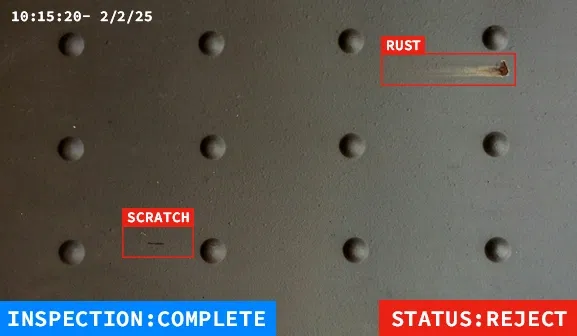

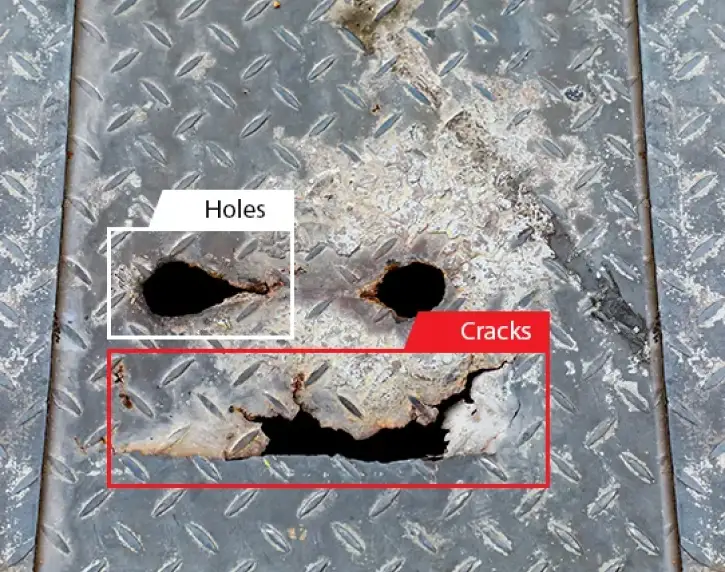

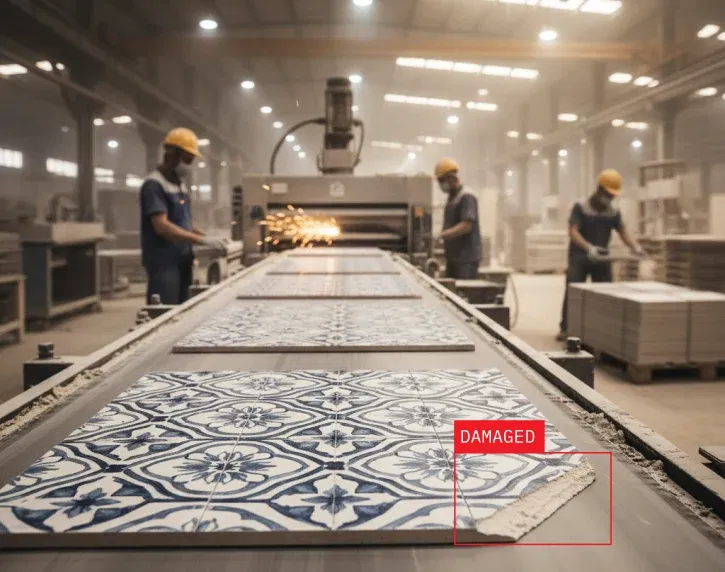

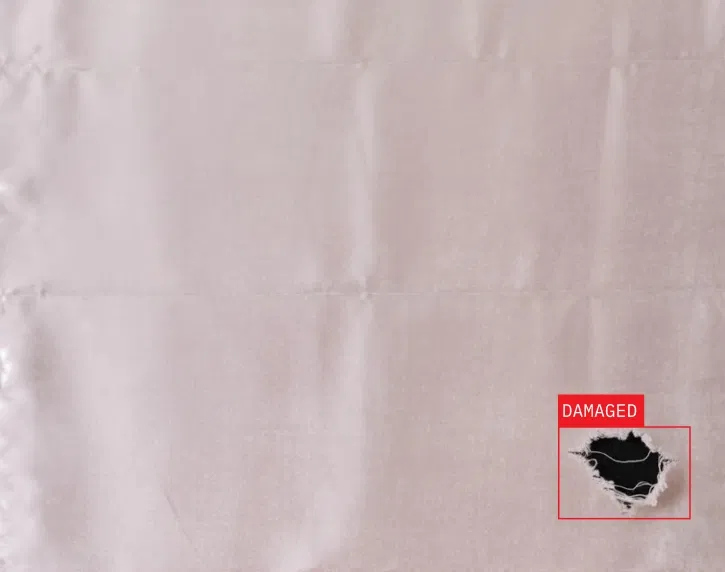

Eliminate defects and maximize quality control efficiency with automated surface inspection

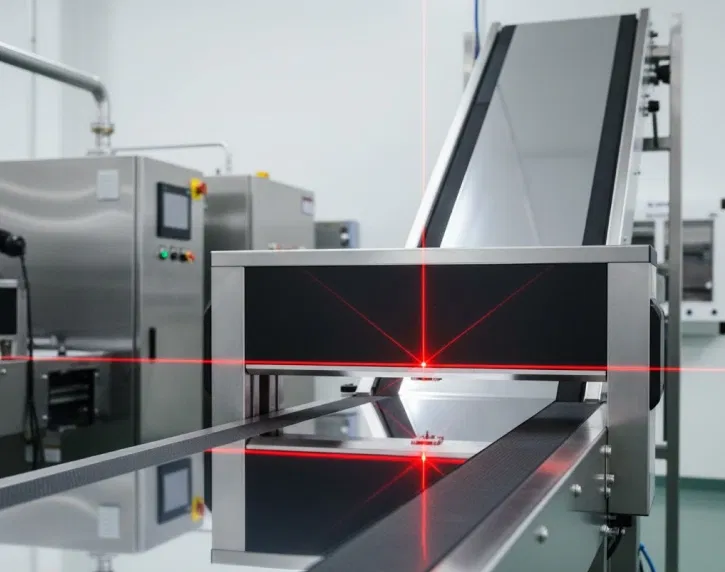

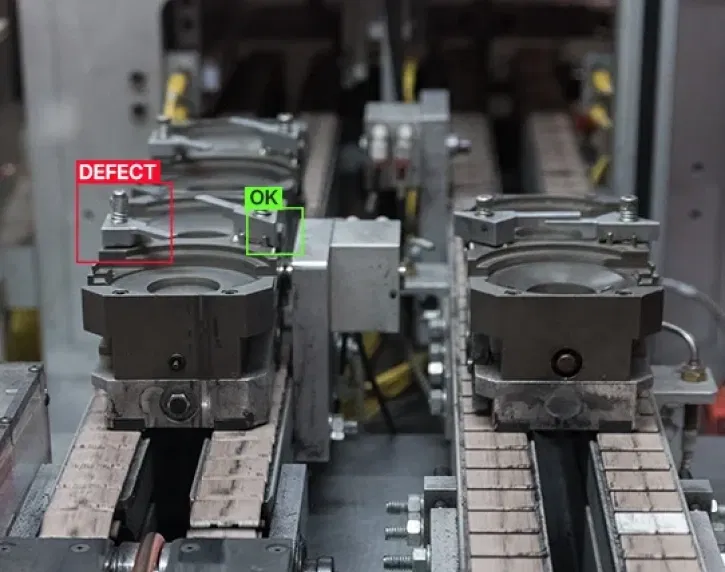

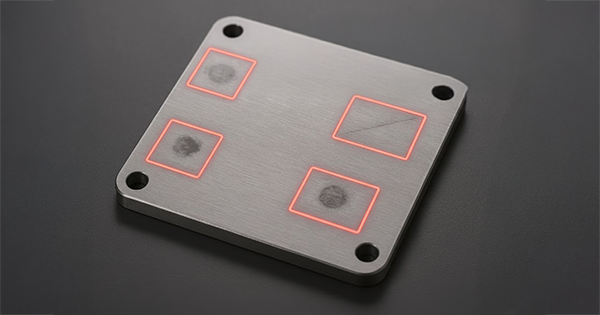

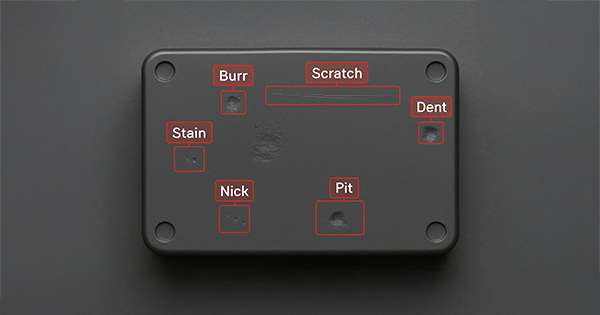

Every scratch, void, or surface irregularity, whether millimeter-sized or barely visible, threatens product integrity and customer satisfaction. Human inspection lacks the speed and precision to catch defects of all types and sizes reliably. Our AI-powered surface defect detection solution automatically identifies anomalies across materials, detecting defects as small as 0.1mm with 99%+ accuracy.

Softweb Solutions holds over 21 years of experience in delivering industrial automation, AI surface inspection solutions, and operational risk management. Using advanced computer vision and deep learning, our system automatically classifies and locates defects including corrosion, burrs, stains, and dimensional deviations. With proprietary algorithms trained in millions of defect images, we deliver faster inspections, reduced waste, and zero-defect quality assurance that protects your bottom line.