When Toyota’s Georgetown plant discovered a hairline crack in an engine block that traditional quality control had missed, it affected 847,000 vehicles. It resulted in a $1.2 billion recall. Human eyes, no matter how trained they are, have limits. The defect would have been instantly detected by today’s AI-powered machine vision services.

The above example illustrates why manufacturing leaders turn to AI-powered machine vision to strengthen their quality processes. The pressure is real: higher quality demands, lower margins, and, as Toyota learned, even tiny defects can cause billion-dollar recalls. For manufacturers, the question is not whether to use machine vision, but how to make it a competitive advantage.

This blog post explores how AI machine vision works in manufacturing, why old methods are not sufficient, and what good implementation looks like. You will also understand why timing matters and how to determine if this technology aligns with your operations.

What is machine vision in manufacturing and how does it work?

Machine vision in manufacturing uses cameras, software, and automated decision-making systems that inspect, analyze, and guide production processes with superhuman precision. These systems capture sharp images and use math to detect patterns, measure dimensions, and find defects with consistent accuracy.

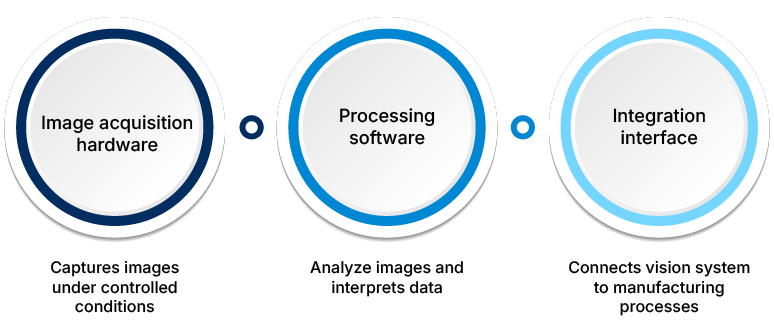

The working of machine vision in manufacturing involves three basic parts: cameras, processing software, and connections. Industrial cameras capture detailed product images under controlled lighting. Processing units analyze visual data using programmed rules or learned patterns. Connections then inform manufacturing systems of the results and trigger responses, accept, reject, or adjust the process.

Why traditional machine vision needs an upgrade

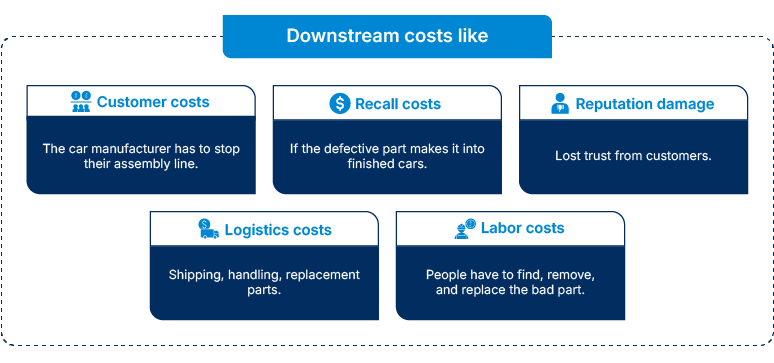

Manufacturing quality control faces a crisis. Despite decades of process improvement and Six Sigma methods, defect rates in complex manufacturing still average 3-5%, per a recent McKinsey survey. For a mid-sized auto supplier making 100,000 parts monthly, this means 3,000-5,000 defective parts enter the supply chain, each carrying huge downstream costs.

The traditional approach of human-led visual inspection, supplemented by basic machine vision systems, faces three insurmountable challenges.

The old approach of human visual inspection, helped by basic machine vision, faces three problems it cannot solve.

- First, human attention drops over time. Detection accuracy falls up to 25% after just two hours of continuous inspection.

- Second, modern manufacturing is complex. Microelectronics, composite materials, and precision assemblies require detection capabilities that exceed human senses and basic machine vision.

- Third, today’s production lines are fast. They outpace human response times.

That is precisely why traditional machine vision needs an upgrade.

The paradox grows when examining competition. Companies like Foxconn and Bosch report 99.7% quality rates using advanced AI vision systems, while their competitors, who use conventional methods, struggle to exceed 94%. In markets where a fraction of a percentage point of quality improvement can mean $100 million in avoided costs and a better reputation, this gap represents a competitive advantage.

Beyond old machine vision limits, labor markets worsen the challenge. Skilled quality inspectors are more expensive and harder to find and retain. The median age of manufacturing quality workers is 52. Thirty percent can retire within five years. Meanwhile, production gets more complex, demanding skills that training programs cannot supply fast enough.

Why manufacturing leaders bet big on AI-powered machine vision systems

They bet big because AI-powered machine vision systems deliver measurable improvements in manufacturing quality control through precision, speed, and intelligence. Three key factors contribute to this impact: enhanced defect detection accuracy, expensive change, and AI machine vision goes beyond catching bad parts.

Factor 1: Enhanced defect detection accuracy

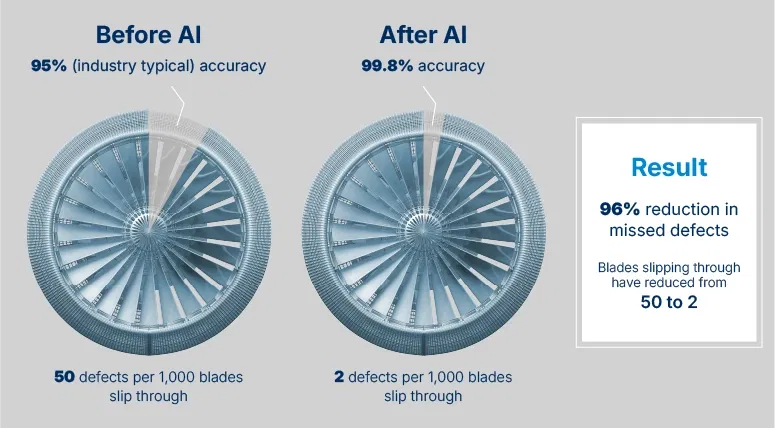

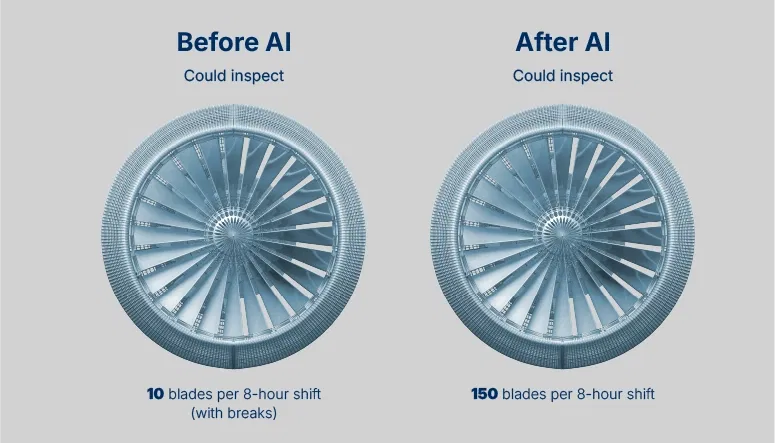

General Electric’s jet engine manufacturing facility in Cincinnati shows this. GE spent over $113 million upgrading its Cincinnati facilities. The company allocated a significant portion of the investment to AI-powered machine vision systems for turbine blade inspection.

What are turbine blades?

- Critical components in jet engines that spin at extremely high speeds (10,000+ RPM).

- Made from exotic materials and cost $10,000-50,000 each.

- A single defective blade can cause catastrophic engine failure in mid-flight.

Within two months, they saw transformative results:

1. 99.8% defect detection accuracy

Real-world impact:

- Dramatically reduced risk of engine failures

- Fewer warranty claims and recalls

- Enhanced safety reputation

2. Reduced inspection time from 45 minutes to just 3 minutes per blade.

Economic impact:

- Production throughput: 15x more blades inspected with the same labor.

- Labor cost per blade: Reduced by ~93%.

- Faster delivery: Engines ship weeks earlier.

Now, their system can identify even microscopic stress patterns. Ultimately, GE achieved substantial cost savings and significantly enhanced customer confidence.

The strategic impact with better defect detection accuracy

AI-powered machine vision is not just about detecting defects more effectively. It’s about (through GE’s example):

- Market positioning: GE can now claim industry-leading quality standards.

- Pricing power: Superior quality justifies premium pricing.

- Risk reduction: Lower insurance costs, fewer legal liabilities.

- Scalability: This system can be replicated across other GE facilities.

Factor 2: Change is expensive with traditional systems

Traditional machine vision: Traditional machine vision is like a specific robot that can only do one job. If you want to inspect red widgets that are 2 inches wide, you have to:

- Write detailed code telling it exactly what a “good” red widget looks like.

- Program precise measurements (exactly 2.00 inches wide, tolerance ±0.01).

- Define every possible defect type and how to detect it.

- Set lighting conditions, camera angles, and other elements.

What happens when you need to change products: Now imagine your factory needs to switch from red widgets to blue widgets that are 2.5 inches wide. With traditional systems, you essentially have to start over:

- Rewrite all the code for blue instead of red.

- Reprogram all measurements to 2.5 inches instead of 2.0.

- Redefine defect detection for the new shape/size.

- Recalibrate lighting and cameras.

This process can take weeks or months of programming.

The business impact: Bottlenecks

Traditional machine vision systems can create bottlenecks during design or material changes:

- Production can stop while engineers reprogram the vision system.

- New product launches can be delayed because quality systems are not ready.

- Material changes (switching suppliers, new materials) require extensive reprogramming.

- Seasonal products can become costly because you’re constantly reprogramming.

Example: A clothing manufacturer wants to switch from inspecting cotton shirts to polyester shirts. Traditional vision systems may require 4-6 weeks of reprogramming to accommodate the varying fabric textures, reflection properties, and defect types.

How AI changes the game

AI machine vision: Instead of programming specific rules, AI systems learn patterns from examples:

- Show it 10,000 photos of good red widgets and 1,000 photos of defective ones.

- The AI learns what “good” looks like without you writing specific code.

- It learns to recognize quality patterns, not just specific measurements.

When you need to change products: Switch from red widgets to blue widgets? With AI:

- Show examples of good and bad blue widgets

- The system learns new patterns in hours or days, not weeks.

- Much of its previous learning about “what makes a good widget” transfer over.

- Require minimal human programming.

Real-world example

BMW’s Spartanburg plant demonstrates this adaptability advantage perfectly. When introducing their iX electric vehicle line, traditional vision systems would have required 6-8 weeks of reprogramming for new component specs. Their AI machine vision infrastructure adapted within 48 hours, maintaining full production velocity during the transition.

The bottom line

- Traditional machine vision = Rigid and slow to change

- AI machine vision = Flexible and fast to adapt

This flexibility is crucial in modern manufacturing where companies need to rapidly introduce new products, switch materials, or adapt to customer demands.

Factor 3: Beyond just catching bad parts

Most people think machine vision is just about identifying defective products and disposing of them. However, this section explains how AI vision generates significantly greater economic value through prediction and optimization.

The three economic benefits

1. Optimize maintenance schedules

Traditional approach: Fix machines when they break or follow rigid schedules (such as changing oil every 3,000 miles, regardless of condition).

AI vision approach: The system notices subtle changes in product quality that indicate machine wear before failure occurs.

Example:

- AI notices that holes being drilled are getting slightly less precise over time.

- This pattern indicates the drill bit is worn out.

- Instead of waiting for the drill to break (causing downtime) or replacing bits on a fixed schedule (wasteful), you replace the bit exactly when needed.

- Result: Less downtime, lower maintenance costs, better product quality.

2. Reduce material waste

How it works: AI vision does not just say “this part is bad.” It says, “this part is bad AND here’s exactly why.”

Example:

- AI detects that plastic parts are coming out with slight warping.

- Analysis shows the warping happens when injection molding temperature exceeds 180°C.

- Factory adjusts the temperature control to stay below 180°C.

- Result: Fewer defective parts = less wasted plastic, less rework, higher yield.

3. Improve supplier relationships through better quality feedback

Traditional feedback: “Hey supplier, 5% of your parts are defective. Fix it.”

AI-powered feedback: “Your parts show micro-cracks when your furnace temperature exceeds 1,200°C on Tuesdays between 2-4 PM. This correlates with your operator shift change. Here’s the data pattern from over 6 months.”

Why this matters:

- Suppliers can fix root causes instead of guessing.

- Better parts mean fewer problems for the manufacturer.

- Stronger partnership leads to better pricing and priority treatment.

Real-world example

Ford’s Dearborn truck plant reports a 15% reduction in material costs through AI vision-guided process optimization.

Here is how it happened:

- Pattern detection: AI vision noticed that certain steel panels were being rejected for surface defects

- Root cause analysis: The system traced these defects back to two specific conditions. One, when the humidity was above 60%. Second, when a particular stamping press was used.

- Process optimization: Ford adjusted their processes based on these insights:

- Control humidity better

- Adjust stamping press settings

- Change material handling procedures

- Result: 15% fewer materials wasted = 15% cost reduction

The bigger economic picture

This creates a virtuous cycle:

- Better quality data → Better process control → Lower costs → More profit

- Better supplier relationships → Better pricing → Priority access to materials

- Predictive maintenance → Less downtime → Higher productivity → More revenue

The key insight: AI vision transforms from a cost center (just catching defects) into a profit center (optimizing entire operations and supply chains).

How does AI machine vision work?

The core architecture relies on three essential components: image capture equipment, analytical software, and system connectivity interfaces. Here, we will explore the impact of AI on machine vision systems.

The process begins with neural network training using vast datasets of both good and defective products. During this phase, the system develops sophisticated pattern recognition that extends beyond human-defined parameters. A pharmaceutical packaging line, for instance, might train the system using millions of tablet images. This enables it to identify obvious defects like cracks or discoloration, and subtle variations in texture or geometry that relate to manufacturing process problems.

Real-time operation transforms this training into actionable intelligence. High-resolution cameras capture product images at production speed, often 1,000+ frames per second, while AI processors analyze each image within milliseconds. The system does not simply approve or reject products. It provides detailed diagnostic information about detected problems, process drift indicators, and quality trend predictions.

Intel’s semiconductor fabrication facilities demonstrate this diagnostic capability’s value. Their AI vision systems don’t just identify defective wafers. They trace defects to specific process steps, equipment conditions, and material batches. This granular analysis enables engineers to address root causes rather than symptoms, resulting in a 40% improvement in overall process reliability.

The integration challenge concerns most manufacturing executives: How do AI vision systems interact with existing quality management infrastructure? Modern AI vision platforms integrate seamlessly with ERP systems, quality management software, and production control networks through standard industrial protocols.

Siemens’ approach at their Amberg electronics factory illustrates effective integration. AI vision data flows directly into their manufacturing execution system, automatically triggering process adjustments when quality trends indicate potential issues. The system maintains complete traceability, enabling rapid response when customers report quality concerns.

| Traditional Machine Vision | AI-Powered Machine Vision |

|---|---|

| Lower accuracy | Enhanced accuracy |

| Expensive and slow | Cost-effective and fast |

| Just catching bad parts | Beyond catching bad parts |

| 3–5% | <1% |

| Expensive and hard to maintain | Minimal human programming |

| Generic | Specific |

| Rigid schedules | Optimized schedules |

| Higher waste | Reduced waste |

| Basic feedback | Improved feedback |

| Rigid and slow to adapt | Flexible and fast to adapt |

| Cost center | Profit center |

Implementation success depends on three critical factors: data quality, organizational readiness, and phased deployment strategy. Manufacturers achieving the highest ROI typically begin with high-impact, contained applications, such as final assembly inspection, before expanding to comprehensive quality monitoring. This approach allows teams to develop expertise while demonstrating clear business value.

How to implement AI-powered machine vision in three phases?

What separates manufacturers who achieve transformational results from those who struggle with AI vision deployment? The strategic imperative for AI machine vision implementation has shifted from “whether” to “when” and “how.”

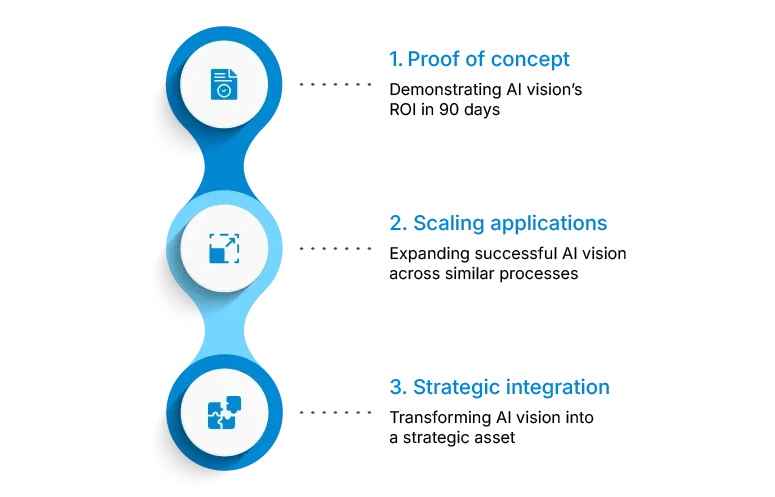

Successful implementation follows a structured three-phase approach that minimizes risk while maximizing learning.

Phase one: Develop a proof of concept

Phase one focuses on proof-of-concept applications where AI vision can demonstrate a clear ROI within 90 days. Critical component inspection, final product verification, or high-value assembly processes typically provide optimal starting points. The goal is not comprehensive coverage but rather establishing credibility and building internal expertise.

Johnson Controls’ HVAC manufacturing division exemplifies effective phase-one execution. They implemented AI vision for compressor housing inspection, achieving 99.5% defect detection accuracy while reducing inspection time by 70%. The $2.3 million investment delivered $8.7 million in first-year benefits through reduced rework, eliminated warranty claims, and improved production throughput.

Phase two: Expand AI vision applications

Phase two expands successful applications across similar processes while beginning integration with broader manufacturing systems. This phase typically spans 6-12 months and focuses on scaling proven approaches rather than experimenting with new applications. Organizations often realize their highest ROI during phase two as implementation efficiency improves and organizational resistance diminishes.

Phase three: Strategic integration

Phase three transforms AI vision from quality tools to strategic assets through predictive analytics and supply chain integration. At this maturity level, vision systems provide competitive intelligence about market quality trends, supplier performance patterns, and customer preference evolution. Caterpillar’s construction equipment division uses phase-three AI vision capabilities to optimize designs based on real-world quality performance data, reducing warranty costs by 22%.

Bonus tip: Organizational readiness and financial framework

The organizational readiness factor determines implementation success more than technology selection. Companies that achieve superior results typically establish cross-functional teams comprising representatives from operations, quality, IT, and finance. This structure ensures that AI vision implementation aligns with broader business objectives rather than remaining isolated within quality departments.

The financial framework for AI vision investment should reflect immediate cost avoidance and long-term competitive positioning value. Direct benefits, such as reduced defects, eliminated rework, and avoided recalls, typically justify investment within 12-18 months. Strategic benefits, like enhanced customer confidence, supplier relationship improvements, and market differentiation, provide sustained competitive advantage that compounds over time.

Why acting now matters

Market dynamics strongly favor immediate action. AI vision technology costs have declined significantly over the past three years while capability has increased exponentially. Cloud computing platforms now provide enterprise-grade AI processing power at accessible price points, eliminating traditional barriers to entry. Simultaneously, the talent pool for AI vision implementation has expanded, with major consulting firms and technology vendors offering comprehensive support services.

The competitive implications extend beyond immediate operational improvements. Companies implementing AI vision systems today are building valuable datasets and organizational capabilities that create sustainable advantages. Each day of production generates training data that improves system performance, creating a self-reinforcing cycle of quality enhancement.

Manufacturing executives who embrace AI-powered machine vision now position their organizations not just for current competitive challenges but for the intelligent manufacturing future that’s rapidly emerging.

The path forward is clear: AI-powered machine vision represents the next competitive frontier for manufacturing. The only question is whether your organization will define this future or be defined by it.