AI-powered predictive maintenance utilizes artificial intelligence in assessing equipment condition, anomaly detection and predictive failure before occurrence. It works based on historical and real-time data to predict unexpected breakdowns and helps companies to apply proactive measures ahead of time. Machine learning enables predictive maintenance by identifying patterns in data and provides warning signals in the early stage, increasing predictive accuracy over time. This approach helps businesses to reduce unexpected interruptions, extend asset life, and maximize maintenance work to make operations more efficient.

This blog explores what is AI in predictive maintenance, its importance, the difference between preventive and predictive maintenance, the technologies used, how machine learning works in predictive maintenance, and real-world examples.

What is AI in predictive maintenance?

AI in Predictive maintenance is an approach that employs a data-driven methodology to identify and foretell early warning symptoms of machine breakdown through artificial intelligence, machine learning, and the Internet of Things.

As opposed to conventional methods where they rely on a set schedule and respond after the breakdown, predictive maintenance collects data from history, engine, transmission, battery, and brakes. Such a data-driven approach assesses the running condition and initiates the requirement for maintenance in a timely manner.

Why is predictive maintenance important for your business?

AI in predictive maintenance identifies machine failure in real-time, enabling businesses to eliminate expensive machine failure. This strategy enhances asset life span, optimizes maintenance schedule, boost productivity, and minimizes downtime.

By observing patterns in data, organizations can make informed decisions about when equipment should be used and when it should be replaced. This ensures operations are continuous without interruption, preventing downtime in the production and supply chain processes, and enhancing customer satisfaction.

McKinsey estimates that AI-driven predictive maintenance could reduce maintenance costs by 10-40% and cut downtime by up to 50%.

Benefits of AI in predictive maintenance

AI in predictive maintenance allows companies to shift from reactive to proactive approaches. These are the main advantages that make operations smoother, more reliable, and more intelligent planning.

- Reduces costs: Precise predictions of equipment failure can enhance maintenance planning, reduce surprise downtime, and the expense related to it.

- Forestall downtime: AI avoids equipment breakdown by forecasting potential problems with accuracy, allowing manufacturers to be one step ahead of mechanical problems, and making them more in uptime.

- Increase production: AI for predictive maintenance helps companies increase productivity by 5%–20% and reduce downtime by 15% shared by Deloitte.

- Improves safety: AI model-produced real-time data triggers signals that allow decision-makers to act quickly, ensuring the safety of employees.

- Extends equipment lifecycle: By avoiding premature wear and tear, AI-powered data analytics software can extend a mechanical asset’s lifespan, improving manufacturer uptime and revenue.

Preventive vs predictive maintenance approach

Preventive and predictive maintenance go about equipment maintenance in different ways. One reacts to conditions in real-time, while the other is proactively scheduled.

Understanding the difference assists you in selecting the correct strategy for long-term performance and minimal disruptions.

| Category | Preventive maintenance | Predictive maintenance |

|---|---|---|

| Data dependency | Relies on historical averages and manufacturer recommendations. | Uses real-time data from sensors and systems for maintenance decisions. |

| Scheduling | Maintenance is scheduled based on time or usage intervals | Maintenance is scheduled based on real-time data and equipment condition |

| Resource utilization | Manual labor and equipment parts are used unnecessarily, even if there’s no actual need. | Allocates resources more effectively by acting only when indicators suggest a need. |

| Downtime management | Downtime is scheduled but may still occur unexpectedly if failures happen between checks | Downtime is planned more accurately, minimizing disruptions |

| Cost efficiency | Can lead to unnecessary part replacements and higher maintenance costs over time | Helps reduce costs by avoiding over-maintenance and preventing unexpected failures. |

| Failure risk | Reduces risk to an extent but cannot catch unexpected issues outside the schedule. | Detects early signs of wear or malfunction, lowering the risk of sudden equipment failure. |

How is AI used in predictive maintenance?

AI predictive maintenance enables industries like manufacturing, package delivery, mining, fleet operations, and energy by detecting problems and trends beforehand. Through the use of machine learning in predictive analysis, companies now plan maintenance, track equipment health, forecast failure, identify anomalies and outages, and suggest remedial steps. Here’s how AI assists:

1. Failure prediction

Predictive maintenance based on AI relies on data from real-time sensors and past performance to predict equipment failure, keeping companies from unplanned disruptions. This approach learns, adapts, and predicts using huge amounts of data to improve accuracy.

Deep learning and defect detection, predictive maintenance machine learning model, does away with the use of human observation. These assist companies in saving time by identifying failure beforehand, improving the quality of product and customer experience.

2. Energy optimization

Old machines lose efficiency as time passes; they use increased amounts of energy to deliver the same output. Applying AI to predictive maintenance, machine owners and manufacturers can discover defects in the machines, schedule repairs well in advance, and avoid scrap and rework. AI algorithms also maximize energy across the manufacturing facility using digital twins and machine learning to determine waste and suggest methods to eradicate it.

3. Prioritizing maintenance

AI optimizes maintenance planning by monitoring issues, identifying priorities, and re-prioritizing maintenance in real time. Rather than designing schedules on historical data or concentrating on existing problems, AI predictive maintenance examines the health of the equipment and foretells the result. This is a step ahead that corporations can take to increase efficiency in their operations.

4. Defect detection

Companies are able to train an AI to observe and review flaws from the videos captured via computer vision, which scans machine conditions in real time. Visual images serve as supplementary information that complements other data by detecting elusive flaws like wear and tear, misalignment, and broken packaging. Detecting defects via images draws attention to the underlying cause of the issue so that measures can be taken for prevention.

AI technologies used for predictive maintenance

Modern predictive maintenance relies on a blend of AI-powered technologies to detect issues early, improve decision-making, and extend asset life. Below are key technologies driving this shift:

- Computer Vision (CV): Examines images or video streams to identify surface flaws, wear, or misalignments without human inspection.

- Machine Learning (ML): Machine learning model learns trends from historical and real-time data to forecast equipment breakdowns and suggest timely interventions.

- 3D models: Develops digital twinning of machinery to model operations, track performance, and simulate maintenance scenarios virtually.

- Big data: Processes and aggregates large amounts for in-depth understanding of equipment health and failure patterns.

- IoT sensors: Measures temperature, vibration, pressure, and other parameters to provide real-time tracking.

- Edge computing: Processes sensor data locally to give real-time feedback, even in remote or bandwidth-constrained environments.

- Cloud platforms: Aggregates data from many sources, allowing scalable analysis and predictive modeling across facilities.

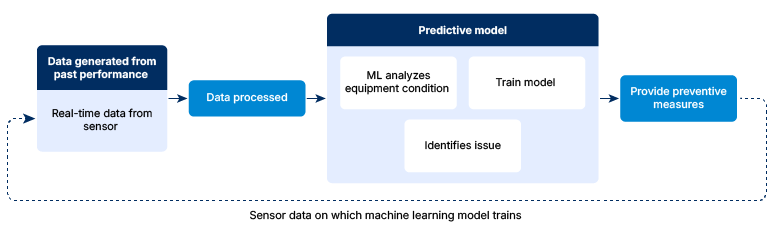

How does AI in predictive maintenance work?

AI-powered predictive maintenance works by continuously monitoring equipment conditions. It identifies early signs of failure, enabling proactive action, reducing downtime, and improving reliability.

1. Data collection

Sensors attached to equipment collect real-time data such as vibration, temperature, humidity, noise, and pressure. This data is then used to analyze the health condition of the equipment and its operational trends. Thus, extracting accurate data helps AI to analyze data for further processing.

2. Data analysis

The collected data is analyzed using machine learning and AI models to identify trends, patterns and anomalies that reveal a potential machine failure. ML models are trained to point out scenarios that can result in equipment failure. Thus, data analysis helps in forecasting issues before they can disrupt operations.

3. Predictive modeling

Based on the analysis, AI models predict the current condition of the equipment and estimated usage left before replacement or maintenance. AI models constantly train themselves with acquired data to make context-specific and accurate predictions.

4. Alert and recommendation

When issues are detected, the system generates an alert and suggests actionable steps like schedule maintenance. These suggestions help the team take timely action to avoid breakdown. Thus, proactive measures prioritize maintenance required to prevent downtime.

5. Continuous improvement

AI platforms are integrated with business assets or operating to generate real-time data. This process ensures predictions are accurate and maintenance task are seamlessly executed.

Real-world examples of AI in predictive maintenance

Real-life scenarios demonstrate the ways in which AI-based predictive maintenance aids industries in identifying problems early on, averting failures, and maintaining business operations in a smooth manner. Such scenarios emphasize real-world applications that enhance reliability, safety, and cost effectiveness across industries.

1. Siemens adopted AI to improve its manufacturing processes

Siemens, a manufacturing firm, uses AI-based predictive maintenance software for industrial machinery, to anticipate when equipment like turbines, compressors, or conveyors will break down. AI algorithms gather real-time sensor inputs like temperature, pressure, vibration, and revolution speed. These are then analyzed to determine anomalies and predict failures based on patterns learned from past data.

2. General Electric implemented AI to enhance its operations in energy sector

General Electric (GE) has used AI-driven predictive maintenance to track and analyze infrastructure like gas turbines, wind turbines, and power plants. The systems use sophisticated machine learning algorithms to identify likely failures based on sensor data read from turbines in real time.

3. Cisco implemented AI to enhance it networking and IT infrastructure

Cisco, a world leader in networking solutions, employs AI-based predictive maintenance tools for IT infrastructure management. Cisco Catalyst Center, an appliance network management system, has machine learning for predictive maintenance to monitor network traffic patterns, device behavior, and system health. With AI-based predictive maintenance, it can lower network downtime considerably, enhance service availability, and make critical systems more reliable.

4. Tesla integrated AI to improve its automobile operations

Tesla used AI to monitor vital car parts such as braking and battery condition, making performance real-time monitorable. Such an anticipatory process enabled the firm to catch issues in the early stage and take immediate action that enhanced vehicle performance as well as customer satisfaction.

5. Mercedes-Benz Trucks Uptime implemented AI to enhance operations for logistic companies

Mercedes-Benz Trucks Uptime uses AI to monitor truck components, providing advance alerts of potential equipment failure, and reducing downtime for logistics companies. Machine learning-based predictive maintenance automates fleet management through adequate servicing of vehicles when they are due and enhancing overall efficiency.

Streamline operations with predictive maintenance

Predictive maintenance with AI is no longer a differentiator; it has become a necessity for businesses that need to reduce downtime, eliminate expenses and expand the asset life. To successfully implement predictive maintenance businesses must invest money in the right technology and AI consulting service to build a culture of data-driven decision making and collaborate with AI experts who help you with integration and deployment. Success belongs to one who adopts AI to make their maintenance operations an active strength.

Ready to optimize your maintenance strategy with AI?

Connect with our experts to design a predictive maintenance solution tailored to your assets, goals, and operational priorities.

FAQ

1. How to implement machine learning predictive maintenance?

There is a systematic approach to applying machine learning for predictive maintenance. Data is collected from sensors and past maintenance history. These data are pre-processed and cleaned to make it ready for further analysis. Then machine learning models are trained to identify patterns and forecast failure. The model is then connected with a real-time data monitoring system to predict maintenance tasks. These models constantly train on the data received to improve accuracy over time.

2. Which industries benefit most from implementing AI-driven predictive maintenance?

Industries that have high asset value like automotive, manufacturing, energy, logistics, telecommunication and aerospace get the most benefit from AI in predictive maintenance. With industries that completely rely on operating equipment, AI becomes crucial in ensuring that unplanned downtime is reduced as maintenance schedule is optimized using predictive analytics, enhancing asset life.

3. How can AI extend the lifespan of industrial assets through proactive care?

AI prolongs asset life in industries by constantly tracking equipment health, identifying onset of wear, and anticipating likely failures. This allows for interventions in advance, minimizes component stresses, and avoids expensive breakdowns to maintain the machinery in operational condition longer with less downtime and optimal maintenance schedules.

4. What cost savings can organizations expect from AI-based predictive maintenance?

AI-powered predictive maintenance can save unplanned downtime by as much as 30% and increase asset lifespan by 20–40%, resulting in substantial savings. Organizations also reduce costs in maintenance by 10–20% through early intervention and less labor. This translates to saving millions, particularly in industries with assets.

5. How is AI used for predictive maintenance in energy facilities?

AI in energy plants utilizes sensor signals from turbines, transformers, and other machinery to identify anomalies and predict failures. Analyzing temperature, vibration, and performance pattern trends, AI makes maintenance possible ahead of time, decreases unplanned outages, and increases asset life. This enhances reliability and reduces operating costs throughout power generation equipment.

6. How does AI enhance predictive maintenance in manufacturing?

AI improves predictive maintenance in manufacturing by processing sensor data to identify early warning signs of equipment failure. It detects patterns and anomalies and allows for timely interventions that decrease downtime, prolong machine life, and enhance safety. This helps manufacturers plan maintenance schedules more efficiently and ensure consistent production efficiency.

7. What are the top benefits of AI-powered maintenance forecasting?

AI-powered maintenance forecasting reduces unexpected equipment failures by predicting issues before they happen. It helps schedule maintenance at the right time, extends asset lifespan, and cuts operational costs through data-driven decisions.

8. Which industry benefits from AI agents for predictive maintenance?

Industries such as manufacturing, energy, utilities, transportation, and oil & gas benefit the most from AI agents for predictive maintenance. These sectors depend on high-value assets that must operate continuously and efficiently, making early fault detection essential.

9. What are the top benefits of AI in maintenance planning?

AI improves maintenance planning by analyzing real-time data to determine the best time for repairs. It reduces manual guesswork, optimizes resource use, and increases equipment reliability through accurate scheduling.

10. How to use AI to predict maintenance needs from usage data?

AI processes equipment usage data, sensor readings, and performance logs to identify patterns that signal wear or failure. By interpreting these patterns, it predicts when maintenance is needed, helping businesses act before problems occur.

12. How predictive maintenance and application of AI prevents unplanned downtime?

Predictive maintenance uses AI to monitor equipment health and detect potential issues early. It enables proactive maintenance scheduling, preventing sudden failures and reducing unplanned downtime across critical operations.