provide a competitive advantage.

-

Transportation & Routing Optimization

Generative AI is critical in transportation and routing optimization for supply chain management. The technology provides route optimization with the least costs, vehicle and fleet optimization, and dynamic routing which adjusts to disruptions and delays. Success story: UPS’s ORION system uses AI to plan the best delivery routes in real time based on package volume, delivery windows, traffic, and weather. ORION has saved UPS more than 10 million gallons of fuel per year, reducing costs and greenhouse gas emissions as well as enhancing on-time delivery performance.

-

Inventory Management

Generative AI models have the capability to review demand patterns, lead times, and so on to calculate optimal inventory levels at different stages of the supply chain. Through the creation of reorder point and safety of stock level suggestions, AI minimizes stockouts, reduces overstocking, and lowers carrying costs.

-

Financial Optimization

The use of generative AI in financial services and operations for supply chains can greatly help supply chain management through increased efficiency, reduced risks, and enhanced decision-making procedures. The use includes credit risk evaluation, fraud identification, and avoidance, as well as full-spectrum risk management in financial operations.

5 real-world examples of generative AI in the supply chain

1. Maersk revolutionized customer service with GenAI

Challenges faced: Maersk, as a global leader in container shipping, faced significant challenges in managing the high volume of customer inquiries across multiple channels. Traditional customer service methods were struggling to provide consistent, accurate responses to complex shipping-related questions, leading to customer dissatisfaction and increased operational costs.

Adopted GenAI strategies: Maersk implemented ChatGPT on their website (Maersk.com) to automate responses to frequently asked questions. The AI system was trained on comprehensive shipping knowledge bases, enabling it to provide accurate, contextually relevant responses to customer inquiries about shipping rates, schedules, documentation requirements, and tracking information.

Impact: The AI implementation has improved query accuracy and contributed to a significant increase in website traffic. The company expects to expand its GenAI-based services to offer enriched customer experiences, including more prompt and accurate responses to customer requests, ultimately improving overall customer satisfaction and operational efficiency.

Source: Maersk

2. Walmart transformed procurement through GenAI-powered negotiations

Challenges faced: Walmart’s massive procurement operations required negotiating with thousands of suppliers across various product categories. Manual negotiation processes were time-consuming, inconsistent, and often failed to achieve optimal pricing and terms due to human limitations in processing multiple variables simultaneously.

Adopted GenAI strategies: Walmart deployed an AI chatbot specialized in autonomous negotiations. The system considers multiple variables, including payment terms, discounts, prices, historical trends, and market conditions, to inform buyers of the optimal price points suppliers are likely to accept. Such an AI-driven approach standardizes negotiation processes while leveraging data-driven insights.

Impact: The AI-powered negotiation system has achieved a 68% success rate in deal negotiations, generating 3% savings on contracts. Walmart’s supply chain achieved significant cost reductions while maintaining strong supplier relationships and improving procurement efficiency.

Source: CIO

3. Unilever enhanced consumer engagement through intelligent communication

Challenges faced: Unilever faced overwhelming volumes of consumer inquiries across multiple channels, requiring significant staff resources to manage email filtering, spam sorting, and response preparation. The manual process was inefficient and prevented staff from focusing on more strategic consumer engagement activities.

Adopted GenAI strategies: Unilever implemented a GPT API-based system to enhance consumer engagement and relationship management. The AI system automatically filters emails, manages spam sorting, and provides recommended responses to human teams. Additionally, the system analyzes consumer questions and stores sentiment data for future strategic use.

Impact: The implementation has reduced staff time spent preparing replies to queries by 90%, allowing human teams to focus on more complex consumer relationship management tasks. The system can analyze consumer sentiment and store valuable data for future strategic decision-making, significantly improving operational efficiency and consumer satisfaction.

Source: Bloomberg

4. Mercedes-Benz optimized production through voice-enabled AI

Challenges faced: Mercedes-Benz’s complex production processes required continuous monitoring and optimization to maintain quality standards and operational efficiency. Traditional systems struggled to provide real-time insights and recommendations for production optimization, quality management, and error identification.

Adopted GenAI strategies: Mercedes-Benz implemented voice-based ChatGPT integration within their digital production ecosystem. The AI system supports key operations and supply chain management (OSCM) processes, including production optimization, quality management, and real-time data analysis. The voice interface enables hands-free operation in manufacturing environments.

Impact: The company expects ChatGPT to optimize production data analysis, improve error identification capabilities, enhance quality management processes, and drive overall process optimization. This implementation represents a significant step toward fully integrated AI-driven manufacturing operations.

Source: Just Auto

5. Tel Aviv Sourasky Medical Center revolutionized healthcare supply chain through GenAI triage

Challenges faced: The medical center encountered difficulties in efficiently managing clinical processes and patient triage, resulting in staff burnout and inadequate resource allocation. Traditional triage systems were time-consuming and often led to suboptimal prioritization of patient care.

Adopted GenAI strategies: Tel Aviv Sourasky Medical Center became the first hospital to integrate an AI chatbot to support clinical processes. The system assists physicians and nurses by providing robust patient condition summaries and valuable insights about diagnostics and treatment next steps. The AI system streamlines triage processes while maintaining clinical accuracy and precision.

Impact: The organization anticipates a significant improvement in the efficiency and accuracy of clinical processes. The implementation reduced staff burnout by allowing medical and nursing staff to focus on treatment plans rather than administrative tasks.

Source: NoCamels: Israeli Tech and Innovation News

Why Softweb Solutions is the right partner for generative AI implementation

Softweb Solutions offers generative AI services focused on solving real-world supply chain challenges. Unlike many generative AI companies in the USA that offer one-size-fits-all solutions, we combine deep supply chain expertise with advanced AI capabilities to deliver business-specific results.

Our approach begins with a thorough assessment of your current processes. We then design tailored AI solutions for key areas like demand forecasting, supplier risk, inventory planning, and logistics. Our consultants help you select the right tools and technologies to meet your objectives. More than just implementation, we ensure measurable gains in supply chain resilience, agility, and intelligence.

Let’s connect to explore the scope of updating your supply chain with generative AI

The evidence is clear: generative AI reshapes how supply chains operate, compete, and deliver value. From Maersk’s customer service revolution to Walmart’s procurement transformation, leading companies leverage generative AI to achieve substantial operational improvements, cost savings, and competitive advantages.

Every day of delay represents missed opportunities for optimization, risk mitigation, and enhanced customer satisfaction. Take the first step toward transforming your supply chain operations. Contact our team today to discover how generative AI can revolutionize your supply chain performance and drive sustainable business growth.