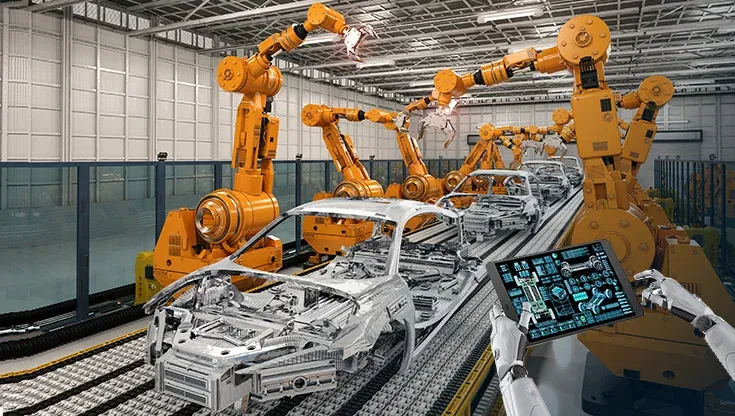

Production line monitoring solution

Track industrial products, monitor equipment, and analyze cycle times in real time. With AI-powered insights, the solution simplifies decision-making and drives operational excellence.

Automate your production line now!