Client profile

Our client is a global semiconductor manufacturer with a broad portfolio of analog, power, and mixed-signal devices. The company serves design engineers, procurement departments, and distributors who rely on accurate technical data, lifecycle information, and clear guidance on compatible parts. Over the past two decades, it has grown through multiple acquisitions, expanding its presence across industrial, automotive, and communications markets. It sells through a combination of direct channels and a large international distributor network.

Technical challenges

The client’s product information landscape reflected its accretive growth. Each acquired business brought its own tools, attribute models, and catalog processes. Their online catalog covered more than 45,000 product SKUs defined across nearly 100 templates, each with its own information extraction script. Over time, this created a complex environment of legacy systems and partial PIM implementations that were never designed to support a modern, unified online product catalog.

Key technical challenges included:

- Multiple, overlapping product data stores

Product information was distributed across legacy PIM tools, local databases, ERP and PLM systems, and document repositories. Each system described devices with different field names, formats, and attribute sets. As a result, the same product had multiple records across systems, which created ongoing confusion about which data was current.

- Inconsistent attributes and descriptions

Core parameters such as voltage, current ratings, package type, or temperature range were represented differently by each business unit. Because attributes were not aligned, it became difficult to compare parts or present a clear, unified catalog experience to customers.

- Document-driven product updates

Many teams maintained PDFs and spreadsheets as the primary source of product truth. Developers then wrote and maintained scripts to extract data from these documents and upload it into the online catalog, making catalog updates slower and more likely to have errors.

- Developer-dependent web content

Marketing teams created content-rich pages in HTML and passed them to developers for upload. Around 200 such pages had to be handled this way, which made content updates slow and dependent on development capacity.

- Legacy ERP and PLM platforms

Some core systems were first deployed in the early 2000s and were not designed to integrate with web-facing applications. They lacked modern APIs and required custom export and load mechanisms, which complicated any attempt to centralize data.

- Limited ecommerce and search experience

Engineers struggled to locate suitable parts using the existing catalog interface. Parametric filters were incomplete or inconsistent, and lifecycle or compliance information was not always current, which discouraged self-service behavior.

- Knowledge concentrated in expert teams

Critical insights about alternatives, compatible products, and migration paths from obsolete devices were held by a small group of senior engineers and product managers instead of being captured in structured product data. When these experts changed roles or retired, teams struggled to answer basic questions on alternates and migrations, slowing down issue resolution.

Our solution

We designed and implemented a consolidated product information management solution for the client. The goal was to create one reliable product record that supports their online catalog, distributor channels, and analytics without disrupting core transactional systems.

Based on joint workshops with the stakeholders, we focused our work on these areas:

- Defining a standard semiconductor product model

We worked with engineering, product marketing, and business intelligence teams to understand how different semiconductor product lines vary in their technical complexity and usage. From these inputs, we created a standard attribute model for the entire portfolio. The model covered electrical and thermal parameters, package details, compliance and reliability data, lifecycle status, and recommended alternatives. It became the reference structure for all future product onboarding and normalization.

- Consolidating product data into a central PIM

Existing PIM instances, local catalogs, and spreadsheet-based lists were mapped into the new model. We implemented validation rules to align units, naming conventions, and value ranges, and used controlled lists to remove duplicate or conflicting attributes. The consolidation eliminated specification conflicts where the same product appeared with different definitions across systems. Teams now accessed a single, authoritative product record.

- Connecting PIM to ecommerce and distributor channels

The PIM became the source of product, pricing, and lifecycle data for the global online catalog and regional sites. It also provided structured feeds to key distributors, aligning part descriptions and attributes so that partners present consistent information to their own customers.

- Integrating legacy ERP and PLM systems

For older ERP and PLM systems, we defined stable extraction patterns using scheduled exports and ETL processes. Data was staged, validated, and transformed before loading into the PIM. Our ETL strategy kept legacy systems operational without requiring expensive system replacements. Product information flowed reliably from these older platforms to the new product hub.

- Enriching data with relationships and alternates

We extended the product model to capture cross-family relationships, recommended replacements for obsolete parts, and commonly paired devices. All the information about alternatives and relationships is now stored and maintained centrally. The engineers can now move from one candidate device to another without leaving the catalog.

- Enabling analytics and customer data platforms

We connected the PIM to the client’s analytics environment and customer data platform, creating unified visibility across product data, web activity, and sales outcomes. Business intelligence teams now analyze which device families and parameter ranges drive revenue. Sales strategy teams identify catalog gaps that represent missed opportunities.

-

Industry

-

Technologies / Platforms / Frameworks

PIM, ERP, PLM, ETL tools, CDP, Cloud analytics

-

Benefits

- Single source of truth: One central product record provides tools, web catalogs, and distributors with consistent data.

- Faster part discovery: Standardized attributes help engineers filter, compare, and choose from SKUs quickly.

- Faster, more reliable updates: Product teams update data in PIM, reducing manual scripts, document changes, and catalog errors.

- Consistent product data for new acquisitions: New product lines map into the shared model, preventing new product data silos.

Decades of Trust & Experience

1630+

Projects

545+

Experts

26+

Products and Solutions

1020+

Customers

Similar Case Studies

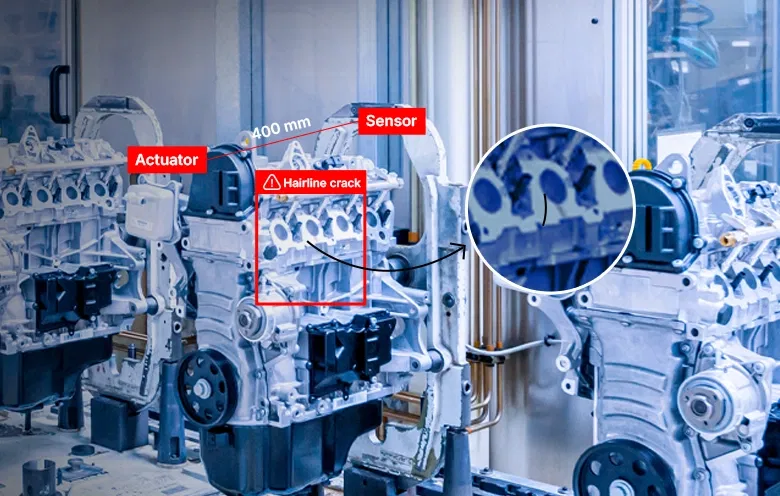

Enhanced quality control system for a manufacturing company with machine learning

Automatic defect detection on semiconductor wafer surfaces using deep learning

Solved inspection challenges for a semiconductor manufacturer

Connect Now

Our experts would be eager to hear you.