Introduction of predictive approach and monitoring has to this day, prevented plenty of accidents and saved millions of dollars in plant downtime and equipment failure. Now that asset optimization has gained traction and security has become a major concern for all businesses, predictive maintenance can prove to be the answer to all the qualms that managers had so far.

According to a survey from the U.S. Navy and NASA, only 18% of machine failures are instigated due to age. The remaining 82% are random machine failures, showing the need of predictive maintenance. More often than not, companies fail to recognize the optimum time for maintenance and end up scheduling it either too early, which would increase the cost, or too late, which would decrease the reliability of the machine.

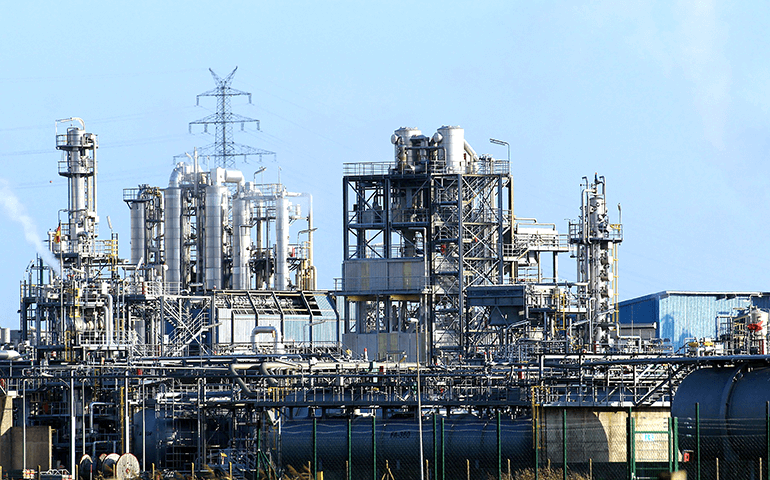

In today’s competitive market, no business can afford unpredicted downtime or accidental machine breakdown. By implementing IoT-powered predictive maintenance (PdM) solutions, oil refining and petrochemical companies can maximize asset performance, increase operational performance, improve product quality, minimize downtime, and reduce costs. PdM analyzes various types of data including log data, measurement data, and failure data to provide accurate information in the form of predictive outcomes.

Predictive maintenance use cases

Predictive maintenance can benefit downstream industries in various manners. In this blog, we will discuss some of the ways in which oil refining and petrochemical companies can use predictive maintenance.

1. Data analytics for refining and petrochemical companies

Data-driven technologies are used to deliver descriptive analytics to assess equipment performance and gain insights into maintenance activities performed across the organization. Data analytics can also deliver predictive analytics to determine sudden machine breakdowns and prescriptive analytics to recommend machine operating conditions and future actions. With data analytics, oil refining and petrochemical companies can gain optimum productivity, increase asset availability, and minimize the maintenance and operational costs.

2. Performance modeling of assets

Performance modeling helps companies to accurately measure the performance of all the machines. It also allows companies to detect degradation in performance at an early stage and prepare a maintenance plan accordingly. It measures key performance indicators (KPIs) including, but not limited to: gross average production, operating cost per barrel, oil spills, operating cash flow, total shareholder return, and greenhouse gas emissions. These KPIs are then compared with the ideal performance to get an overall performance assessment. The effectiveness of the model is measured at regular intervals by evaluating the changes or improvement in the performance of machines.

3. Predicting machine failures using sensor data

On the basis of historical data and currently available information, machine breakdowns can be predicted either through event-based failure prediction or through sensor-based failure prediction. While event-based failure prediction is done upon the historical data of machine performance and past events, sensor-based failure prediction is done based on the information that sensors provide in real-time. The prediction done using such methods can either provide information about machine performance or detect deviation in any of the machine components.

As a manager in charge of reliability and maintenance at an oil refinery plant, would you choose to run your equipment to exhaustion and then replace them? Or would you prefer to establish a system that can let you know in advance which equipment is suffering from damage and when is the ideal time to replace or repair it?

It obviously depends on the type of equipment involved. For noncritical equipment, which is cheaper, installing sensors and monitoring its performance would only add to the operational cost. However, for major equipment such as gas processors, the ability to predict when its components would degrade, and acting on it at the right time, would not only reduce costs, but will also prevent catastrophic failures. If predictive maintenance solutions can help your business in risk mitigation, your investment will pay off.

To know how predictive maintenance can help your business, get in touch with our business analysts.