What do you want to place when you sell mattresses online? Perhaps everything, from the type of mattress, the number of layers, specific construction details, size and dimensions, special features, warranty details, certifications, and more. Let’s suppose you are a retailer with 3,000+ mattresses to sell online. Each mattress will require at least 20 product attributes, excluding the need to put photos and videos. This is where Product Information Management (PIM) shines, managing this extensive product data with efficiency and effectiveness.

And that’s the problem Beter Bed Holding, a Dutch company active in the European bedroom furnishings market, faced in 2011. When the company decided to go online, it had 1,205 stores across Europe. They implemented a product information management system to make BeterBed.nl live and manage its content effectively.

De Bijenkorf, the premium department store in the Netherlands, implemented product information management solutions to sell their 40,000 products with 110,000 variants online. With the implementation of a PIM system, CRH, an international leader in building materials, aimed to sell three million products online, up from 152,000. The list is endless, from The Fabory Group, Coca-Cola HBC, Nikon, PKZ, to Thomas Cook, and many more have implemented a PIM system.

When it comes to managing a large volume of product information in a valuable, accurate, and up-to-date manner, companies turn to a dedicated PIM system. This system ensures the accuracy and timeliness of product information and opens a world of possibilities for businesses. In this blog post, we will delve into what product information management is, the advantages of implementing a PIM, how it works, PIM use cases, and when you should consider seeking professional help.

What is a Product Information Management (PIM) system?

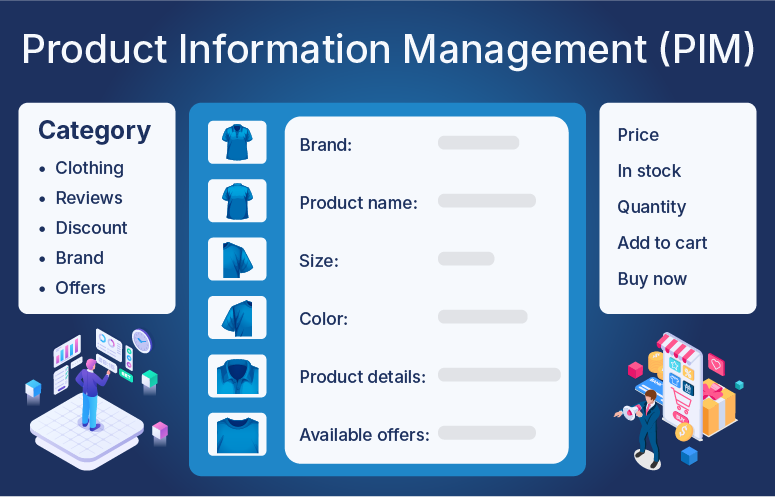

Product Information Management (PIM) is the process of managing all the product data required to market and sell products through distribution channels. Managing product data includes collecting, enriching, and distributing product information. This product data can be anything from technical specifications and compelling descriptions to high-quality images, videos, and multilingual translations. An internal organization creates product information to support a multichannel marketing strategy.

For example, if you want to sell clothes online. For that, you will need to have the following product attributes, as well as others.

Depending on the product, there may be additional information involved. And if the product has variations, such as different sizes, colors, or models, then multiply that information by the number of variations. This situation is exactly where PIM helps.

Advantages of implementing a PIM

Today’s consumers don’t settle for the first option they find. They compare, evaluate, and browse across platforms, often starting their journey on marketplaces like Amazon, as noted by Statista. In this environment, consistent and accurate product information is helpful and critical. Product Information Management (PIM) solutions help ensure consistency while driving operational improvements with the following advantages.

Less manual work, more efficiency

PIM systems reduce the need for repetitive data entry by automatically importing product details from internal and external sources. They also synchronize updates across all your sales platforms, minimizing errors and keeping information up to date.

Reliable, up-to-date product details

By pulling information directly from supplier systems, a PIM ensures that your product listings remain accurate. This enhances buyer confidence, resulting in fewer returns and fewer support issues.

A single source of truth

All product information lives in one central location. Whether it’s your website, mobile app, or third-party marketplace, every channel pulls data from this master database, maintaining consistency across the company regardless of the locations of your stores.

Easier growth and scale

As your product lines expand, a PIM eliminates the chaos of managing data in multiple spreadsheets or platforms. It ensures that every new item is published accurately across all channels, enabling smoother and faster scaling.

Stronger omnichannel presence

A PIM supports omnichannel strategies by allowing you to distribute content to multiple platforms, marketplaces, social media, apps, and more, without duplicating effort. This ensures a consistent brand voice across all customer interactions.

Smarter, faster marketing

Marketing teams gain immediate access to the latest product data from a centralized platform. This enables them to plan, personalize, and execute campaigns more efficiently and accurately across all channels.

If your organization is already using Salesforce for sales or marketing, early engagement with Salesforce consulting services can help align your PIM implementation with existing business workflows.

Product information management use cases

Use case 1: Large product catalog management

Fabory Group – International fastener wholesaler with 1,700 experts spread across 140 locations in 15 countries. Their product range includes over 96,000 SKUs of fasteners, tools, and industrial supplies.

Why a PIM system?

Fabory’s massive product catalog necessitated robust product data management capabilities. With 50,000 fasteners, 30,000 tools, 10,000 industrial supplies, and 6,000 safety products, their legacy system was unable to export data to their website efficiently. The complexity increased with the introduction of different supplier specifications, which required data standardization. As a specialist in fastening solutions, Fabory recognized the need for a reliable, detailed product data system where ‘details make a difference’ for customer decision-making.

The PIM process

Fabory developed a custom PIM system comprising 91,000 SKUs across over 3,000 product categories. They maintain 15-20 attributes per SKU in nine languages, adding 10,000 new articles annually while archiving 2,000 existing ones.

Automated processes after PIM implementation

- Data standardization: Previously, standardizing supplier specifications required 2-3 days of manual work per supplier catalog. Now, the PIM system automatically normalizes data formats, reducing the processing time to minutes.

- Multi-channel distribution: Previously, manual content distribution to print catalogs via Framemaker and e-commerce through Hybris took 1-2 weeks per channel. The automated system now distributes enriched content simultaneously across all channels in real time.

- Category management: Creating multiple categorizations (alphabetical for print and popularity-based for online) manually required 40+ hours per catalog update. The PIM system now generates these automatically based on predefined rules.

PIM benefits

The system enabled Fabory’s long-tail strategy while maintaining its reputation for providing reliable and fast data on fasteners. Quantified improvements include:

- Data consistency: Error rates dropped from 15% to under 2% across all channels.

- Content publication speed: Time-to-market for new products decreased from 3-4 weeks to 2-3 days.

- Operational efficiency: The content management team was reduced from 12 to 6 people while handling 50% more SKUs.

- Customer satisfaction: Product search accuracy improved by 40%, leading to 25% higher conversion rates.

Transformation summary

| Metric | Before PIM | After PIM | Improvement |

|---|---|---|---|

| Data standardization time | 2-3 days per supplier | Minutes | 99% reduction |

| Multi-channel distribution | 1-2 weeks | Real-time | Instant |

| Error rates | 15% | <2% | 87% reduction |

| Time-to-market | 3-4 weeks | 2-3 days | 90% reduction |

| Team size needed | 12 people | 6 people | 50% reduction |

Use case 2: Multichannel commerce integration

The Look/PKZ – Leading Swiss fashion retailer with 200+ million CHF turnover, 700 employees, and 50 stores across four retail brands (PKZ, Feldpausch, Blue Dog, Burger).

Why a PIM system?

PKZ recognized the younger generations’ shift to online fashion inspiration and developed an omnichannel strategy. Instead of creating separate brand websites, they launched “The Look” as an overarching platform encompassing loyalty programs, Switzerland’s largest fashion magazine, and multichannel shopping experiences. Their custom ERP system contained master data but wasn’t suitable for the rich product content needed across web, mobile, and social channels.

The PIM process

The PIM system manages 13,000-15,000 SKUs with 4,000-5,000 new products each season. A dedicated team comprises four content specialists for data entry and German-to-French translation, as well as seven photo production staff.

Automated processes after PIM implementation

- Photo shoot planning: The innovative photo shoot cockpit automatically plans entire photography processes and calculates optimal shooting sequences. Previously, manual planning required 8-12 hours per shoot and often resulted in suboptimal clothing changes. Now, the system reduces planning time to 30 minutes while optimizing the entire production workflow.

- Product publishing: New products can now be published within three days of arrival, compared to the previous 2-3 week manual process that required separate data entry for each channel.

- Brand consistency: Automated templates ensure consistent presentation across all channels, eliminating the 20+ hours spent weekly on manual formatting adjustments.

PIM benefits

PKZ’s PIM system transformed their operational efficiency with measurable results:

- Time-to-market: Reduced from 2-3 weeks to 3 days.

- Production cost per image: Decreased from CHF 45 to CHF 18.

- Photo shoot efficiency: Increased output by 200% while reducing production time by 40%.

- Content consistency: All departments, including marketing, logistics, sales, local sales offices, finance, e-commerce, and more, view the same content across channels, regardless of the store location.

- Revenue impact: Enabled selling “looks” rather than individual items, increasing average order value by 35%.

Transformation summary

| Metric | Before PIM | After PIM | Improvement |

|---|---|---|---|

| Time-to-market | 2-3 weeks | 3 days | 90% reduction |

| Production cost per image | CHF 45 | CHF 18 | 60% reduction |

| Photo shoot planning time | 8-12 hours | 30 minutes | 95% reduction |

| Brand consistency violations | 20+ per week | 1-2 per month | 95% reduction |

| Average order value | Baseline | +35% | 35% increase |

Use case 3: Business growth enablement

CRH Construction Materials – International building materials leader with 76,000 employees across 3,600 locations in 34 countries, market leader in Dutch construction materials.

Why a PIM System?

CRH’s decision to build B2B and B2C e-commerce platforms demanded robust product information management. Starting with 152,000 products, they planned aggressive growth to three million products through supplier assortment imports. The scale required systematic PIM capabilities to manage diverse building materials from multiple suppliers while maintaining data quality standards.

CRH sells products per item, pallet, or truck

The PIM process

The system integrates three data sources: external providers for base/enriched data, ERP systems for pricing/inventory, and ETIM for classification. CRH chose ETIM for quick and free implementation of their product data model.

Automated processes after PIM implementation

- Product classification: Manual ETIM classification previously required 30-45 minutes per product by technical experts. The automated system now classifies 80% of products instantly using pattern recognition, requiring human intervention only for complex or new product types.

- Supplier data integration: Previously, importing supplier catalogs took 2-3 weeks of manual data mapping and validation per supplier. The automated system now processes standard supplier feeds in 2-4 hours with 95% accuracy.

- Multi-channel categorization: Creating separate B2B and B2C categories manually required 60+ hours per product line. Automated ERP-to-web category mapping now handles this in minutes.

PIM benefits

CRH’s PIM system delivered substantial business value through operational improvements:

- Product catalog growth: Successfully scaled from 152,000 to 3+ million products while collecting 35 attributes per product, ahead of schedule. A phenomenal achievement.

- Supplier integration speed: Reduced from 2-3 weeks to 2-4 hours per supplier. CRH has over 700 suppliers.

- Data quality improvement: Now, there is no duplicate, incomplete, inconsistent, inaccurate, incomprehensible, non-conform, or not structured data entry.

- Revenue generation: Enabled complete supplier assortment sales, generating 40% additional revenue with existing customers.

- Operational efficiency: Reduced product research time for employees from 20 minutes to 2 minutes per customer inquiry.

Transformation summary

| Metric | Before PIM | After PIM | Improvement |

|---|---|---|---|

| Product catalog size | 152,000 | 3+ million | 20x growth |

| Supplier integration time | 2-3 weeks | 2-4 hours | 95% reduction |

| Data accuracy | 70% | 94% | 24% improvement |

| Product research time | 20 minutes | 2 minutes | 90% reduction |

| Revenue with existing customers | Baseline | +40% | 40% increase |

Use case 4: Global expansion support

Nikon Europe – Market-leading imaging products manufacturer serving 35 European countries with comprehensive consumer and professional photography solutions.

Why a PIM system?

Nikon’s e-commerce strategy required serving consumers, wholesalers, retailers, and employees across 35 European countries. As a product manufacturer, technical specifications, images, and documentation are fundamental to sales success. The PIM system became essential for managing product lifecycles from concept to end-of-life while supporting multiple customer segments and regional requirements.

The PIM process

The system manages 1,300 active SKUs and 8,000 archived products, storing 20+ external and 30+ internal attributes per product. Product enrichment begins a year before launch with unique development IDs from Japan.

Automated processes after PIM implementation

- Content localization: Previously, translating and adapting content for 35 countries required 6-8 weeks per product launch with 15+ translators. The automated system, equipped with sophisticated fallback mechanisms, now handles initial translations in 2-3 days, requiring only quality review by subject matter experts.

- Product lifecycle management: Manual tracking of products from concept to end-of-life across 35 markets required 40+ hours weekly. Automated lifecycle management now tracks all stages with real-time updates and alerts.

- Catalog generation: Creating country-specific catalogs with unique prices and assortments manually took 3-4 weeks per country. Automated generation now produces all 35 country catalogs simultaneously in 4-6 hours.

PIM benefits

Nikon Europe’s centralized PIM approach delivered significant operational and strategic advantages:

- Market launch speed:

This is a global scenario for Nikon. When the product becomes available in SAP, different regions of Nikon – Europe, the Americas, China, Asia-Pacific, and Japan – begin product data enrichment.

- Translation costs: As Nikon Europe sells in 35 European countries, localization is key. Nikon Europe enriches the base information in English and then utilizes several translation agencies or, in some cases, native speakers to translate all the information into dozens of different languages in a cost-efficient manner.

- Catalog creation efficiency: Improved from 3-4 weeks per country to 4-6 hours for all countries.

- Data consistency: Achieved 98% consistency across all markets vs. less than 60% with manual processes, especially in Nikon Europe, due to language barriers.

- Customer experience: Unified brand experience resulted in 30% higher customer satisfaction scores.

Product data enrichment tasks include adding a uniform product name, product descriptions, commercial product attributes, including technical specifications, and mapping photos to specific products. That’s how Nikon creates master data using a PIM system.

Later, different countries from each region can apply their prices, promotions, assortments, and product attributes in their languages. This exercise brought down Nikon’s market launch speed from weeks to a couple of days worldwide.

Transformation summary

| Metric | Before PIM | After PIM | Improvement |

|---|---|---|---|

| Market launch time | 6-8 weeks | 2-3 days | 90% reduction |

| Translation costs | Baseline | -65% | 65% reduction |

| Catalog creation time | 3-4 weeks/country | 4-6 hours (all countries) | 99% reduction |

| Data consistency | 60% | 98% | 38% improvement |

| Customer satisfaction | Baseline | +30% | 30% increase |

Use case 5: Omnichannel experience enhancement

Thomas Cook – Global travel organization with 12 billion € sales, 22.3 million customers, 31,000 employees, and 3,400 travel stores worldwide.

Why a PIM system?

Thomas Cook West Europe recognized product content as crucial for selling holidays across online, print, and in-store channels. Information accuracy prevents customer disappointment, while proper presentation conveys the destination experience. The system needed to manage massive data volumes, including basic hotel information, multilevel facilities, photos, videos, maps, and customer reviews to match promised experiences with reality.

The PIM process

The Stibo PIM system manages 1,300 destinations and 12,000 accommodations worldwide. Information sources include booking systems, external content publishers, and accommodation owners themselves.

Automated processes after PIM implementation

- Improving the catalog creation process:

Every year, Thomas Cook West prints many different catalogs, each with an average of 250 pages, 17,500 pages in total. They used to design each catalog manually. In the past, this meant that each page had to be designed manually every year.

Now, product managers just need to define the product placement in a simple format:

1. Hotel A – 25 % Page

2. Hotel B – 75 % Page

3. Hotel C – 200 %According to the instructions, the system automatically selects the correct template and pulls data from the PIM system. Hotels A and B will share a page, while Hotel C will have two pages. No manual effort is needed. This automation drastically reduces workload and ensures accurate, prioritized content. Competitors still rely on 10–15 designers for the same output.

- Content change management: The manual tracking of facility changes (like pool renovations) across 12,000 accommodations required 5-6 full-time staff. Automated workflows now immediately notify relevant parties about any changes that affect customer bookings.

- Multi-channel content distribution: Distributing content updates across online, print, and in-store channels manually took 2-3 weeks per update. Automated distribution now synchronizes all channels in real-time.

PIM benefits

Thomas Cook’s PIM system revolutionized their content operations and customer experience:

- Design efficiency: Reduced the design team from 10-15 to 1 designer while improving output quality.

- Catalog production time: Decreased from 6-8 weeks to a few hours.

- Customer complaints: Reduced customer complaints by 70%.

- Content accuracy: Improved from 80% to 96% across all channels.

- Operational cost savings: Reduced content production costs by 60%.

Transformation summary

| Metric | Before PIM | After PIM | Improvement |

|---|---|---|---|

| Design team size | 10-15 designers | 1 designer | 90% reduction |

| Catalog production time | 6-8 weeks | A couple of hours | 99% reduction |

| Customer complaints | Baseline | -70% | 70% reduction |

| Content accuracy | 80% | 96% | 16% improvement |

| Content production costs | Baseline | -60% | 60% reduction |

Use case 6: Rapidly changing consumer demand

Manor – Switzerland’s leading department store chain with 60% market share, 65 stores, CHF 2.87 billion turnover, and 11,000 employees.

Why a PIM system?

Manor’s 2009 web shop development required managing over 200,000 online SKUs, including 140,000 fashion items changing annually. The existing ERP system lacked user-friendliness and key PIM capabilities, resulting in slow product turnover. With 50,000 new items added yearly, Manor needed specialized PIM functionality rather than custom-building into their ERP system.

The PIM process

The system integrates base information from ERP and logistics partners, automatically managing product lifecycle from “online declaration” to zero-stock removal. Product enrichment varies by category, such as fashion items may have five attributes while multimedia products require 20 or more.

Automated processes after PIM implementation

- Product lifecycle management: Previously, manually tracking 50,000 new items yearly from arrival to removal required 3-4 full-time employees. The automated system now manages the entire lifecycle with minimal human intervention, triggering alerts only for exceptions.

- Seasonal inventory turnover: Managing 140,000 fashion items changing annually previously required 6-8 weeks of manual updates per season. Automated seasonal transitions now complete in 2-3 days with 99% accuracy.

- Multilingual content management: Creating content in German, French, and Italian manually required 4-6 weeks per product line. Automated translation and localization handle initial content in 1-2 days, requiring only quality review.

PIM benefits

Manor’s PIM implementation delivered substantial improvements in fashion retail operations:

- Product processing speed: New item processing time reduced from 3 days to 2-3 hours.

- Seasonal transition efficiency: Improved from 6-8 weeks to 2-3 days.

- Staff productivity: Reduced the content management team from 8 to 3 people while handling 50% more products.

- Inventory accuracy: Improved from 85% to 97% across all channels.

- Customer satisfaction: Faster product availability increased customer satisfaction by 25%.

Transformation summary

| Metric | Before PIM | After PIM | Improvement |

|---|---|---|---|

| Product processing time | 2-3 days | 2-3 hours | 90% reduction |

| Seasonal transition time | 6-8 weeks | 2-3 days | 95% reduction |

| Content management team | 8 people | 3 people | 62% reduction |

| Inventory accuracy | 85% | 97% | 12% improvement |

| Customer satisfaction | Baseline | +25% | 25% improvement |

Use case 7: Complex product relationships

Coca-Cola HBC Switzerland – Major non-alcoholic beverage industry player with 1,000 employees serving 60,000 customers, producing leading brands like Coca-Cola, Fanta, and Sprite.

Why a PIM system?

Coca-Cola HBC’s website replacement with the new e-commerce platform required better product information management. Despite managing only 300 products (adding 50 annually), they needed extensive product details and customer-specific assortments/pricing that their ERP system couldn’t support. Previous content quality issues necessitated resolution to improve the customer experience.

The PIM process

The eBusiness unit manages the PIM system, receiving master data from ERP, while marketing provides enriched, translated content. The system supports complex logistical calculations (weights, sizes, SKU types) with conversion rules for different units.

Automated processes after PIM implementation

- Customer web shop creation: Previously, creating customer-specific web shops required 6-8 weeks of manual setup, design, and configuration. The automated system now creates new customer portals with specific designs, assortments, and pricing in 2 weeks.

- Product lifecycle integration: The manual transfer of new products from the ERP, adding them to assortments, and deactivating discontinued items required 8-12 hours of work weekly. Automated integration now handles this seamlessly with real-time synchronization.

- Pricing and assortment management: Managing customer-specific pricing and assortments manually required 20-30 hours weekly per key account. Automated systems now handle this with rule-based pricing and instant updates.

PIM benefits

Despite initially modest expectations, Coca-Cola HBC’s PIM delivered significant business transformation:

- Customer adoption: 50% of customers now use online platforms compared to 0% before PIM.

- Order volume increase: Online customers order 7% more than traditional methods.

- Customer onboarding speed: Reduced from 6-8 weeks to 2 weeks.

- Operational cost savings: Reduced traditional offline channel costs by 30%.

- Customer satisfaction: Improved by 40% due to better product information and ordering convenience.

Transformation summary

| Metric | Before PIM | After PIM | Improvement |

|---|---|---|---|

| Customer web shop creation | 6-8 weeks | 2 weeks | 75% reduction |

| Online customer adoption | 0% | 50% | 50% adoption |

| Order volume (online vs offline) | Baseline | +7% | 7% increase |

| Offline channel costs | Baseline | -30% | 30% reduction |

| Customer satisfaction | Baseline | +40% | 40% increase |

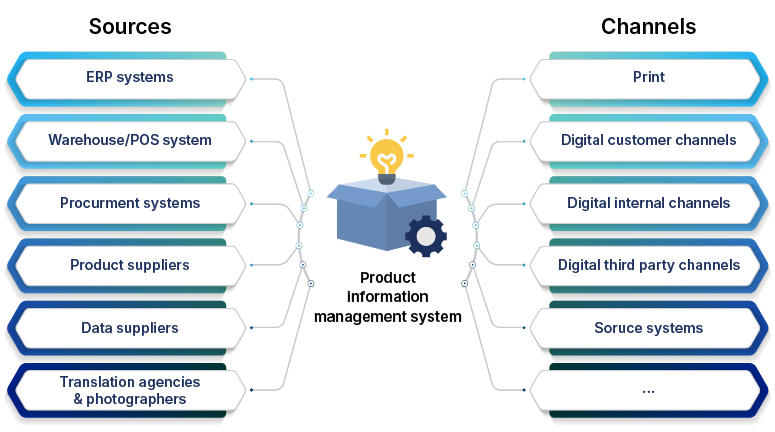

How does a PIM system work?

Modern PIM systems function as the central nervous system of the digital commerce ecosystem, managing data flows between enterprise resource planning systems, customer relationship management platforms, e-commerce engines, and marketing automation tools. This integration approach eliminates traditional data silos while maintaining the specialized functionality that each system provides.

The architectural foundation of PIM systems relies on APIs and microservices that enable real-time data synchronization across platforms. When product information is updated in the PIM system, automated workflows instantly propagate changes to all connected systems, ensuring consistency without manual intervention. This approach ensures consistency and scales seamlessly as organizations add new channels, expand into new markets, or acquire additional business units.

Leading PIM platforms now include pre-built connectors for popular e-commerce platforms, such as Shopify, Magento, and Salesforce Commerce Cloud, as well as enterprise systems from SAP, Oracle, and Microsoft. This connectivity enables organizations to implement PIM solutions without replacing existing technology investments. A PIM system enhances the value of current systems through improved data quality and consistency.

When should you consider getting professional help?

With professional help in PIM system implementation, a Product Information Manager will take care of your concerns about creating a master data, product data enrichment methods, data quality management, and most importantly, selecting and implementing a PIM system.

Additionally, product data specialists ensure that your data undergoes a seven-step cleansing process and meets the necessary quality standards to be considered qualitative data.

While implementing a PIM system, if your team faces challenges in setting up the following and more, you may consider getting professional help:

- Master data management

- Category management

- Classification and attribute management

- Unit management

- Catalog management

- Data quality management

- Product lifecycle management

- Publication management

- Product localization

- Authorization management

- PIM 2 Print support

- Media asset management

- Workflow management

- Price management

- Product enrichment

- Mass mutations and rollback

Furthermore, our consultants can help you understand how a PIM system can support the creation of product relationships and how these relationships can be utilized for various purposes, such as displaying similar products, up-selling more expensive products, cross-selling related accessories, and more. This is just one of the features of a PIM system. There are over 40 such features of PIM that we can suggest, depending on your business use case.

FAQs

1. How can PIM improve your product data across multiple sales channels?

PIM systems create a single source of truth for product information, which means a centralized repository where all product data is stored and managed. This single source of truth is then used to automatically format and distribute data to meet the specific requirements of each channel. This automation ensures consistent, accurate information across your website, marketplaces, mobile apps, and partner channels while reducing manual updating efforts by up to 80%.

2. How does a PIM help with launching products faster in new markets?

PIM streamlines global launches through automated localization workflows, multi-language content management, and region-specific attribute handling. By eliminating manual translation and reformatting bottlenecks, organizations typically reduce their market entry timeline from months to weeks, enabling them to launch products with speed and agility.

3. Can PIM integrate with existing tools like ERP, CRM, or Shopify/Magento?

Yes, modern PIM systems are designed for seamless integration with enterprise systems through APIs, webhooks, and pre-built connectors. They commonly integrate with ERP systems for inventory and pricing, CRM for customer data, and e-commerce platforms like Shopify and Magento for product catalog management.

4. How does PIM support personalized marketing or AI-driven product recommendations?

PIM provides rich, structured product data, which includes detailed product attributes, relationships, and metadata. This data is what personalization engines require to deliver targeted experiences. By maintaining this detailed product data, PIM enables AI systems to understand product characteristics and suggest relevant items based on customer behavior and preferences.

5. Is PIM only for large enterprises, or can SMBs benefit too?

While large enterprises were early adopters, cloud-based PIM solutions now offer scalable options for small and medium businesses. SMBs benefit from reduced operational costs, improved data accuracy, and the ability to compete effectively across multiple channels. This showcases the adaptability and versatility of PIM solutions, making them suitable for businesses of all sizes.

6. What should you look for when choosing a PIM platform?

Key evaluation criteria include integration capabilities with your existing tech stack, scalability to support growth, user-friendly interfaces for non-technical team members, AI-powered features for automation, robust data governance controls, and vendor support for implementation and ongoing optimization. Consider starting with a pilot project to evaluate platform fit before full deployment.