Ask yourself: What if your supply chain could think, analyze, and predict – rather than react after a disruption hits?

For decades, businesses have relied on traditional supply chain processes, which are fragmented and struggle with inefficiency, rising costs, and unpredictable market shifts. The old process is no longer profitable. Logistic bottlenecks, demand fluctuation, and labor shortages expose the crack in the old system.

Freight transportation, including warehousing and ports, accounts for up to 11% of global greenhouse gas emissions and emits over 20% of the world’s black carbon.

–Network on European communications and transport activities research (NECTAR)

An urgent global challenge is posed by CO2 emissions. Are you curious to know how this environmental emergency can be resolved? If yes, then this blog post is for you. Stay tuned to learn how digitalization in the supply chain has become a game changer.

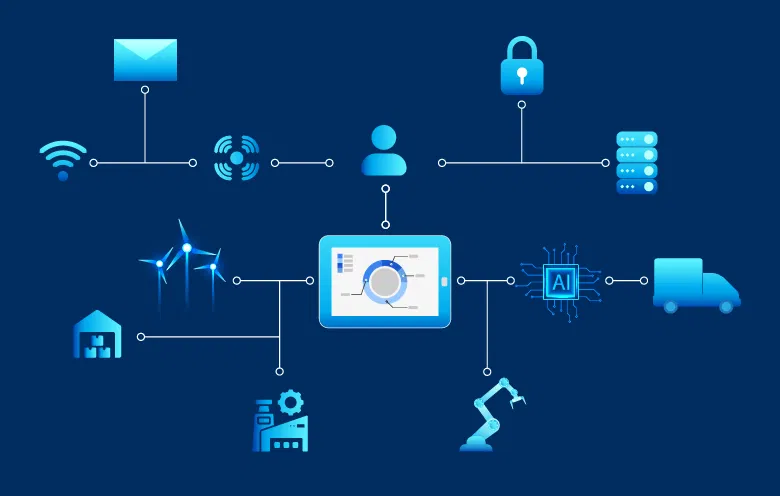

The modern era comes with a digital solution to the fragmented supply chain process. Revolutionizing business with the power of digital supply chain transformation has gained traction among business leaders. Digital supply chain in 2026 is rewriting the rules facilitating:

- AI-driven insights

- IoT enabled tracking

- Blockchain transparency

Thanks to digital transformation, supply chain management is becoming smarter. Can you guess what the results will be?

- Faster decision-making

- Reduced risks

- Competitive edge

According to the latest survey co-conducted by the Council of Supply Chain Management Professionals, 93% of companies say they are actively engaged in digitalizing their supply chains.

How is digital transformation reshaping supply chain?

Digital transformation in supply chain is the process of embedding innovation throughout the entire supply chain framework based on a strategic vision to empower collaboration within the department. It helps break down silos, improve efficiency and decision-making processes.

Digital transformation helps businesses collect, analyze and share supply chain information at any stage from:

Outdated vs. Automated: The supply chain transformation

Businesses are now leveraging modern technologies to create fully connected and automated operations. The old systems are now replaced by cloud-based solutions. Let’s examine how supply chain management has progressed from outdated methods to cutting-edge automation.

| Aspect | Outdated | Digital (automated) Supply Chain |

| Technology | Manual processes and spreadsheets | AI, IoT, Blockchain |

| Visibility | Limited and manual tracking | Real-time, AI-powered analytics |

| Decision making | Slow response and reactive | Data-driven insights and predictive analysis |

| Cost | High operational cost | Optimize cost through automation |

| Inventory control | Overstocking and stockouts | Demand forecast with AI |

| Risk | Vulnerable to disruptions | Proactive risk management |

Insights:

For a successful supply chain transformation, leaders must advocate new technology and set clear goals to drive automation and efficiency.

Major trends shaping digital supply chains in 2026

1. AI-driven predictive analytics

- AI and machine learning help forecast demand, streamline inventory management, and prevent disruptions.

- Real-time data helps with proactive decision-making rather than reactive decision-making.

Challenges: Traditional supply chains struggle with rapid demand fluctuation leading to stock shortages or excess inventory.

Solutions: AI-driven predictive models analyze market trends, past sales, and external factors like holidays and weather to streamline inventory levels and procurements in real-time.

Use case: Amazon uses AI-powered demand forecasting to reduce stockouts and optimize inventory levels.

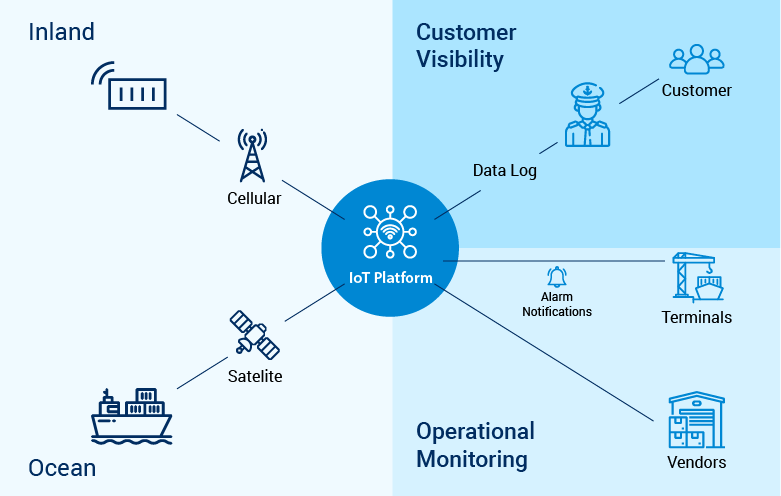

2. IoT and real-time visibility

- Offers improved monitoring of temperature-sensitive shipments for industries like food and pharma industries.

- IoT devices and smart sensors provide real-time tracking for goods in transport.

Challenges: Lack of live tracking leads to perishable waste, lost shipments, and insufficiencies in logistics.

Solutions: IoT-powered tracking devices continuously monitor shipments, ensuring reduced losses, better decision-making, and enhanced customer satisfaction.

Use case: Maersk has equipped its shipping containers with IoT sensors to monitor real-time temperature, humidity, and location, ensuring enhanced visibility and control over shipments.

The below image shows how AI technology and IoT sensors helps businesses to track shipping containers.

3. Cloud-based supply chain platform

- Enhance collaboration, scalability, and real-time communication.

- Fosters seamless data sharing between distributors, producers, and manufacturers.

Challenges: Fragmented data between supply chain partners often results in miscommunication, delays, and lost efficiencies.

Solutions: Cloud-based platforms offer seamless, real-time data sharing, enhancing collaboration, shortening turnaround time, and improving operational agility.

Use case: Unilever integrates cloud technology into its supply chain to unify operations across distributors, suppliers, and retailers globally. That will reduce the environmental impact of its products by 50% by 2030.

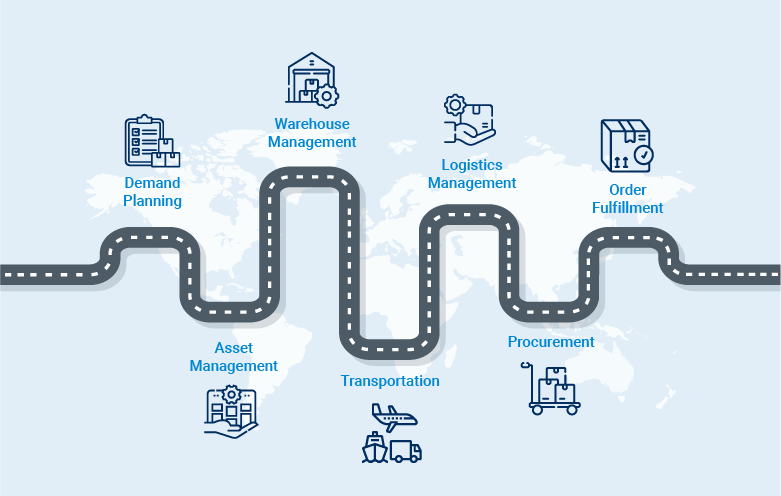

Smart logistics: Leveraging AI for superior supply chain management

Digital revolution in supply chain management has streamlined the way businesses handle stocking, inventory, warehousing, reducing carbon emissions and enhancing efficiency.

4. Sustainable and green supply chain practices

- AI-driven resource management helps cut waste and improve efficiency.

- Digital tools optimize routes and reduce carbon footprints.

Challenges: High levels of carbon emissions, waste, and operational inefficiencies are driving supply chains toward unsustainability.

Solutions: By leveraging AI in logistics, optimizing routes, and embracing clean energy, businesses can cut waste, reduce carbon emissions, and drive sustainability.

Use case: Tesla has integrated AI in its logistics and production processes to lower emissions and boost efficiency.

Insights:

According to the network on European communications and transport activities research (NECTAR) the supply chain generates 60% of the global carbon emission.

5. Supply chain automation & robotics

- Automation in warehousing, logistics, and packaging enhances speed and efficiency.

- Use of robotics for tasks like order picking and sorting does.

Challenges: Manual warehouse operations slow down order fulfillment, and increase errors, and labor costs.

Solutions: Warehousing operations are effectively managed by robotics and automated systems reducing human errors, accelerating order processing, and improving overall productivity.

Use case: Walmart has adopted AI-powered automation for its warehousing operations that has improved sorting, packing, inventory handling, and restocking.

4 Strategies for seamless digital supply chain transformation

Designing a robust supply chain strategy is vital for every organization that is preparing for digital transformation. The strategy should consist of four components that combine to facilitate a well-rounded and efficient transformation.

1. Examining current capability

Carefully evaluate your existing workforce competency, supply chain operations and technologies to pinpoint gaps, and willingness for digital upgrades.

2. Setting clear objective

Set specific and clear goals for digital transformation in a supply chain that is congruent with business priorities.

3. Focusing on key initiatives

Prioritize high-impact areas of your supply chain and design a road map to manage and win short-term goals with long-term strategic initiatives.

4. Encouraging digital culture

Foster a mindset that embraces innovation and digital adoption throughout your organization.

Benefits of digital supply chain transformation

Digital supply chain transformation improves visibility, speed, and control across sourcing, production, and delivery. It removes manual delays, reduces risk exposure, and creates predictable, data-driven operations.

-

Cost savings

Digital supply chains enable organizations to reduce costs by maintaining optimal stock levels, minimizing transportation expenses through route optimization and load consolidation. Using predictive maintenance, businesses reduce equipment downtime and extend asset lifespan, thereby enhancing their return on investment.

-

Improve operational efficiency

Automating routine tasks and streamlining complex processes using digital technology reduces manual error and enhances operational efficiency. For instance, automated procurement triggers purchase orders when inventory levels are low, thereby speeding up order fulfillment without requiring additional investment.

-

Enhanced visibility

Real-time visibility into inventory, shipments, and operational workflows allows businesses to identify issues immediately and maintain accurate inventory levels across multiple locations. When everyone has access to the same and accurate information, collaboration improves, and decision-making becomes quicker.

-

Increased agility and responsiveness

Organizations can easily modify their strategies and operations with digital supply chains when market conditions change, and unexpected disruptions occur. IoT sensors and routing algorithms can change shipment processes in real-time based on whether or delivery priority.

-

Enhanced customer experience

By implementing AI in the supply chain process, customers can track their orders and receive accurate delivery estimates. Businesses personalize services at scale by offering customized products and delivery options based on individual preferences, enhancing customer satisfaction.

-

Risk management and resilience

Digital tools enable businesses to identify, assess, and mitigate supply chain risks. Supplier risk monitoring systems continuously evaluate the financial health, compliance status, and performance of vendor networks, enhancing resilience during frequent disruptions.

Accelerate supply chain performance with digital intelligence

Managing a supply chain is complex, but timely action in the right direction drives stronger performance. Digital supply chain solutions use IoT sensors, GPS tracking, and RFID tags to deliver real-time visibility across products, assets, and vehicles. Beyond tracking, advanced analytics identify potential disruptions early and enable businesses to run operations smoothly.

According to Gartner, business leaders will se 100% shift to intelligent automation for processes like logistics, distribution and production. AI enables businesses to streamline complex processes, automate repetitive tasks, and enhance productivity. Talk to our experts to modernize your supply chain operations, improve visibility, and drive measurable performance gains through smart digital solutions.