Quality inspection in manufacturing

Detect and resolve defects in real time to minimize loss, maintain uptime, and achieve uncompromised production quality.

Schedule a callOur Clients

Your production line’s quality directly impacts your bottom line and market position. When quality deviations such as surface blemishes, damaged labels, or critical component failures go undetected, you face costly recalls, production downtime, and long-term damage to customer relationships.

Softweb Solutions can help you catch defects at production speed so that you can achieve zero-defect output and protect your brand reputation. Our experts develop AI-powered inspection solutions tailored to your manufacturing operations and quality requirements. We integrate our quality inspection solutions into your existing systems that withstand harsh industrial environments such as extreme temperatures and corrosive chemicals, eliminate bottlenecks, and reduce waste by up to 40%. We integrate machine vision AI to ensure every product meets specifications across food, pharmaceuticals, electronics, automotive, and semiconductor industries.

Our automated defect detection system captures scratches, misalignments, or deformities across materials and assemblies. We help you maintain consistent product standards while reducing inspection costs and human error throughout your production cycle.

We deliver accurate real-time product counts for components and kits by tracking them from production through dispatch. Our high-speed machine vision counts microscopic objects in real time and updates your ERP automatically. This eliminates manual counting errors, improves accuracy, and production efficiency across your assembly and dispatch operations.

We deploy intelligent label inspection systems that instantly detect, read, and verify product labels against regulatory requirements and specifications. Using computer vision technology, we verify barcode data, print alignment, and packaging integrity in milliseconds. This reduces label errors, misalignments, incorrect information, and barcode issues before products ship.

Our predictive maintenance solution continuously monitors equipment performance by analyzing real-time video and sensor data, reducing unexpected downtime. By forecasting maintenance needs, we help manufacturers extend machine lifespan, improve operational reliability, and achieve significant cost savings on unexpected repairs.

Our automated quality inspection system accurately identifies, counts, and tracks specific products throughout assembly and shipment stages. It seamlessly integrates data with ERP systems to verify purchase orders. This ensures correct products are shipped to customers, eliminating recall costs.

We deploy AI for defect detection in manufacturing that identifies foreign objects including metal fragments, plastic pieces, and unintended materials in production lines with exceptional precision. Our system combines advanced imaging and real-time analytics to ensure safety standards and prevent costly recalls.

Achieve zero-defect manufacturing with intelligent quality inspection.

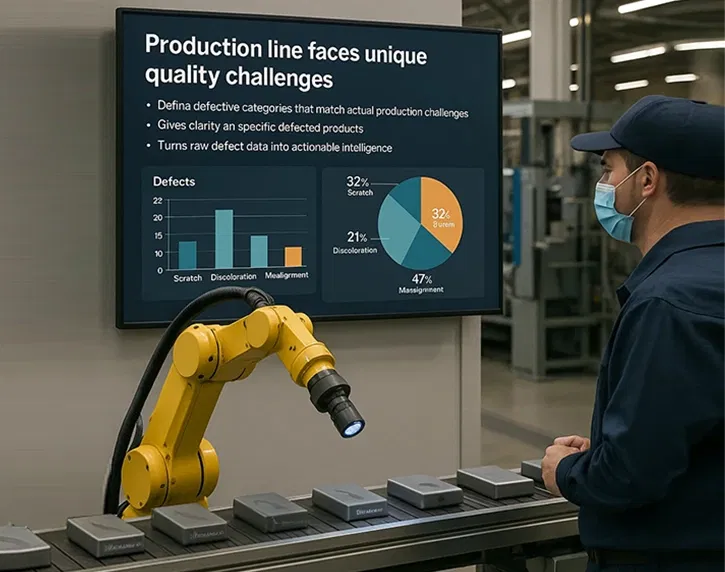

Schedule a callWe understand that every production line faces unique quality challenges. Our system lets you define defective categories that match your actual production challenges. This capability is useful when you need unique labels beyond set standards. It gives clarity over component-specific failures, production shifts, or vendor responsibility. This customization turns raw defect data into actionable intelligence and addresses your specific quality challenges.

Our AI-based visual inspection system uses convolutional neural networks to analyze product images with human-like perception and machine-like consistency. This approach enhances defect detection in manufacturing by adapting to new product variants and automatically identifying deviations. You can dive into specific defect patterns, compare performance across shifts, and spot emerging issues.

We provide instant visibility into quality metrics through intuitive dashboards that display defect rates, production trends, and anomaly patterns in real-time. When defects are identified, the system alerts your team and allows them to take action before they escalate. This reduces response time from hours to minutes and prevents defective products from shipping.

Our architecture minimizes bandwidth costs by processing inspections locally and sending relevant data, such as defect images, metadata, and summary statistics, to the cloud. This approach delivers faster rejection of defective parts, lower bandwidth costs, and a platform you can scale as your inspection needs evolve.

We embed our end-to-end defect detection solution in your production environment through seamless integration with MES, ERP, and SCADA. This enables inspection data to trigger predefined processes, alert the procurement team, and update KPIs. You can transform isolated quality data into enterprise-wide intelligence with this integration.

Cost savings

Minimize material waste with early detection that prevents entire batches from becoming unusable

Speed and consistency

Accelerate time-to-market by identifying and resolving quality issues earlier in production runs

Predictive quality inspectionq

Anticipate equipment degradation that affects quality, enabling maintenance before failures occur

Real-time inspection and feedback

Receive instant alerts when quality parameters deviate, enabling immediate corrective action

Workforce enablement

Release skilled workers from repetitive inspection tasks to focus on problem-solving and improvement

Scalability

Grow inspection capacity as your business expands, maintaining speed and consistency everywhere

Defect detection at production scale with precision-engineered inspection systems.

Talk to our expertsAI-powered inspection systems continuously evolve to enhance and refine quality benchmarks. As they process new images and defect patterns, these models automatically train themselves for higher accuracy. This autonomous improvement reduces human intervention while enhancing accuracy and reliability.

The convergence of edge computing, 5G networks, and cloud platforms enhances inspection capability by balancing real-time local processing with centralized analytics and management. Manufacturers will receive instant feedback, optimized bandwidth consumption, and uninterrupted analytics even in remote or high-load environments.

Integrating predictive maintenance with quality inspection creates closed-loop feedback systems. Advanced analytics identify relationships between machine performance and product quality that human observations would never detect. This enables predictive models to forecast quality degradation before it escalates.

A scalable inspection system uses edge computing for real-time inspection decisions and cloud resources for computationally intensive tasks, such as model training and cross-facility analytics. It supports the flexible and adaptive manufacturing operations central to Industry 4.0, where production capacity and product mix change rapidly in response to market demands.

Our defect detection solutions are specifically designed to meet the requirements of different industries.

10+ years of experience transforming quality inspection across industries

60+ member team skilled in defect detection, image analysis, and process optimization

Ready-to-use inspection frameworks that reduces deployment time by up to 35%

Seamlessly connects with on-premises and cloud environments for real-time insights

Trusted by manufacturers to reduce scrap, rework, and downtime through automated inspection

Computer vision–based quality inspection is a technology-driven process that uses industrial cameras and image processing systems to automatically detect product defects on the production line. It captures and analyzes visual data such as shape, texture, color, or surface finish to ensure that every product meets defined quality standards.

Computer vision eliminates human subjectivity by using high-resolution imaging and precise algorithms to spot even the smallest deviations. It maintains uniform inspection standards across all shifts and production lines. As a result, manufacturers achieve higher accuracy, fewer false rejections, and greater consistency in product quality.

By continuously monitoring equipment and product output, computer vision identifies potential quality issues before they lead to machine stoppages. Early detection allows operators to address faults immediately without halting production. This proactive approach minimizes unplanned downtime and keeps production running smoothly.

Yes, modern inspection systems are designed to integrate easily with existing machinery, PLCs, and control systems. They can be connected through standard industrial interfaces to collect data and trigger real-time actions. This compatibility ensures smooth adoption without major changes to current workflows or infrastructure.

Computer vision helps reduce material waste by detecting defects early and preventing defective products from moving further down the line. It enables manufacturers to optimize resource use and maintain higher production efficiency. This not only lowers operational costs but also supports long-term environmental goals.

Every inspection generates data on product performance, defect types, and process variations. Over time, this data is analyzed to refine inspection criteria, update defect libraries, and improve detection accuracy. Continuous learning from production data helps the system adapt to new product designs and maintain reliable performance.

Detect defects before they escalate with automated quality inspection

Connect with our specialists to design a smarter inspection workflow that ensures zero-defect manufacturing.