Traditional supply chain used to be predictable and cost-effective. But in a world where constant change and disruption have become a norm, the traditional approach is no longer sufficient. Enter the digital supply chain, that isn’t just a modern upgrade, but a necessary overhaul. The digital supply chain enhances visibility, agility, and decision making across every stage. It integrates advanced analytics, data and automation to quickly and intelligently respond to the changing environment.

In this blog post, we will explore what digital supply chain is and technologies enabling digital transformation in the supply chain process.

What is a digital supply chain?

A digital supply chain is a supply chain whose foundation is built on web-enabled capabilities. Many supply chains use a mix of paper-based and IT-enabled processes. A true digital supply chain goes far beyond this hybrid model to fully capitalize on connectivity, system integration and the information-producing capabilities of smart components.

Unlike traditional supply chains, digital supply chains are more dynamic and quickly adapt to the changing work environment. Digital supply chain management is the process of maintaining and supporting your supply chain via a cloud-based software platform rather than using outdated technologies.

Cloud platforms, automation, and real-time data help businesses improve supply chain visibility and decision-making capabilities. This helps organizations respond faster to change, avoid delays, and reduce costs.

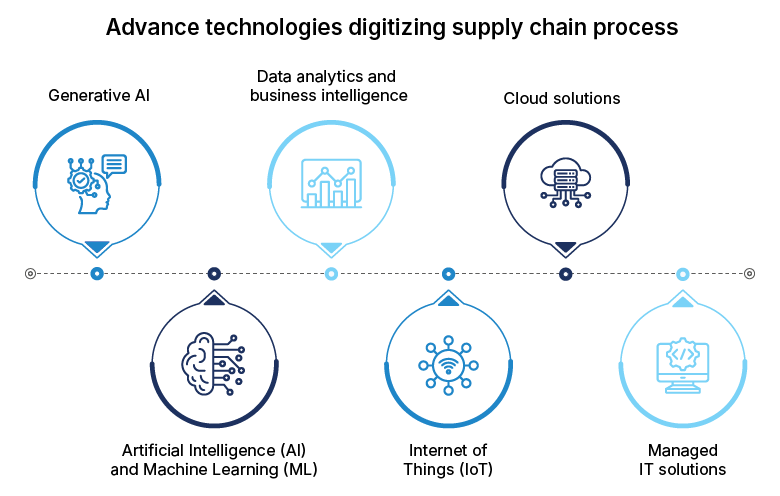

Top 6 technologies digitizing the supply chain process

From generative AI to managed IT solutions, technology is digitizing how supply chain operates. These technologies don’t just improve efficiency; they play a vital role in framing smarter and more resilient supply chain networks. Let’s now explore the key technologies that enable businesses to digitize their supply chain process.

1. Generative AI

Generative AI is an advanced machine learning model that accurately forecasts, plans and simulates outcomes based on patterns learned from large set of data. Beyond analysis, it generates context-aware insights that help businesses in strategic decision-making process. Generative AI predicts demand shaping and automate risk mitigation when integrated with digital supply chain process.

For instance, when there is an interruption in the supply chain process, generative AI produces an alternative sourcing strategy that balances cost, lead time and capability. By enhancing responsiveness and reducing planning cycle, it streamlines intricate processes and enables business leaders to act decisively in uncertain environments.

2. Artificial Intelligence (AI) and Machine Learning (ML)

AI and machine learning are technologies that enable applications to learn from data and make informed decisions without human intervention. AI-powered systems work effectively when data is well managed, combined, and stored to get the expected outcome.

AI when combined with machine learning mimics human intelligence, creates a system, and performs tasks that would require human thinking. By analyzing a large set of historical data in real-time, AI and ML streamline logistics planning, inventory management and demand forecasting.

Organizations can automate the process to detect anomalies, identify risks, and prevent disruptions by adopting robust digital supply chain solutions.

For instance, retailers can use machine learning models to predict seasonal trends and avoid stockout and overstocking. This not only improves efficiency but also enhances responsiveness across all supply chain platforms.

3. Data analytics and business intelligence

Advanced data analytics offers real-time insights, trend forecasting, and performance monitoring across the supply chain platform. Raw data is converted into actionable intelligence using data analytics, which allows businesses to anticipate demand, optimize inventory, and reduce lead times.

Analytics in digital supply chains can be classified into two sections:

- Predictive analytics enables companies to anticipate disruption within the supply chain. Data and machine learning are used to predict results based on historical data. Thus, predictive analytics helps companies foresee a surge in product demand, plan pricing, promotions, or resource allocation in advance.

- Descriptive analytics enables organizations to understand the status of their supply chain. Data that is gathered in different stages of the distribution channel can be used by the supply chain planning team to track the status of the product or services. This enables smarter decision-making in inventory planning, sourcing, and capacity planning—reducing risks and improving responsiveness.

4. Internet of Things (IoT)

The Internet of Things is a system of interconnected devices, sensors, and machines that operate beyond conventional computing platforms. It offers real-time visibility, monitoring, automation, and data-driven insights that improve performance across the supply chain. Smart sensors and connected devices enhance asset tracking, condition monitoring, and remote management. Moreover, IoT-powered predictive maintenance reduces downtime and enhances asset lifespan.

For instance, businesses can monitor their shipping containers and track the temperature, location, and handling conditions throughout transit. If there is a delay or deviation, leaders are alerted instantly so timely decisions can be taken. This reduces waste and downtime, enhancing customer experience.

5. Cloud solutions

Cloud-based networks assist organizations in rapidly and securely responding to evolving market conditions and moving into new markets. A digital supply chain enables organizations and individuals to leverage shared data to enhance decision-making and collaboration in a dynamic ecosystem. This shift enables organizations to develop resilience and agility in the supply chain process.

For example, an international retailer utilizing a cloud-based supply chain system can reroute stock in real-time during an interruption—avoids stockouts and eliminates delays. Cloud-based solutions are elastic, that facilitate growth without extensively rebuilding the infrastructure. In a digital supply chain, the cloud acts as the base for agility, transparency, and integration—making it an essential factor for operational excellence.

6. Managed IT solutions

Managed IT solutions provide businesses with expert oversight, proactive monitoring, and end-to-end management of their IT infrastructure. It helps in supply chain planning by offering tools for resource allocation, demand forecasting, and inventory optimization. Managed IT services provide end-to-end infrastructure management to support digital supply chain transformation.

For instance, an international manufacturer with managed IT can coordinate stock systems with order projections, allowing for timely manufacturing and delivery. Through optimization of system performance and regular uptime assurances, managed IT solutions enable supply chains to be smarter, faster, and more resilient.

Suggested: Redefining business with digital supply chain transformation in 2025

Advantages of digital supply chain

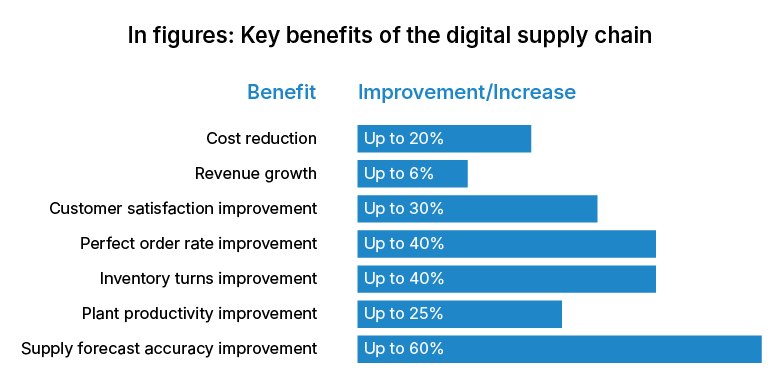

The adoption of a digital supply chain not only streamlines operations but empowers decision-making capability and fosters collaborations across all levels of the supply chain. Here are the key advantages of adopting a digital supply chain.

(Source: BCG12 and Bain & Co.13)

1. Cost savings

It saves costs through better inventory management and optimized transportation routes. Automation and advanced technologies eliminate errors and reduce waste leading to further cost savings.

2. Improved customer service

It greatly boosts customer satisfaction by enhancing product availability, transparency, and ensuring faster and more reliable delivery. Digital transformation and real-time data enable enhanced communication between suppliers and customers.

3. Improved quality control

It transforms quality control, making it possible to monitor everything from production to delivery. Integrating high-tech technology into the supply chain process ensures consistent quality, provides real-time visibility, and quickly fixes problems at every stage.

4. Optimized decision making

Businesses can now enhance just-in-time decision-making, enabling smarter, faster choices and more reliable last-minute deliveries by digitizing their supply chain process. This shift also helps reduce costs and improve overall efficiency.

5. Improved forecasts

Advanced data collection and analysis capability allows businesses to easily forecast demand and supply, enhancing production and delivery efficiency.

6. Enhanced visibility

It offers real-time visibility into the operational workflow, shipments, and inventory. This data-driven visibility helps in informed decision-making and enables organizations to adapt quickly to emerging challenges.

Transform your supply chain with solutions built for speed, resilience, and real-time insight

Our digital supply chain experts help businesses enhance visibility, improve efficiency, and reduce operational risks. We deliver scalable supply chain solutions that drive agility and resilience in modern business operations.

5 steps for digital supply chain strategy

Organizations that are in the phase of digital transformation should have a robust digital supply chain strategy that encompasses five key components, ensuring all-inclusive and productive transformation.

1. Identifying available resources

Analyze your current supply chain operations, technologies and core competencies in place. Identify vulnerable gaps in your supply chain process and frame a digital supply chain plan to address the bottlenecks.

2. Establish clear goals

Establish clear parameters or goals for your digital supply chain transformation that should be integrated with your business objective.

3. Set achievable targets

Identify high-impact areas in digitization of your supply chain process and set smaller goals that are achievable. For instance, achieving operational efficiency is easier, thus becoming a part of the bigger picture.

4. Invest in professionals and technologies

Hiring experts, who are proficient in digitizing supply chain operations ensure effective digital transformation. Leveraging their expertise in automation and application of advanced technologies like AI and ML can generate large amounts of data.

5. Automate operations

Encourage employees to adopt advanced technologies and foster the mindset for continuous improvement. This automates supplier operations, provides real-time visibility and learns from data to automate the process.

Digital supply chain use cases across industries

Manufacturing

The manufacturing industry can minimize stockouts and overstocking using real-time inventory management and sensors to track inventory levels and locations. They can use advanced technologies like AI and IoT to monitor equipment performance and predict future equipment failure, reducing maintenance and downtime.

Retail

Embracing a digital supply chain will enable companies to provide customized experience to customers by incorporating omnichannel platforms. Predictive analytics solutions monitor seasonal patterns and external influences that assist retailers in making precise demand forecasts to maximize inventory levels, enhancing customer satisfaction.

We at Softweb Solutions create tailored retail solutions that allow retailers to align inventory, order management, and customer engagement across all channels.

Telecom

Digital supply chain offers real-time data to forecast demand, predict equipment failures, or anticipate supply shortages. This helps prevent delays or outages in telecom service. Moreover, tools can be used to track carbon footprint, ethical sourcing, and regulatory compliance throughout the supply chain.

Energy

Using IoT devices, the energy industry can track critical assets across multiple sites and reduce losses due to misplacement, theft, or overstocking. The digital supply chain analyzes sensor data to predict potential failures and anticipate demand for fuel, power, or other resources.

Finance

Digital supply chain automates repetitive tasks such as loan approvals, invoice processing, KYC, and audit trails, thus ensures compliance, reduces manual errors, and saves time. Moreover, it provides live insights into transactions, vendor relationships, and customer data movement.

Digitize your supply chain process with Softweb Solutions

We provide digital supply chain solutions utilizing technologies such as generative AI, data analytics, artificial intelligence, and machine learning. This enables you to streamline processes, enhance network visibility, and react timely to evolving market needs. With domain-specific knowledge, we provide scalable solutions that foster agility and resilience in contemporary business practices.

Supply chain management digitization is the way companies are streamlining their operations, working with customers, and serving clients. Adopting digital supply chain planning allows companies to unlock new levels of efficiency, responsiveness, and innovation.

Softweb Solutions can turn your manual supply chain process into an efficient digital supply chain network. Reach out to our digital supply chain experts to digitize your supply chain process that drives agility and resilience in your business operations.