Walmart used supply chain analytics to anticipate Hurricane Sandy’s impact and preemptively shift inventory across 4,177 stores. It helped them avoid major disruption and protect $450B in revenue. It is an apt example of how supply chains, powered by data analytics, now drive strategic advantage, not just efficiency.

The cost of ignoring supply chain analytics and supply chain solutions is staggering. Companies lose an average of $184 million annually due to supply chain disruptions, according to McKinsey & Company. Its survey of 500 supply chain executives revealed that only 22% have real-time visibility into tier-one suppliers (direct suppliers) and just 6% can see beyond tier-two suppliers (suppliers of tier-one suppliers). This blind spot creates massive vulnerability in an interconnected global economy.

This blog post covers the fundamental concepts of supply chain analytics, explores its various types and applications, examines key benefits for modern businesses, and provides practical insights for implementation across diverse industry contexts.

What is supply chain analytics?

Supply chain analytics applies data science, statistical methods, and predictive modeling to optimize the movement of goods from source to customer. It analyzes every link, from procurement to delivery, to reveal inefficiencies and uncover opportunities.

By connecting data from inventory systems, logistics platforms, and supplier networks, it builds a real-time view of how the supply chain performs. This integration enables faster decisions and sharper execution.

For instance, companies like Amazon and Zara have built competitive advantages through analytics-driven supply chains that respond to market changes in real time. This is achieved by transforming raw data into insights through data visualizations and predictive models. These insights reveal what’s happening, explain why, and guide the next steps, making supply chains smarter, faster, and more responsive.

What are the types of supply chain analytics?

Supply chain analytics uses data to understand what happened, why it happened, and predict future outcomes based on specific actions. Analytics can be categorized into four distinct types: descriptive, diagnostic, predictive, and prescriptive.

Each type builds upon the previous level of sophistication. Descriptive analytics focuses on what happened, while diagnostic analytics explains why it happened. Predictive analytics estimates what is likely to happen next, while prescriptive analytics recommends actions to take in response.

Descriptive analytics

Descriptive analytics answers the foundational question: “what happened and when?” It compiles and summarizes historical data to uncover trends, monitor performance, and track key metrics across the supply chain. This type of analytics creates a baseline for more advanced techniques and ensures operational visibility. Without accurate descriptive data, supply chains cannot measure progress or respond intelligently to disruptions.

Unilever faced this visibility challenge when it discovered that 34% of supplier performance data was inconsistent across regions. After standardizing descriptive analytics across its global operations, the company improved tracking accuracy and unlocked $400 million in annual savings through enhanced supplier management.

Key applications include:

- Understanding past performance and trends

- Building supplier scorecards and benchmarks

- Analyzing inventory turnover and cost allocation

- Tracking logistics and transportation KPIs

This type of analytics relies on clean, integrated data from ERP systems, IoT sensors, market feeds, and partner systems. Real-time access to this information provides decision-makers with a stronger foundation for making faster, smarter calls.

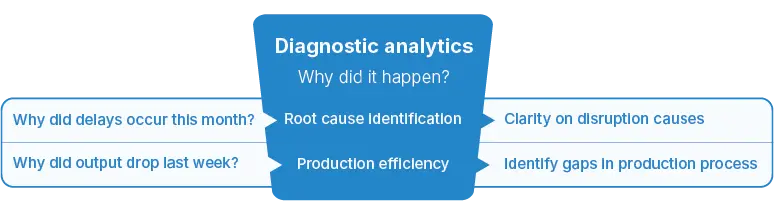

Diagnostic analytics

Diagnostic analytics digs deeper to answer, “why did it happen?” It identifies the root causes behind performance issues, disruptions, or inefficiencies. This analytical layer helps transform raw operational gaps into strategic opportunities for improvement. It utilizes statistical analysis and historical context to identify patterns that explain why variances occur and where interventions are necessary.

During the 2021 chip shortage, Ford utilized diagnostic analytics to discover that nearly half of its chip needs could be met by previously overlooked suppliers. This early insight enabled the company to reconfigure sourcing plans more quickly than its competitors, who relied solely on manual methods.

Strategic capabilities include:

- Root cause analysis of supply chain disruptions

- Performance variance investigation and pattern recognition

- Supplier relationship optimization and risk identification

- Process bottleneck identification and elimination strategies

This layer uses advanced statistical methods to link causes with outcomes, whether it’s a supplier delay, demand swing, or internal process inefficiency.

Predictive analytics

Predictive analytics shifts supply chains from reactive to forward-looking by answering “what is likely to happen next?” It utilizes statistical models and machine learning to identify correlations and forecast outcomes, including demand shifts, supply risks, and transit delays. These insights allow businesses to plan proactively, reduce uncertainty, and mitigate risks. Over time, predictive models improve as they absorb new data, providing even earlier and more accurate signals.

For example, Coca-Cola uses predictive analytics to link weather patterns, promotional activities, and regional demand. When models detect a warm spell approaching, they alert supply chain teams to increase production of high-demand beverages preemptively, helping to reduce stockouts and last-minute operational costs.

Competitive advantages include:

- Forecast demand with greater accuracy

- Identify supplier risks and predict potential disruptions

- Balance inventory across multiple locations and timelines

- Anticipate the impact of seasonal changes and promotions

These insights are derived from machine learning models that continuously analyze correlations between factors, including economic indicators, transit data, and consumer behavior. Over time, the models grow more precise, offering earlier signals and sharper forecasts.

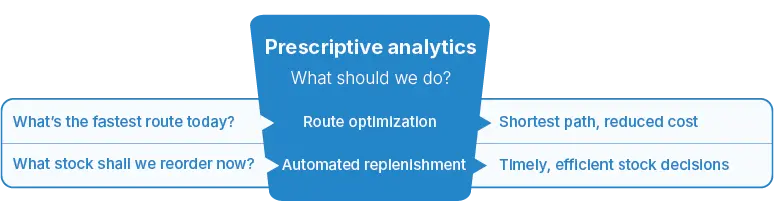

Prescriptive analytics

Prescriptive analytics answers the most advanced question: “what should we do about it?” It not only recommends the best course of action but can also automate the response. These systems evaluate scenarios, optimize trade-offs, and continuously adapt to new constraints, resulting in more consistent, timely, and scalable decisions. As operations become more complex, prescriptive analytics ensures supply chains act with precision and speed.

DHL, for instance, utilizes prescriptive analytics to optimize its global routing in real time. It processes 1.2 million variables to generate efficient delivery plans. This helped cut transport costs by 22% and improve delivery performance by 15%. UPS’s ORION system does the same, saving 100 million miles a year and cutting fuel costs by up to $300 million.

Transformational capabilities include:

- Automated decision support for routine operational choices

- Dynamic optimization of complex multi-variable problems

- Scenario planning and contingency strategy development

- Real-time adaptation to changing conditions and constraints

These systems ensure that the smartest decisions are made consistently, without relying on manual intervention, allowing teams to focus on long-term strategy.

What are the benefits of supply chain analytics?

Supply chain analytics brings tangible improvements across operations, costs, and customer experience. When used strategically, it helps organizations gain a meaningful edge in increasingly complex and competitive environments.

-

Better demand forecasting accuracy

Supply chain analytics strengthens forecasting by applying statistical models and machine learning to identify patterns that traditional methods often miss.

More accurate forecasts help avoid both overstocking and stockouts. They also lead to smarter production planning, more efficient inventory allocation, and better service levels across the board. With early insight into demand shifts, teams can act before problems escalate into costly disruptions.

-

Smarter inventory management

Advanced analytics supports dynamic inventory decisions by aligning stock levels with real-time demand, seasonality, and regional variations.

Predictive models help adjust safety stock and reorder points automatically, ensuring the right products are in the right places without tying up excess capital in storage. This level of precision enables lean operations while maintaining availability and responsiveness.

-

Stronger supplier performance and risk management

Supplier analytics offer deeper visibility into vendor performance, delivery reliability, quality metrics, and emerging risks.

This clarity enables teams to take proactive steps, such as diversifying suppliers, adjusting procurement timelines, or developing backup plans for critical components before issues escalate into costly delays. It turns supplier management from a reactive process into a strategic control point.

-

Lower transportation and logistics costs

Analytics-powered route planning and scheduling minimize transportation expenses while maintaining delivery speed and reliability.

Real-time insights into traffic, weather, and carrier capacity feed into algorithms that continuously optimize routes, saving both time and fuel with every shipment. The result is cost savings, as well as a more resilient and predictable delivery system.

-

Faster, more agile operations

With automated monitoring and real-time visibility, supply chains can respond quickly to shifts in demand, market changes, or unexpected disruptions.

This speed translates into better outcomes, whether it’s capturing short-term opportunities or mitigating risks, in industries where conditions evolve rapidly. Agility becomes a measurable advantage in how decisions are made and executed.

Key features of effective supply chain analytics

Effective supply chain analytics platforms combine advanced technology with user-friendly interfaces to deliver actionable insights. These systems must integrate seamlessly with existing operations while providing sophisticated analytical capabilities.

-

Real-time data integration and processing

Effective analytics platforms integrate data from ERP systems, IoT sensors, external market feeds, and partner systems. Real-time processing ensures that decision-makers have access to current information for time-sensitive decisions and continuous optimization.

-

Advanced predictive modeling

Machine learning algorithms and statistical models enable accurate forecasting across multiple time horizons and scenarios. These models continually improve with new data and automatically adapt to changing market conditions and business requirements.

-

Scalable, cloud-native architecture

Cloud-based infrastructure enables the handling of large datasets and complex analytics at scale. It supports global operations, seasonal fluctuations, and ongoing business growth without compromising performance.

-

User-friendly dashboards and visualizations

Intuitive dashboards transform raw data into clear, actionable insights that are accessible to supply chain professionals at all levels. Interactive reports and customizable alerts enable teams to monitor key performance indicators (KPIs), identify patterns, and respond quickly using role-based visual tools.

-

Automated decision support

The system recommends actions for routine operational choices and applies rules automatically where possible. This reduces manual effort and ensures consistent application of best practices and optimal decision-making across global operations.

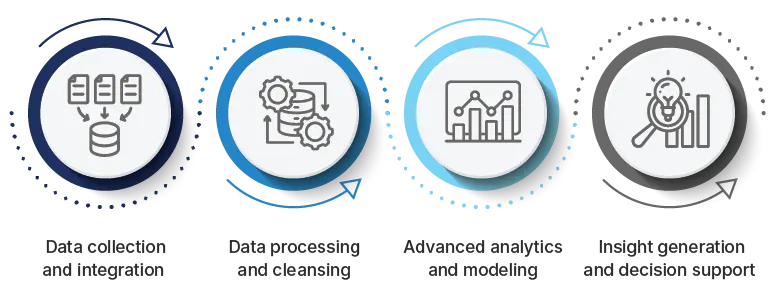

How supply chain analytics works

Supply chain analytics turns complex data into practical insights through a structured, four-phase process. Each step builds on the last, moving from data collection to real-time decision support. The result is a supply chain that is efficient, responsive, and resilient.

Phase 1: Data collection and integration

The process begins by extracting data from multiple sources, including ERP systems, supplier portals, logistics networks, and market feeds. IoT sensors, barcodes, and RFID tags track real-time movements of goods, providing live updates on inventory, transportation, and warehouse activity. Integrating these data points into a single platform creates a shared source of truth across the supply chain. This foundational step ensures all analysis is grounded in timely and consistent information.

Phase 2: Data processing and cleansing

Once collected, the data must be standardized and validated. Cleansing algorithms resolve duplicates, correct format mismatches, and fill missing values using statistical rules. Without this step, analytics outputs can be misleading or incomplete. Clean, structured data forms the basis for trustworthy insights and reliable decision-making.

Phase 3: Advanced analytics and modeling

With quality data in place, the platform applies statistical models and machine learning algorithms to spot trends and predict outcomes. It can identify demand shifts, highlight supplier risk, or uncover inefficiencies in logistics. These models continuously refine themselves with new inputs, adapting to seasonality, market shifts, or unexpected disruptions. Over time, predictions become more accurate and relevant to daily decision-making.

Phase 4: Insight generation and decision support

The final phase transforms raw analytics into clear, actionable insights through visual dashboards, scenario models, and automated alerts. Teams can monitor KPIs, compare what-if scenarios, and receive recommendations in real time. This supports quick responses to daily issues and more effective strategic planning across sourcing, production, and delivery. The right insights at the right time make the supply chain more agile, more predictable, and easier to manage.

Use cases of supply chain analytics

Supply chain analytics delivers tangible results across diverse industries and operational functions. These use cases show how analytics improves planning, performance, and resilience at every stage of the supply chain.

-

Demand planning and forecasting optimization

Retailers utilize predictive analytics to comprehend how seasonality, promotions, and external market signals impact demand. Machine learning models detect patterns in sales data that are too subtle for manual analysis and automatically adjust forecasts in real time. This improves stock availability while reducing waste from overproduction. Better forecasting also supports more accurate production schedules and smoother supplier coordination.

-

Inventory optimization across multiple locations

Manufacturers rely on analytics to align inventory with demand at each node of their distribution networks. Predictive models calculate dynamic safety stock levels and update reorder points based on lead times and current performance trends. This enables leaner inventory without risking product availability. Multi-location visibility helps reduce holding costs and improves service across markets.

-

Supplier risk assessment and management

Procurement teams use analytics to monitor supplier reliability, quality performance, and financial health. Risk models score vendors based on live data from delivery records, audits, and external sources, flagging issues before they disrupt operations. This early warning system supports smarter sourcing decisions and helps build stronger, more resilient supplier networks.

-

Transportation route optimization

Logistics teams utilize real-time analytics to plan more efficient routes and prevent disruptions. Algorithms factor in current traffic, weather, and delivery schedules to recommend optimal routes that minimize cost and maintain delivery commitments. As conditions change throughout the day, routing decisions update automatically. The result is faster deliveries and better use of fleet resources.

-

Warehouse operations and automation

Analytics helps streamline warehouse processes by optimizing layout, workforce planning, and picking efficiency. Algorithms analyze order history to position high-frequency items strategically and forecast peak volume periods. This enables better coordination between human teams and automated systems, improving throughput while maintaining order accuracy.

Your next steps: From analytics insights to competitive action

Supply chain analytics defines how modern businesses compete, adapt, and grow. Waiting to act means widening the gap between your operations and those of faster-moving competitors.

Begin by evaluating your current data status. Strengthen the basics with descriptive analytics, then scale into predictive and prescriptive models that guide smarter decisions. Choose partners who align with your operational objectives and can adapt as your needs change.

The future belongs to supply chains that think, learn, and adapt automatically. Transform your supply chain into an intelligent network that can thrive in tomorrow’s marketplace.

FAQs

What is supply chain data analytics?

Supply chain data analytics is the process of collecting, processing, and analyzing data to understand, manage, and improve supply chain performance. By analyzing inputs from across the network, teams can make more informed decisions and respond more quickly to changing conditions.

What are the core components of supply chain analytics?

The core components include data integration tools, analytics engines, machine learning models, dashboards, and decision support systems. These components work together to collect data, generate insights, and provide recommendations.

What is the primary goal of supply chain analytics?

The primary goal is to improve end-to-end performance. It sharpens visibility, cuts costs, and enhances service levels. It enables proactive decision-making and continuous improvement across all supply chain functions.

What does a supply chain analyst do?

A supply chain analyst collects and analyzes data to identify trends, optimize processes, and support strategic decision-making. They develop forecasting models, monitor KPIs, and identify ways to reduce waste, delays, and risks.

What kind of data is needed for supply chain analytics?

Essential data encompasses inventory levels, supplier performance, transportation costs, demand trends, and external factors such as weather or market shifts. Real-time data from IoT devices and tracking systems adds depth and detail.

What are the challenges to supply chain analytics?

Key challenges include data quality issues, system integration complexity, organizational resistance to change, skill gaps, and the requirements for technology investment. Companies must address these challenges to realize the full benefits of analytics implementation.

What is supply chain analytics in big data?

Supply chain analytics in big data processes extensive, complex datasets from varied sources. Big data analytics enables deeper insights and more accurate predictions through the use of artificial intelligence and machine learning.

What is the difference between supply chain management and supply chain analytics?

Supply chain management focuses on planning, executing, and controlling supply chain operations, while supply chain analytics involves analyzing data to optimize these operations. Analytics makes those operations smarter by revealing what’s working, what’s not, and what to do next.