Every minute of unanticipated machine failure means lost revenue, delayed deliveries, and reduced customer trust. Traditional methods of maintenance lead to delayed issue resolution or wastage of resources on unnecessary repairs. This is where predictive maintenance is making a difference in the manufacturing industry.

By integrating AI, IoT sensors, and advanced analytics for predictive maintenance, manufacturers can now detect potential failures before they occur and act at the right time. This would result in smarter factories and lesser downtime.

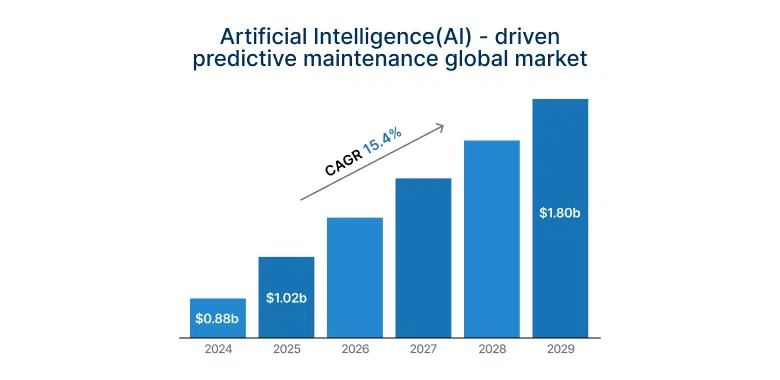

Leaders are adopting AI for predictive maintenance in manufacturing to reduce costs, improve efficiency, and gain a competitive edge. As more predictive maintenance companies bring innovative solutions to market, this approach is quickly becoming a cornerstone of industrial predictive maintenance strategies worldwide.

What is Predictive Maintenance (PdM)?

It is a proactive strategy that utilizes the latest technologies, such as AI, computer vision, data analytics, and other machine learning algorithms, to monitor equipment condition in real-time and forecast equipment failures. This technology helps the manufacturing industry to anticipate and avoid equipment failures, significantly enhancing operational efficiency.

PdM integrates information on hardware, software, and services to establish the maintenance needs for mechanical assets. Predictive maintenance discovers emerging failures, forecasts capacity overruns, detects breakdowns, and estimates remaining asset life. Organizations sometimes use AIOps (Artificial Intelligence for IT Operations) to support predictive maintenance.

Failure anticipation and preparation have been a reality of mechanical operations for centuries. Until now, the most common way to prevent part failure was to replace it at fixed intervals. This type of scheduled preventive maintenance is beneficial.

However, not all parts are prone to failure at the same rate, and premature replacement is wasted on an average approximation basis. In addition, a system based solely on scheduled maintenance will not detect early signs of failure in a part that becomes faulty ahead of time. Another approach to minimizing downtime was to replace all the parts whenever one failed, and no one knew which one, but this approach has a definite high-cost drawback.

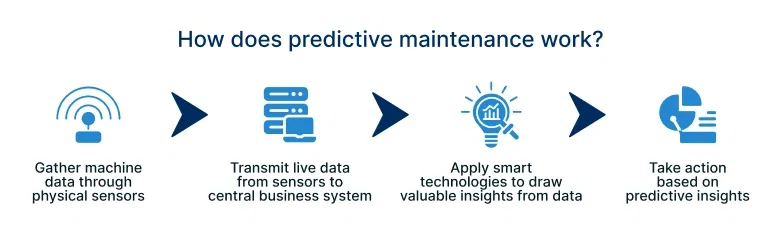

How does predictive maintenance work?

Predictive maintenance depends upon a range of technologies such as the Internet of Things (IoT), predictive analytics, and Artificial Intelligence (AI). Sensors collect data from assets like equipment and machinery. It is stored either at the edge or in the cloud in an AI-facilitated Enterprise Asset Management (EAM) or Computerized Maintenance Management System (CMMS). Machine learning and AI are employed to examine the data in real time to generate a picture of the equipment’s current state. Subsequently, it sends an alert to the maintenance team, if any probable defect is detected.

Predictive maintenance solutions can also predict the future equipment condition using machine learning algorithms. This increases efficiency in maintenance-related processes and workflows. For instance, just-in-time scheduling of work orders and labor and parts supply chains.

In addition, the greater the amount of data gathered, the higher the number of insights are created which help to make better predictions. This assures companies that equipment is operating at its best.

Common approaches of predictive maintenance in manufacturing

Every manufacturer’s transition to PdM looks a little different. From basic rules to advanced AI predictive maintenance software, the goal is always the same, finding the balance between effort and efficiency. The approach you choose depends on your business needs, scale, and resources.

-

Machine learning-driven predictive maintenance

Machine learning algorithms analyze patterns in past and real-time equipment data to make more accurate predictions about failure. In contrast to static thresholds, these kinds of algorithms learn and adapt to changing circumstances, picking up subtle warnings that suggest disruptions. For example, automotive companies use predictive analytics to forecast robotic arm failures in advance to prevent plant shutdowns.

Information from various sources is collected and analyzed through advanced analytics platforms which makes predictions more accurate. This adaptive solution helps in more intelligent decision-making and enhances maintenance effectiveness in dynamic manufacturing ecosystems.

-

Rule-based predictive maintenance

This technique involves applying pre-established limits for certain parameters, like vibration levels or operation temperatures, to trigger maintenance activities. It is appropriate for assets whose failure modes are well-known and whose conditions positively identify faults. For instance, food processing factories usually keep records of equipment temperature ranges to maintain hygiene and safety requirements.

These rules trigger alerts automatically when sensor readings surpass predefined thresholds. Though less complicated than machine learning models, rule-based approaches are an accessible launching point for facilities just starting to implement predictive maintenance technologies.

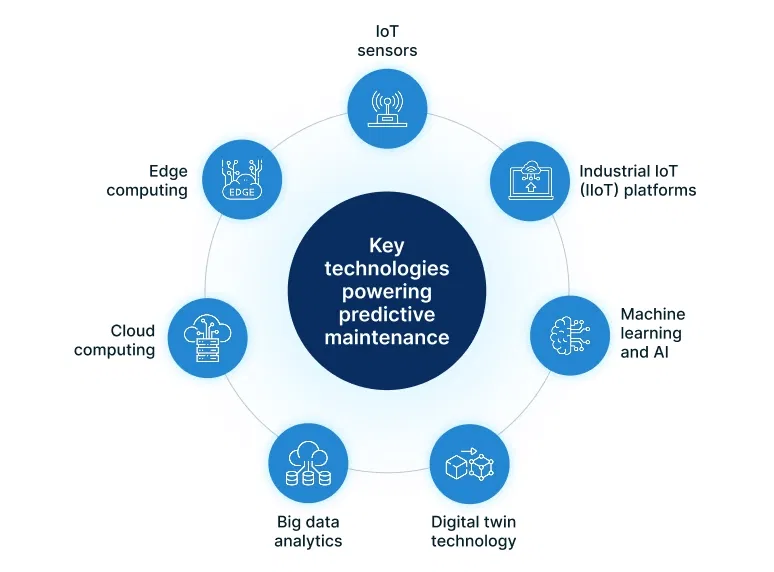

Key technologies powering predictive maintenance

Predictive maintenance in the manufacturing industry isn’t driven by one tool alone. It’s the combination of emerging technologies that makes it powerful. For manufacturers, the takeaway is simple: success lies in understanding how to connect these tools into a single, workable system.

-

IoT sensors

IoT sensors continuously monitor equipment conditions like temperature, vibration, and pressure. They provide the real-time data needed to detect minor issues before they turn into costly failures.

-

Industrial IoT (IIoT) platforms

IIoT platforms collect, connect, and manage sensor data across machines. They create a unified system where maintenance teams can monitor performance and respond quickly to warning signs.

-

Machine learning and AI

AI and machine learning analyze huge amounts of data to detect patterns and anticipate failures. These tools make maintenance smarter by learning from past performance and improving accuracy over time.

-

Digital twin technology

Digital twins create virtual models of physical assets, simulating real-world conditions. This helps teams test scenarios, predict wear, and plan maintenance without interrupting operations.

-

Big data analytics

Big data analytics converts unprocessed data from various sources into clear insights. It detects trends, identifies anomalies, and streamlines maintenance schedules for peak efficiency.

-

Cloud computing

Cloud computing makes predictive maintenance scalable and flexible. It enables secure storage, easy access to data, and powerful analysis tools without hefty investment in on-site infrastructure.

-

Edge computing

Edge computing processes data directly at the equipment site, reducing delays. It’s especially useful for remote or critical assets where fast decisions can prevent costly downtime.

Use cases of predictive maintenance in manufacturing with real-world example

Industrial predictive maintenance is already fixing real issues. By examining real-world use cases, manufacturers can identify areas to save downtime, eliminate waste, and enhance safety. These examples usually become a template for creating better operations.

-

Preventive asset maintenance

Companies rely on machinery and equipment to run production lines. Equipment breakdown may bring about downtime and increased costs. Predictive analytics helps discover patterns in machine behavior through the examination of usage history, temperature, and vibration. Maintenance can be scheduled as soon as failure signs appear, reducing downtime and extending machinery life.

For instance, Samsung’s pre-emptive asset management approach uses IIoT sensors, smartphones, and predictive analytics to monitor equipment condition in real time. It gathers asset information and monitors it in real-time for indications of wear. This helps to deal with assets proactively, minimizing downtime and enhancing asset lifespan.

-

Demand forecasting

Accurate demand forecasting is required to allow manufacturers to produce the correct products. Overproduction leads to increased inventory and waste, whereas underproduction implies lost sales. Predictive analytics examines prior history of sales, seasonal trends, as well as external factors like market trends in order to make improved demand forecasts.

For instance, Ford reported a loss in its electric vehicle division for Q1 2024 while the company was profitable overall. In response, the company improved its demand forecasting abilities. By leveraging predictive analytics to examine past data and market trends, Ford aimed to better forecast shifts in consumer demand toward EVs over gasoline vehicles. This approach is helping the company optimize production, reduce excess inventory, and align output more closely with market demand, driving greater efficiency and profitability.

-

Inventory control

Excess inventory ties up capital and incurs higher storage expenses, while inadequate inventory disrupts production and sales. Predictive analytics can improve inventory control by forecasting raw material and finished goods requirements.

By examining historical usage data and vendor lead times, manufacturers can anticipate when to restock material and decide the quantity accordingly.

For instance, Dell operates with a Build-to-Order (BTO) supply chain in which goods are gathered only after receiving orders. It minimizes the requirement to hold huge number of finished goods and provides greater manufacturing flexibility. Dell reduces surplus inventory and expenses by personalizing components and streamlining procurement. This helps Dell to respond fast to customers’ demands while maintaining an effective and cost-efficient production process. This leads to higher profitability and optimized supply chains.

-

Spend forecasting

Predictive analysis can be applied to physical operations as well as help manufacturers manage their finances more effectively. Spend forecasting uses historical information regarding spending like raw materials, wages, and equipment maintenance to forecast future spending. This enables manufacturers to plan better and locate areas where cost-reduction activities can be applied.

For example, Coca-Cola uses predictive analytics in forecasting spends by analyzing a range of variables including weather, crops’ harvests, prices, and demand patterns. This helps them enhance their procurement decisions of raw materials, e.g., oranges for making juices. By forecasting future cost and availability of ingredient, Coca-Cola simplifies its procurement processes and minimizes utilization of resources. This helps in saving money and efficient management of stock, ultimately leading to enhanced operational efficiency.

Top 7 benefits of predictive maintenance in manufacturing

When executed well, predictive maintenance in manufacturing becomes a strategic enabler of operational excellence. It fosters a culture of reliability, safety, and efficiency. The greatest advantage is that PdM provides manufacturers with confidence in equipment as well as transparency in decisions.

-

Reduced downtime

Unexpected downtime leads to interruption in production and workflow delays. This costs industrial manufacturers approximately $50 billion each year. PdM minimizes this by optimizing asset performance and detecting faults before they appear or increase in severity.

-

Improved productivity

Workplace productivity is improved by predictive maintenance solutions in a number of ways, including asset performance optimization, enabling manufacturers to plan the maintenance activity against times of lower demand, and facilitating quicker response to breakdowns. This also includes identification of fault areas, enabling targeted repairs and equipping employees and technicians with high-quality data to support informed maintenance decisions.

-

Better metrics

Better maintenance metrics are an important result of predictive maintenance. The most impactful of these include:

- Increased Overall Equipment Effectiveness (OEE)

- Increased Planned Maintenance Percentage (PMP)

- Decreased Mean Time To Repair (MTTR)

- Increased Mean Time Between Failures (MTBF)

-

Extended equipment lifespan

Constant condition monitoring, prompt alerts, and quick repairs and replacement improve the operation of industrial assets and their durability.

-

Decreased risk of accidents

Predictive maintenance reduces the likelihood of accidents caused by abrupt shutdowns, equipment failure, and engine malfunctions, providing safer working conditions.

-

Preventive maintenance planning

Predictive models utilizing sophisticated ML algorithms can properly predict when a machine is most likely to fail. This allows technical staff to schedule their maintenance operations, so they address the most critical ones first.

-

Cost savings

Fewer downtime hours, higher efficiency of operation, highest performing equipment, and fewer total repairs result in manufacturers realizing more savings in maintenance operations.

In addition, proactive maintenance methods drastically decrease the usage of power and maintenance materials such as filters, lubricants, and replacement parts, further lowering expenses.

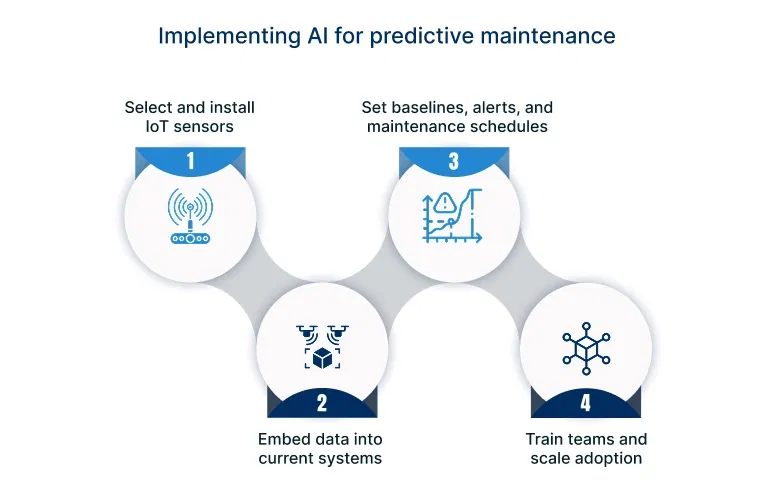

How to implement AI for predictive maintenance in your manufacturing business

Effective enabling of predictive maintenance for manufacturing requires a technology-enabled strategy combined with operational objectives. The below steps outline the essential technical considerations to guarantee your predictive maintenance solution provides accurate, actionable recommendations.

-

Select and install IoT sensors

Select sensors that measure physical parameters applicable to your equipment and types of failure. Common sensors are tri-axial accelerometers for vibration, infrared sensors for thermal variations, ultrasonic sensors for looseness or leaks, and acoustic sensors for crack detection.

Consider environmental conditions such as temperature, humidity, and electromagnetic interference while deploying sensors to prevent data noise. Employ industrial communication protocols such as MQTT (Message Queuing Telemetry Transport) or OPC-UA (Open Platform Communications – Unified Architecture) to maintain reliable, real-time data transfer.

Deploy edge computing nodes near sensors to preprocess data, filter out anomalies, and compress signals. This minimizes bandwidth utilization and latency before data is transmitted to central systems.

Use statistical failure analysis techniques like Weibull analysis to notify failure patterns. This information guides sensor selection and predictive model building.

-

Embed data into current systems

Smooth integration of sensor data into Computerized Maintenance Management Systems (CMMS) and Enterprise Resource Planning (ERP) is essential for efficient maintenance processes. Utilize APIs and middleware to interface multiple systems and automate work order generation initiated by predictive notifications.

Retrofitting technologies such as wireless sensor networks or protocol translators can be utilized for aging hardware. Legacy equipment can send data to new predictive maintenance systems without having to replace them at high expense.

Source: The business research company

-

Set baselines, alerts, and maintenance schedules

Develop adaptive performance baselines that reflect dynamic operating conditions using machine learning models. These models adapt thresholds according to equipment load, environmental conditions, and historical behavior. This enhances accuracy in detecting anomalies and minimizing false alarms.

Configure alert systems to grade issues in steps, from low-priority warnings to critical alarms requiring prompt action. Change maintenance schedules from fixed intervals to condition-based triggers. This maximizes resources and minimizes unnecessary downtime.

-

Train teams and scale adoption

Prioritize training in predictive analytics interpretation and sensor data quality assessment. Provide maintenance and operations teams with diagnostic tools that visualize trends and uncover root causes.

Foster collaboration between IT, data specialists, and maintenance engineers to resolve integration challenges and refine predictive models. Scalable adoption depends on consistent data practices and continuous feedback to improve system performance and ROI. When implemented effectively, predictive maintenance delivers measurable gains in uptime, cost efficiency, and asset longevity.

Things to consider before adopting PdM for manufacturing

Every new technology brings both opportunities and challenges. Before investing in predictive maintenance solutions, manufacturers should weigh the practical realities like cost, data quality, and team readiness. Taking a thoughtful approach ensures the shift to industrial predictive maintenance is sustainable and effective.

-

Data quality and collection

High-quality, consistent data is the foundation of any good predictive maintenance program.

Data availability and integration: Evaluate what data you currently gather from your equipment and whether it is adequate to develop good predictive models. Think about whether new or supplemental IoT sensors on current equipment are necessary, particularly for older equipment that does not have native data gathering capability.

Data infrastructure: You will need an infrastructure to cost-effectively gather, store, and process vast amounts of real-time and historical sensor data. This can involve investments in a data pipeline, and cloud or edge computing, to reduce latency.

Data quality and integrity: Inaccurate or unreliable data can result in poor predictions and false alarms, making the system ineffective. You will need to implement processes for validation and cleaning of the data.

-

Initial investment and Return on Investment (ROI)

PdM provides immense long-term savings, the initial investment is a little high and demands a strong business case.

Justify the investment: Carry out a cost-benefit analysis. The initial investment is in sensors, software, system integration, and training employees. These must be balanced against possible long-term gains such as minimized unplanned downtime, lower emergency repair costs, longer asset life, and streamlined spare parts inventory.

Financial planning: While a 10x ROI is theoretically possible, the actual return will vary based on the unique setup and requirements of your facility. You should create a realistic budget and monitor performance metrics to prove concrete value to stakeholders.

Beginning with a pilot program: To reduce risk, most companies start with a small pilot program on one or two key assets. A well-performing pilot can establish a compelling business case for taking the program companywide.

-

Skills and training of the workforce

A successful transition to predictive maintenance necessitates an extensive change in culture and investment in your workforce’s abilities.

Upskilling the employees: Your maintenance staff will require training to read data and address system alarms. This entails building skills in data analytics, machine learning, and IoT technologies.

Tackling resistance to change: Staff may feel unsure of new technology so there must be a thorough change management program, including effective communication and involvement of staff in the process.

Building expertise: Companies might require specialized machine learning engineers and data scientists to be hired internally or third-party technology consulting firms to be engaged.

-

Prioritization and asset criticality

It is not practical or necessary to apply PdM to all equipment simultaneously. You need to target the most critical assets to get the maximum benefit out of it.

Identify key assets: Conduct an equipment criticality analysis to determine the machines whose failure would result in the highest disruption, cost, or risk to safety.

Prioritize deployment: Prioritize assets by their operating importance, history of failure, and repair costs. Begin your PdM program with the most critical equipment.

Choose the appropriate technology: The selection of condition monitoring methods, i.e., vibration analysis, thermal imaging, or oil analysis, needs to be optimized for the targeted failure modes of the high-priority assets.

-

Integration and scalability

PdM is not an isolated solution. It must be integrated with your current operating systems for optimum benefit.

System integration: Think about how the new PdM system will integrate with your current Enterprise Resource Planning (ERP) or Computerized Maintenance Management Systems (CMMS). Smooth data exchange between systems is essential for efficient operations.

Scalability: Select a solution that will scale with your company. The technology must be able to begin small and grow to more assets and facilities with time.

Long-term plan: Chart a continuing improvement loop. As your predictive models become increasingly accurate, you can grow the program by introducing increasingly complex tools such as digital twins and AI analytics to further optimize performance.

Build intelligence from the ground up with predictive maintenance

Manufacturing success depends largely on anticipating problems before they disrupt operations. Predictive maintenance in manufacturing enables factories to shift from reactive fixes to proactive performance, making innovation feel less like disruption and more like evolution.

By leveraging advanced technologies, manufacturers can build adaptive systems that detect faults early, reduce unplanned downtime, and keep production running smoothly. Beyond efficiency, predictive maintenance also supports sustainable growth, helping businesses reduce waste, optimize energy use, and extend equipment lifespan while maintaining peak performance.

Smarter factories are built with intelligent choices, and predictive maintenance is the first step to less downtime and greater success. Partnering with the right predictive maintenance companies ensures you realize the full potential of this approach, driving efficiency, improving sustainability, and securing a competitive edge.