Supply chain automation solution

Automate more than half of your repetitive and predictable tasks within procurement, manufacturing, warehousing, and distribution

Share your requirementOur Clients

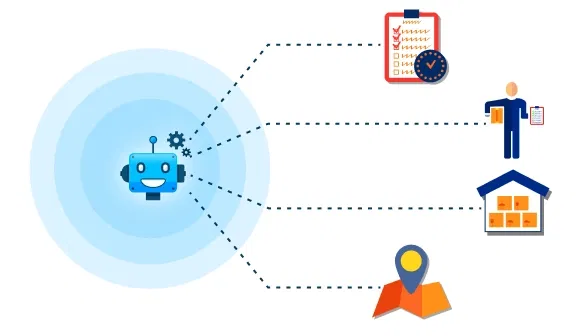

Many supply chains lose time and value because of manual workflows and disconnected processes. Our AI-driven automation solution handles repetitive, time-sensitive tasks that take up your team’s time. Here are a few examples:

For one of our clients in the USA, we developed a cloud-based platform to streamline planning, operations, reporting, and analytics. It helped them achieve a 52% increase in productivity, 100% data accessibility, and 85% improvement in warehouse visibility. Talk to our AI expert to learn how we can help you achieve your goals.

You can automate warehouse operations such as inventory tracking, stock movement, and order picking with supply chain optimization software. AI systems can automatically update stock levels, optimize picking routes, trigger replenishments, and much more so that you can speed up operations and avoid manual errors.

You can automate your entire quote management process, from configuration to pricing and quote generation. AI can validate configurations, calculate pricing instantly, and ensure that quotes reach customers within minutes. Additionally, it keeps sales and operations aligned.

You can automate order capture, validation, processing, and fulfilment. A robust supply chain automation helps set up a connected workflow from purchase to delivery. Its AI features help monitor every step, detect errors, route approvals automatically, and most importantly, give you a real-time view so that you can make faster decisions.

You can automate route planning, shipment tracking, and carrier selection using AI algorithms. They can analyze real-time variables such as traffic, weather, and delivery urgency. And the system can assign the best routes and transport modes to minimize cost and time.

You can automate the flow of materials, production schedules, and equipment performance. AI systems can analyze live data from machines and sensors and predict maintenance needs and balance workloads. They can help you adjust production plans in real time and run a more flexible and dependable operation.

You can automate supply chain data analysis and reporting and create a live, connected view of operations. AI can process data from procurement, production, and logistics in real time. And then, it can generate insights to identify performance trends, recurring challenges, and improvement areas.

20+

Years of expertise

1630+

Projects delivered

50+

Fortune customers

545+

Technology professionals

Our platform unifies manufacturing, logistics, and distribution operations data into a single system. It standardizes data formats and synchronizes updates. It also maintains a consistent record of all supply chain activities so that you can manage operations with accuracy and control.

Our platform monitors stock levels across warehouses and production sites. Using its AI models, your teams can predict demand and automate replenishment to maintain optimal inventory levels so that they can prevent stockouts or overstocks.

Our platform gives a live view of every operation, from sourcing to delivery processes. It provides real-time dashboards so that your teams can easily track supplier performance, order progress, shipment status, production flow, and much more.

Our platform uses AI to analyze real-time and historical data. It can identify patterns and trends across your supply chain and help you forecast customer demand, detect market risks, and anticipate machine maintenance. Ultimately, it helps supply chain leaders plan operations in advance so that they can grow consistently.

Our platform uses AI and sensor-based computer vision technology. It can help you identify defects instantly, reduce rework, and maintain consistent product quality. It requires little to no manual intervention and catches 99% defects in real time.

Our platform connects IoT sensors across equipment, vehicles, and storage environments to capture live operational data. With its real-time insights, you can monitor performance, environment, and movement in real time to improve control and asset efficiency.

Our platform runs on a secure, scalable cloud framework. And it allows supply chain organizations to connect systems, partners, and teams across locations to connect, synchronize data, and access it anytime, from anywhere.

Our platform continuously analyzes operational data and adjusts workflows in real time. Our AI experts provide maintenance and support to ensure that your supply chain is adaptive, efficient, and agile.

Our AI agents are designed to solve real supply chain challenges quickly, reliably, and at scale.

Automate with confidenceAutomates purchase decisions, manages sourcing, and ensures cost-efficient procurement

Handles supplier onboarding, compliance tracking, and performance monitoring

Balances stock levels across locations and reduces carrying and shortage costs

Predicts demand changes using data patterns to improve planning accuracy

Plans production runs dynamically to match capacity with real-time demand

Detects equipment issues early and schedules maintenance before breakdowns

Identifies product defects instantly using visual and sensor-based inspection data

Chooses best routes and carriers to cut transport time and costs

Tracks and validates orders in real time for faster and error-free delivery

Resolves customer queries instantly with live order and delivery data access

Monitors disruptions, market changes, and compliance risks to prevent delays

Collects sustainability data automatically and generates compliance-ready reports.

Supply chain automation is the use of technology to perform routine and data-driven tasks automatically. It improves accuracy, reduces delays, and helps businesses respond faster in complex and changing markets.

The main types of supply chain automation are process automation, Robotic Process Automation (RPA), warehouse automation, and AI-based decision automation. Each enhances efficiency and ensures smooth coordination across operations.

AI and predictive analytics improve demand forecasting by analyzing patterns in real-time and historical data. They predict future demand accurately and help balance production, inventory, and supply.

Automation creates a responsive and resilient supply chain by detecting disruptions early and adjusting operations instantly. It ensures business continuity and faster recovery from unexpected challenges.

AI enhances visibility through real-time data insights, boosts velocity by automating decision-making and optimizing workflows, and manages variability by predicting demand shifts, disruptions, and maintenance needs.

Automation improves ATP and CTP by updating inventory, production, and logistics data in real time. It enables accurate delivery commitments and better production planning.

Vendor-managed inventory with AI provides suppliers real-time visibility into stock and sales data. It automates replenishment, reduces shortages, and strengthens supplier relationships.

Navigate your great supply chain reset with AI

We help you achieve meaningful automation with the right data, connected systems, and redesigned processes.