At Softweb Solutions, we transform manufacturing and other industries with advanced AI-powered computer vision services. Our visual inspection AI automates manual quality checks - improving accuracy, speeding up defect detection, and reducing costs. Using machine learning models to analyze images captured by cameras and sensors, we deliver real-time, high-precision inspection solutions.

Our expertise includes object detection, defect identification, classification, segmentation, and pattern recognition. We seamlessly integrate with existing systems like ERP, POS, CCTV, and cloud platforms-providing scalable, hardware-efficient solutions across manufacturing, healthcare, logistics, and more.

Softweb Solutions is your partner in boosting operational efficiency and product quality through cutting-edge visual inspection technology.

Ensure flawless products with AI-driven visual inspection and quality control. Our solution analyzes every item in real time, detects anomalies, and enforces consistency - delivering precision, speed, and reliability across your production line.

Softweb Solutions offers advanced image processing services like enhancement, segmentation, object detection, and classification. Our AI solutions provide real-time insights and integrate seamlessly with systems in healthcare, manufacturing, pharma and logistics etc.

Even the smallest defect can compromise quality and customer trust. We help you identify defects such as scratches, dents, discolorations, and alignment problems. Maintain brand integrity and deliver flawless products.

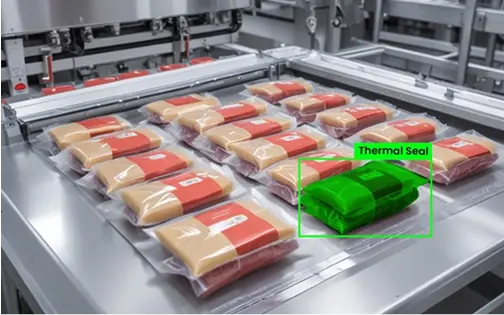

Our object detection service identifies multiple objects in images with clear labels and precise bounding boxes. Built for enterprise use, it supports custom models and handles large-scale data efficiently. Turn visuals into structured data for real-time decisions.

Your production environment is constantly evolving, and your AI models should evolve with it. We retrain your models using fresh data to help them recognize new defect types, sustain high accuracy, and deliver consistent, scalable results.

Capture and data curation from production for evolving defect patterns.

Retrain and validate your vision models using our automated pipelines.

Deploy updated models seamlessly to your existing infrastructure.

Explore vision AI solutions tailored for your industry - from manufacturing and healthcare to logistics, retail, and more.

Technocrats

Clients

Products and solutions

Projects

Softweb Solutions’ adaptive AI models enable real-time grading and sorting by recognizing subtle differences in size, shape, color, and surface defects-even at high speeds. From detecting damaged produce to ensuring only premium quality reaches the shelf, our vision AI ensures consistent, high-accuracy results with zero compromise.

Softweb Solutions uses custom vision AI algorithms to detect foreign objects such as debris, insects, plastic, glass, or metal during food production and packaging. Our tailored solutions help ensure product quality, protect consumer safety, prevent costly recalls, and support regulatory compliance.

Softweb Solutions transforms quality control through custom vision AI models. We automate inspections across industries to detect damage, mislabeling, and contamination. Real-time scanning minimizes bottlenecks and prevents costly recalls—ensuring a reliable supply chain that consistently delivers top-quality products.

Imagine eliminating inefficiencies like slow picking, order errors, and wasted space. Softweb Solutions' vision AI automates inspections and product recognition across the warehouse. Our advanced pallet and package recognition integrates with robotics to streamline sorting, picking, and packing. Cut costs and boost throughput with smart, efficient operations.

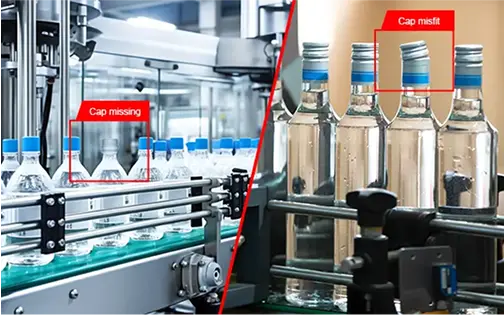

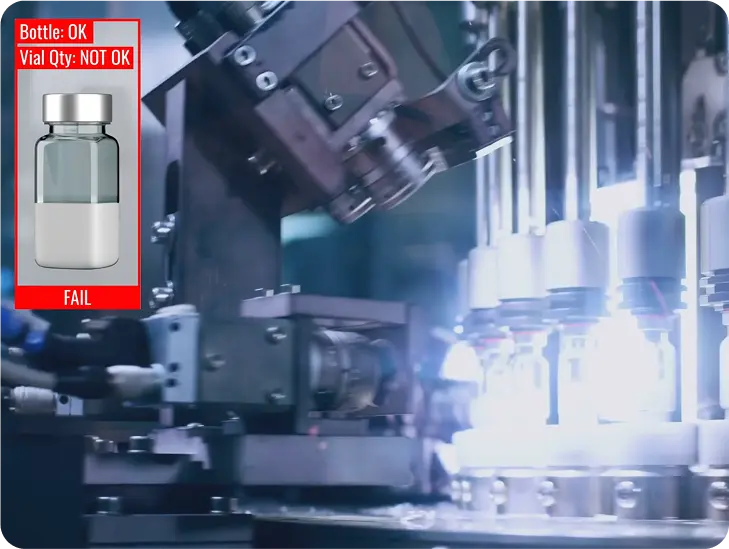

Softweb Solutions’ vision AI ensures every bottle is sealed perfectly by detecting missing, misaligned, or damaged caps in real time. With high-speed accuracy, it prevents leaks, contamination, and quality escapes ensuring product integrity from line to shelf.

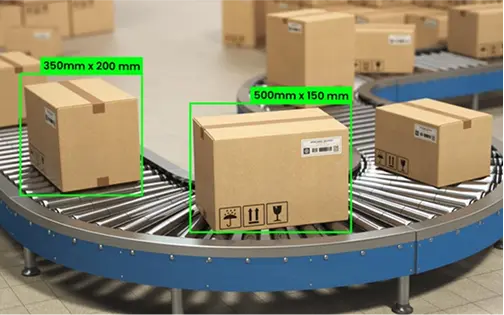

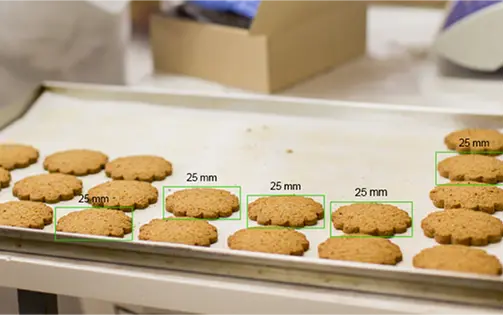

Softweb Solutions’ vision AI accurately measures product dimensions to ensure every item meets exact specifications. It detects size deviations and packaging flaws in real time guaranteeing consistency, quality, and compliance across production.

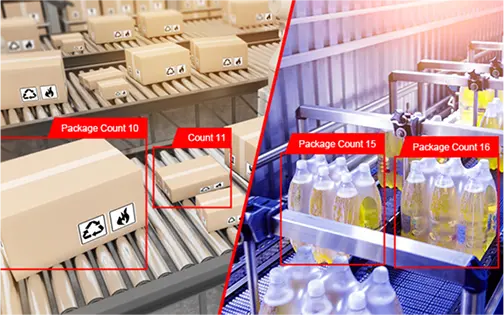

Softweb Solutions’ vision AI delivers precise, real-time product counts on conveyor belts or in storage zones. It eliminates manual errors, enhances inventory accuracy, and streamlines production tracking effortlessly.

Softweb Solutions’ vision AI detects packaging tampering spotting tears, punctures, or reseal marks with high accuracy. It ensures only safe, uncompromised products reach consumers, reinforcing trust and brand integrity.

Softweb Solutions’ vision AI detects heat seal inconsistencies to ensure airtight, reliable food packaging. By catching weak or faulty seals in real time, it helps maintain freshness, prevent contamination, and extend shelf life.

Ready to future-proof your operations with AI?

"Softweb Solutions has been a trusted partner of Elliott Aviation for over 7 years, delivering customized solutions across our operational departments. Their quick delivery, responsive support, and effective system integration have filled gaps left by off-the-shelf options. The simplified GUI they developed has received excellent feedback from internal users and customers alike. Softweb’s insights into emerging technologies help us innovate."

Lonnie Hoodjer,

Sr Director of Business Systems

"Softweb Solutions understood the importance of digital experience and worked tirelessly to enhance our operations and customer engagement. Their expertise and dedication have significantly improved our overall digital presence."

Almir Tucek,

Supervisor, Electronic Media Development, Bosch

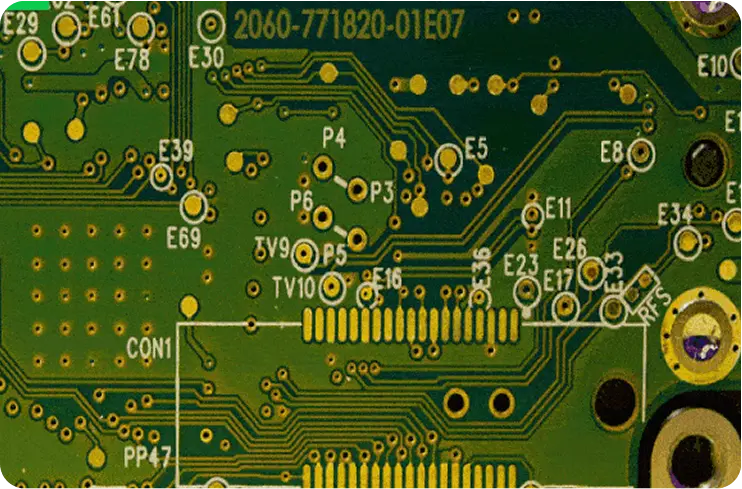

By analyzing images from cameras across 7 factory lines, computer vision helped detect and prevent 112 component failures - something no human could match in speed or precision. With real-time insights, it enables zero-defect production, maximum uptime, and a consistently high-quality output.

Computer vision accelerates medical image analysis, enabling early disease detection and improved patient care. From AI-driven cancer detection to surgical precision and real-time patient monitoring, it empowers smarter, faster healthcare decisions.

Computer vision enables real-time pipeline monitoring to detect leaks caused by corrosion, weld defects, aging, or operator error. By analyzing flow, pressure, and temperature, it ensures quick detection and response - reducing downtime and environmental risks.

Say goodbye to missed defects and inconsistent inspections. Our AI-powered vision system meticulously analyzes PCBs to detect even the smallest anomalies - boosting quality and maximizing yield.

AI-powered anomaly detection is designed to spot when something feels off. It could be a machine showing odd readings, a transaction that doesn’t match usual patterns, or unexpected activity on a network. By watching this data as it happens, businesses get an early warning when issues arise. That way, they can step in quickly, cut down risks, and keep operations steady across different industries.