AI-powered defect detection for packaging

Stop defective packages from shipping with YOLO-based real-time packaging defect detection systems that inspect every unit at production speed

Talk to our AI expertOur Clients

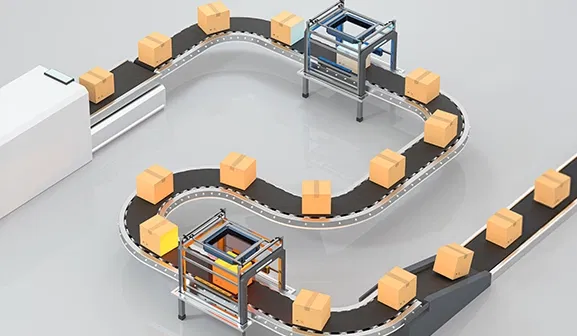

Your packaging represents your brand promise at every customer touchpoint. When defects like misaligned labels, seal failures, or printing errors reach customers, you face returns, complaints, and potential recalls that damage relationships and profitability. A real-time defect detection system can help you analyze every package during production and identify issues before they leave your facility so you can ensure only properly packaged products reach customers, maintain quality standards, and protect your brand reputation.

Softweb Solutions develops AI-powered inspection systems tailored to your production environment and defect patterns. Our 120+ AI specialists combine computer vision expertise with manufacturing domain knowledge across industries to build systems that integrate with your existing ERP, MES, and PLC infrastructure, learn your quality standards, and deliver actionable defect alerts without disrupting throughput.

We develop YOLO-based defect detection models trained on your packaging specifications, production conditions, and defect history to recognize issues specific to your operation.

Our systems connect directly with ERP, MES, and PLC systems to synchronize inspection data with production workflows, quality records, and automated sorting mechanisms.

We inspect packages at your production speeds without creating bottlenecks, maintaining accuracy as lighting and product positioning vary.

Our engineers collaborate with your quality and operations teams throughout deployment and model refinement. We support expansion to additional lines or facilities as your requirements evolve.

Our systems catch label placement and quality issues that affect compliance and brand presentation. These include:

We identify packaging integrity issues that compromise product protection and distribution efficiency. The system detects:

Our inspection system catches print quality problems that impact traceability and regulatory compliance. This includes:

We detect foreign materials and contaminants that compromise product safety before distribution. The system identifies:

Our systems identify seal integrity issues that could lead to product exposure or spoilage. The system catches:

We confirm that packages contain the correct product quantities and meet fill specifications. This includes detecting:

Real-time inspection

We detect defects instantly as packages move through your production line, analyzing visual data in real time to identify quality issues before products advance to downstream processes.

AI accuracy

Our machine learning models continuously improve detection precision as they process more production data, automatically refining defect recognition patterns and reducing false alerts over time.

Custom dashboards

Our solution visualize defect distributions, line performance data, and quality trends through dashboards that help your teams track inspection effectiveness and spot patterns requiring attention.

Automated alerts

Our system sends immediate notifications to operators when defects occur, specifying issue type, location, and severity to enable quick response without constant monitoring of inspection stations.

Scalable System

The system scales across multiple production lines and adapts to different packaging types, letting you standardize inspection capabilities throughout your facility or network.

Integration capabilities

Our systems connect with your existing ERP, MES, and PLC infrastructure, synchronizing inspection data with workflows and quality systems without disrupting production operations.

Work with our experts to deploy inspection systems that prevent defects, ensure compliance, and protect your brand.

Get started nowCatching defects before shipment prevents customer returns, complaint escalation, and the costs of processing rejected products that reach the market with quality failures.

Real-time inspection at line speed eliminates manual check bottlenecks, reduces downtime from quality investigations, and allows continuous production flow without throughput sacrifice.

Automated systems apply identical criteria to every package with consistent precision, delivering uniform quality across shifts, lines, and production facilities.

Lower inspection labor, reduced waste from late-stage defects, and prevented rework expenses directly improve operational margins.

Aggregated inspection data reveals defect patterns by shift, material batch, equipment condition, or production parameter, guiding targeted process improvements and preventive maintenance decisions.

Documentation of 100% inspection coverage with timestamped defect records and image evidence supports audit requirements and demonstrates systematic quality assurance for regulatory bodies.

Semiconductor packaging demands precision inspection to protect delicate components and maintain traceability throughout the supply chain. Our systems verify anti-static packaging integrity, moisture barrier seals, and identification labels that ensure chip safety while supporting strict documentation requirements for electronics manufacturing.

Electronics packaging protects sensitive components during shipping while communicating product specifications and brand identity. Our inspection systems verify protective packaging integrity, label accuracy, and regulatory compliance markings that ensure products arrive undamaged and meet certification requirements for consumer electronics markets.

Pharmaceutical packaging requires zero-defect standards and complete inspection traceability for regulatory compliance. Our inspection systems verify blister packs, vials, and labeled containers while documenting every quality check to support validation requirements and audit processes.

Brand reputation depends on consistent packaging quality across retail channels. Our defect detection systems inspect cosmetics, personal care products, household items, and packaged goods at line speed to ensure only properly packaged products reach store shelves and customer hands.

Distribution centers handle diverse product packaging that must withstand handling and transport without damage or label degradation. Our inspection systems verify package condition, shipping label accuracy, and handling instruction visibility before products enter distribution networks, reducing returns from packaging failures during transit.

High-volume packaging lines operate at speeds where consistent quality verification requires automated inspection. Our systems verify label accuracy, seal integrity, and container condition across beverage bottles, food containers, and packaged goods that demand both safety compliance and shelf appeal.

High-resolution cameras positioned at inspection stations capture your products as packages move through production at standard line speeds. Our system preprocesses these images by normalizing lighting, correcting perspective, and isolating packaging from background elements to create clean data ready for analysis.

Our computer vision algorithms examine captured images to identify edges, textures, patterns, and spatial features that distinguish normal packaging from defective characteristics. YOLO-based detection models then compare these extracted features against learned defect patterns, recognizing specific issues and assigning confidence scores to each detection.

When the system identifies defects exceeding your quality thresholds, it immediately sends notifications to operators, quality dashboards, and automated rejection systems based on your configured response protocols. This real-time alerting enables quick intervention without requiring constant monitoring of inspection stations.

Simultaneously with defect detection, our system generates detailed inspection records capturing product identifiers, defect classifications, image evidence, and decision reasoning. These reports flow into your quality management databases, creating complete traceability for compliance audits and enabling root cause investigations.

As inspection data accumulates from production runs, our systems analyze confirmed defects and false alert patterns to automatically refine detection thresholds and improve accuracy. This ongoing learning process improves defect recognition accuracy over time, adapting to packaging variations while maintaining sensitivity to genuine quality issues.

Defect detection in packaging is the automated process of identifying flaws such as label misalignment, seal failures, print errors, and structural damage that compromise product quality and safety. It uses computer vision and AI to analyze every package in real time, comparing visual characteristics against quality standards to flag issues before products leave production.

AI-powered inspection learns from production data to recognize subtle defect patterns and adapt to normal variation in your packaging. These systems distinguish genuine quality issues from acceptable differences, delivering higher accuracy and fewer false alerts than rule-based systems that rely on fixed thresholds and cannot adjust to changing production conditions.

Yes. Systems connect to existing ERP, MES, and PLC infrastructure through standard industrial protocols, allowing quality data to flow into your management systems without requiring line redesign or extended downtime.

YOLO models detect labeling errors, seal integrity issues, printing defects, foreign materials, structural damage, and dimensional inconsistencies by analyzing visual features specific to your packaging. The system learns from your defect examples and normal production variation to distinguish genuine quality issues from acceptable differences.

Systems analyze packages at your production line speeds, inspecting products as fast as they move through manufacturing without creating bottlenecks. Inspection keeps pace with line throughput from moderate-speed operations to high-volume production exceeding 1,000 units per minute, depending on package complexity and inspection requirements.

No. Once deployed, systems operate autonomously, sending alerts only when defects exceed thresholds or when operator intervention is needed for borderline cases or system performance verification.

Initial deployment requires representative images of acceptable packaging plus examples of each defect type. Systems then learn continuously from production, improving accuracy as they process more data.

Models trained on your product variations recognize acceptable differences in positioning, lighting, and material appearance while flagging genuine defects, reducing false alerts from normal production variance.

Yes. Systems store multiple inspection profiles and switch between products automatically based on line signals, supporting mixed-product lines without manual reconfiguration between runs.

Typical deployments reduce defect escapes by 90%+, lower inspection labor costs by 60-80%, and decrease waste from late-stage defect discovery, with payback periods of 8-18 months depending on line volume.

Ship only perfect packaging with AI-powered inspection that catches every defect

Build an inspection solution customized for your quality requirements, compliance needs, and production environment to eliminate defect escapes.