Customer Background

Tinsley Equipment Company LLC. is an organization based in Texas, USA, that offers bulk material handling equipment for a range of industries across the Americas.

Challenges

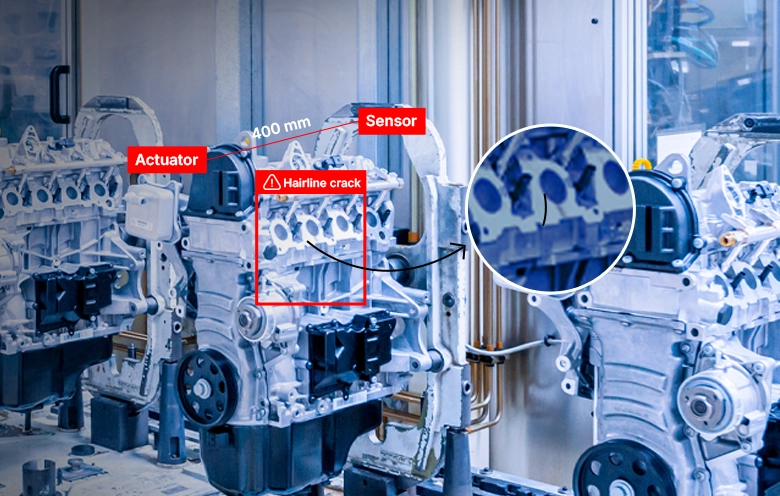

Tinsley offers a wide range of precision measurement products crafted according to their customers’ requirements. Often, it was a challenge for the sales and production teams to get accurate spatial information at the client’s location to provide an exact quote and rapidly close the deal.

The technicians needed a catalog to display their products to the customers. It was not feasible to physically showcase a variety of products with custom designs or the required dimensions. Customer retention was one of the crucial aspects that the company wanted to address. Tinsley was looking for innovative ways to present and test the products in their consumers’ environments.

Some of the key challenges included:

- Lack of correct measurements

- Time-consuming process of information sharing with the engineering and sales team

- Manual and repetitive process of quote generation

- Prolonged sales cycle

Solutions

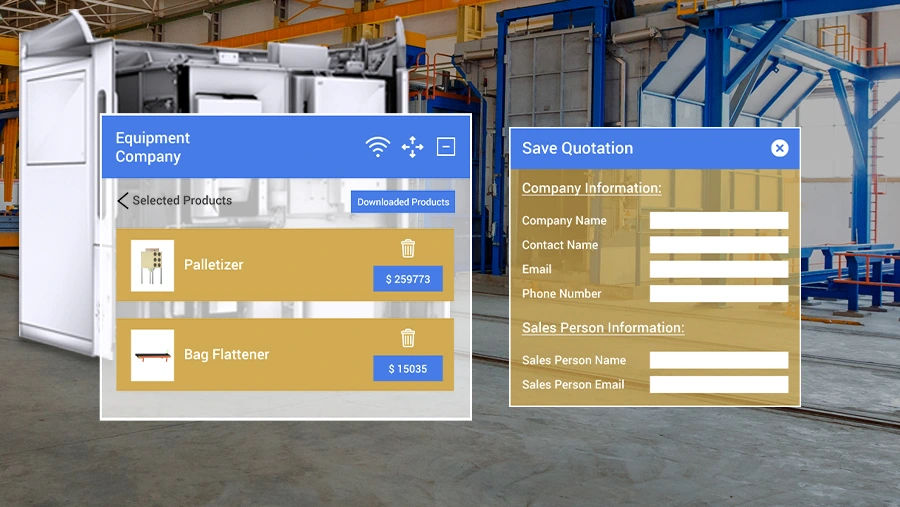

Softweb Solutions Augmented CPQ tool allows Tinsley to display products virtually from their catalog at the customer’s location. With augmented reality product visualization, the company can showcase its products in the form of interactive 3D holograms. This offers technicians a better sense of judgment on how the equipment will fit in the actual setting.

Tinsley’s users can get the look and feel of the product and how it can be integrated into their actual environment with our HoloLens app. Our MR solution also enables the sales team to share accurate quotes in real time, depending on the users’ requirements.

- Precise manufacturing: Technicians share accurate inputs with the sales and engineering team to provide tailored products to their clients

- Visual product configurator: Tinsley’s customers get seamless integration of physical objects in their virtual environment

- Value proposition: The company reduces the quote cycle by sharing information in real-time

- Quick sales closure: The sales team generates correct quotations to ensure faster deal closure

This MR solution has aided our customers to better understand crucial equipment details that drive price differences, allowing them to either move forward with the project or table it until another time. This is a great service to save time and has helped Tinsley develop a reputation of transparency and honesty that, we are told, many customers haven’t seen in some time.

– Warren Ferguson President at Tinsley Process Equipment

Dashboard

-

Industry

-

Technologies / Platforms / Frameworks

Unity3D, HoloLens 1, HoloLens 2, .Net, Node.js

-

Benefits

- Accurate measurements of equipment

- Faster quote generation

- Visual product cataloging

- Accelerated sales cycle

- Tailored manufacturing

- 3D visualization of products

- Improved customer satisfaction

- Reduced time for quote approval

Decades of Trust & Experience

1630+

Projects

545+

Technocrats

26+

Products and Solutions

1020+

Customers

Similar Case Studies

Enhanced quality control system for a manufacturing company with machine learning

Streamlined invoice reminder processes with RPA for a leading manufacturing company

Transforming battery management with IoT-powered insights

Connect Now

Our experts would be eager to hear you.