Employ AI-led Visual Inspection Built for Modern Manufacturing

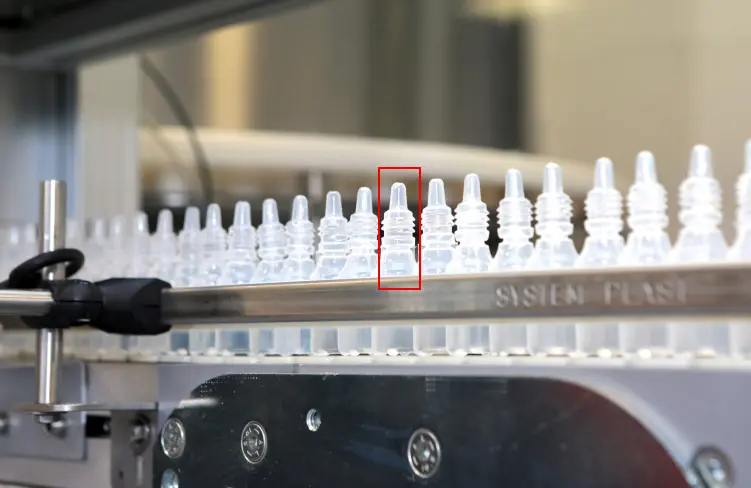

Trace defects in milliseconds, analyze root causes through image data, and automate quality control with a closed-loop system powered by computer vision and machine learning. Detect, classify, and correct issues on the production line with precision.

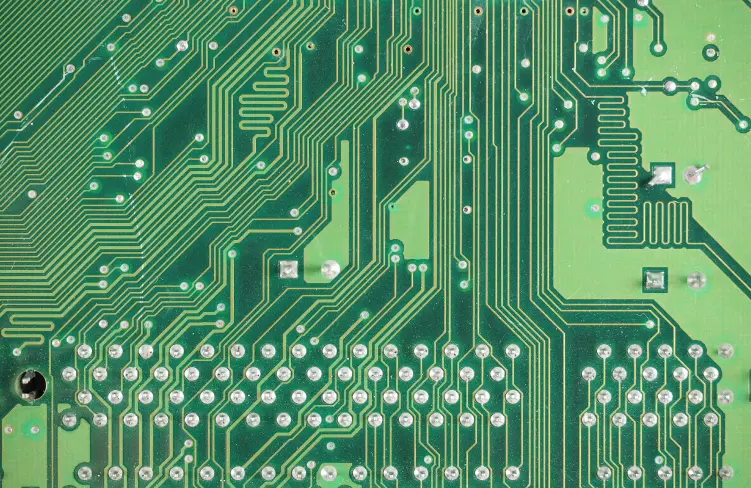

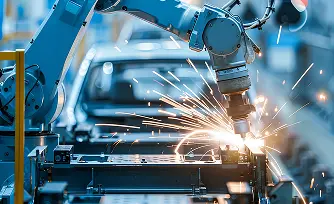

we specialize in segmentation, pattern and feature recognition, and machine learning model retraining. We've delivered AI-driven solutions for automotive and facility management clients using minimal resources and no extra hardware. We’re ready to help you achieve consistent, high-quality manufacturing outcomes.